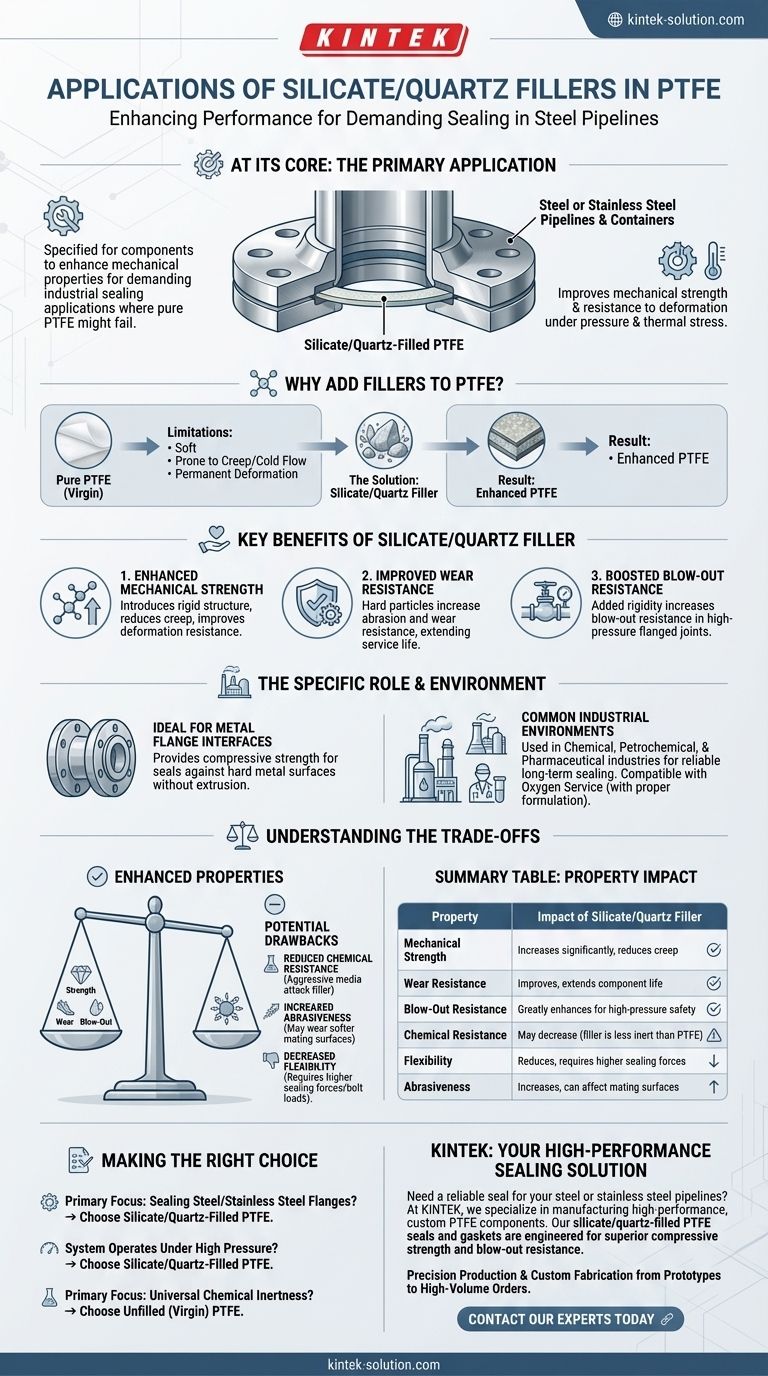

At its core, silicate/quartz-filled Polytetrafluoroethylene (PTFE) is specified for components used in steel or stainless steel pipelines and containers. This specific filler is chosen to enhance the mechanical properties of PTFE, making it more suitable for demanding industrial sealing applications where pure PTFE might fail.

The decision to add a silicate or quartz filler to PTFE is driven by the need to improve its mechanical strength and resistance to deformation, particularly when used as a gasket or seal against hard metal surfaces under pressure and thermal stress.

Why Add Fillers to PTFE?

Pure PTFE is known for its exceptional chemical resistance and low friction, but it has mechanical limitations. It is relatively soft and prone to "creep" or cold flow, where it deforms permanently under a sustained load. Fillers are added to counteract these weaknesses.

Enhancing Mechanical Strength

Fillers introduce a rigid structure within the soft PTFE matrix. This significantly reduces creep and improves the material's ability to resist deformation, a critical factor for maintaining a tight seal over time.

Improving Wear Resistance

Hard filler particles, such as silicate or quartz, dramatically increase PTFE's resistance to abrasion and wear. This extends the service life of components like seals, bearings, and valve seats that experience friction.

Boosting Blow-Out Resistance

In high-pressure applications, particularly in flanged joints, the added rigidity from fillers provides a significant increase in blow-out resistance. This is a crucial safety and reliability feature in the chemical, petrochemical, and pharmaceutical industries.

The Specific Role of Silicate/Quartz

While many fillers exist, silicate/quartz is selected for a particular set of operating conditions. Its primary function is to provide a robust mechanical interface.

Ideal for Metal Flange Interfaces

The key application is for gaskets and seals in steel or stainless steel flange connections. The filler provides the compressive strength needed to create and maintain a seal against the hard metal surface without being extruded or crushed.

Common Industrial Environments

You will find silicate/quartz-filled PTFE components in demanding sectors. These include chemical processing plants, petrochemical facilities, and pharmaceutical production lines where reliable, long-term sealing of pipelines and vessels is essential.

Compatibility with Oxygen Service

With proper formulation and arrangement, certain filled PTFE grades, including some silicate compounds, can be made suitable for use in oxygen applications, which require highly stable and non-reactive materials.

Understanding the Trade-offs

Introducing any filler into pure PTFE involves a careful balance of properties. Enhancing one characteristic often comes at the expense of another.

A Reduction in Chemical Resistance

The primary trade-off is a potential decrease in chemical compatibility. While PTFE is nearly universally inert, the silicate filler is not. Aggressive media could selectively attack the filler material, compromising the integrity of the component.

Increased Abrasiveness

The hardness that improves wear resistance can also make the material more abrasive to softer mating surfaces. This must be considered in the design of dynamic seals or bearings to prevent premature wear on other parts of the assembly.

Decreased Flexibility

Adding a rigid mineral filler will naturally reduce the flexibility and conformability of the base PTFE. This can make installation more difficult and may require higher sealing forces (bolt loads) to be effective.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is sealing steel or stainless steel flanges: Silicate/quartz-filled PTFE provides the ideal combination of compressive strength and creep resistance for a durable, long-lasting seal.

- If your system operates under high pressure: The enhanced blow-out resistance of a filled PTFE like a silicate/quartz compound is a critical design feature for safety and reliability.

- If your primary focus is universal chemical inertness against aggressive media: Unfilled, virgin-grade PTFE remains the superior choice, as any filler can create a potential point of chemical attack.

Choosing a silicate/quartz filler is a deliberate engineering decision to augment PTFE's mechanical properties for challenging industrial sealing duties.

Summary Table:

| Property | Impact of Silicate/Quartz Filler |

|---|---|

| Mechanical Strength | Increases significantly, reduces creep |

| Wear Resistance | Improves, extends component life |

| Blow-Out Resistance | Greatly enhances for high-pressure safety |

| Chemical Resistance | May decrease (filler is less inert than PTFE) |

| Flexibility | Reduces, requires higher sealing forces |

| Abrasiveness | Increases, can affect mating surfaces |

Need a reliable seal for your steel or stainless steel pipelines?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components. Our silicate/quartz-filled PTFE seals and gaskets are engineered to provide superior compressive strength and blow-out resistance, ensuring long-term reliability in the most demanding chemical, petrochemical, and pharmaceutical environments.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us provide the perfect sealing solution for your application. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the pressure and temperature limits for PTFE backup rings? A Guide to Selecting the Right Material

- What are the key properties of PTFE heat sealing bands and wear strips? Enhance System Performance & Reliability

- What advantages do Teflon O-rings offer? Superior Sealing for Extreme Conditions

- What makes PTFE rod suitable for high-temperature applications? Unlock its unique thermal and chemical resilience.

- What makes PTFE liners suitable for high-temperature applications? Unlock Thermal Resilience for Demanding Processes

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- How does PTFE's low friction coefficient benefit impeller performance? Boost Efficiency & Lifespan

- What are some emerging trends in PTFE gasket technology? Innovations in Materials and Manufacturing