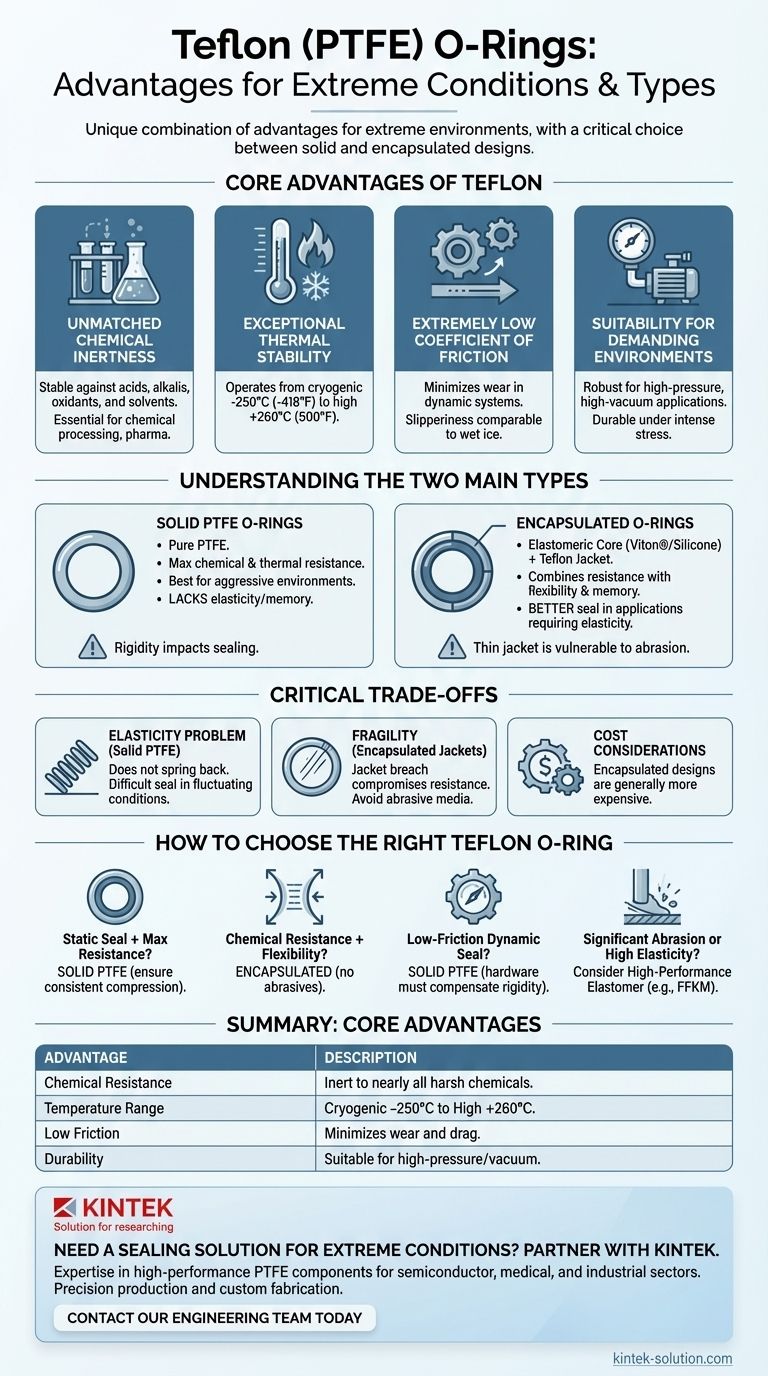

In applications defined by extreme conditions, Teflon® (PTFE) O-rings offer a unique combination of advantages that other materials cannot match. Their primary benefits are a vast operational temperature range, near-universal chemical resistance against acids, solvents, and bases, and an exceptionally low coefficient of friction, which minimizes wear in dynamic systems.

The core decision is not simply choosing Teflon, but understanding which type of Teflon O-ring to use. The material's primary strengths in chemical and thermal resistance come with a critical trade-off in elasticity, leading to two distinct designs—solid and encapsulated—each suited for different mechanical challenges.

The Core Advantages of Teflon (PTFE)

Polytetrafluoroethylene (PTFE), the material known as Teflon, possesses a set of inherent properties that make it an elite choice for sealing in demanding industrial, chemical, and aerospace applications.

Unmatched Chemical Inertness

Teflon is renowned for its stability when exposed to harsh substances. It is effectively inert to nearly all industrial chemicals, including aggressive acids, alkalis, strong oxidants, and organic solvents.

This makes it an indispensable material in chemical processing, pharmaceuticals, and any environment where seal integrity cannot be compromised by chemical attack.

Exceptional Thermal Stability

Teflon O-rings can perform reliably across an extremely broad temperature spectrum.

Solid PTFE seals can withstand conditions ranging from cryogenic lows of -250°C (-418°F) up to sustained high temperatures of +260°C (500°F), far exceeding the limits of most standard elastomers.

Extremely Low Coefficient of Friction

The material has one of the lowest friction coefficients of any solid, often compared to the slipperiness of wet ice.

This non-stick, low-wear characteristic is highly valuable in dynamic applications, such as in rotating shafts or valves, where it reduces drag, heat generation, and component wear over the seal's long service life.

Suitability for Demanding Environments

Beyond temperature and chemicals, Teflon's robust nature makes it suitable for high-pressure and high-vacuum applications where other materials might degrade or outgas. Its durability ensures a reliable and long-lasting seal under intense mechanical stress.

Understanding the Two Main Types of Teflon O-Rings

The primary challenge with Teflon is its rigidity. To address this, two main types of O-rings have been developed, each balancing the material's benefits with its mechanical limitations.

Solid PTFE O-Rings

These O-rings are composed entirely of solid PTFE. They offer the purest form of Teflon's advantages, providing the maximum chemical and thermal resistance.

They are the definitive choice for withstanding the most aggressive environments. However, they lack the memory and elasticity of rubber, a key detail that impacts their sealing capability.

Encapsulated O-Rings

This design features an elastomeric core (such as Viton®/FKM or Silicone) surrounded by a thin, seamless jacket of Teflon.

This hybrid approach combines the chemical resilience and low friction of the Teflon outer layer with the flexibility and memory of the rubber inner core, providing a much better seal in applications that require elasticity.

Acknowledging the Critical Trade-offs

To make an informed decision, you must weigh Teflon's powerful advantages against its practical limitations. Choosing incorrectly can lead to seal failure.

The Elasticity Problem of Solid PTFE

The most significant drawback of solid Teflon is its lack of elasticity. Unlike a rubber O-ring, it does not readily spring back to its original shape after being compressed.

This rigidity can make it difficult to achieve and maintain a perfect seal, especially in applications with fluctuating pressures, thermal cycling, or surface imperfections.

The Fragility of Encapsulated Jackets

While encapsulated O-rings solve the elasticity problem, their thin Teflon jacket is a potential point of failure.

In environments with abrasive media or rough hardware surfaces, the jacket can be scratched or damaged. Any breach compromises the O-ring's chemical resistance, exposing the vulnerable elastomeric core and leading to seal failure.

Cost Considerations

Engineered solutions come at a price. Due to their complex, multi-material construction, Teflon encapsulated O-rings are generally more expensive than both standard elastomeric O-rings and solid PTFE O-rings.

How to Choose the Right Teflon O-Ring

Your final choice depends entirely on the specific demands of your application. Balancing chemical resistance, temperature, pressure, and mechanical movement is key.

- If your primary focus is maximum chemical and thermal resistance in a static seal: A solid PTFE O-ring is a strong candidate, provided you can guarantee consistent and even compression in your design.

- If your primary focus is chemical resistance combined with reliable sealing flexibility: An encapsulated O-ring is the logical choice, but only for applications free from abrasive particles or rough surfaces.

- If your primary focus is a low-friction dynamic seal: Solid PTFE is ideal for its slipperiness, but the hardware design must compensate for its inherent rigidity to maintain a consistent seal.

- If your application involves significant abrasion or requires high elasticity under pressure: You may need to look beyond Teflon to a high-performance elastomer like FFKM, sacrificing some chemical range for superior mechanical robustness.

By understanding these distinctions, you can select a sealing solution that precisely matches your operational demands.

Summary Table:

| Advantage | Description |

|---|---|

| Chemical Resistance | Inert to nearly all acids, solvents, and bases, ensuring seal integrity in harsh environments. |

| Temperature Range | Operates from cryogenic -250°C to high +260°C, far exceeding standard elastomers. |

| Low Friction | Minimizes wear and drag in dynamic applications like rotating shafts and valves. |

| Durability | Suitable for high-pressure and high-vacuum systems, offering long service life. |

Need a Sealing Solution for Extreme Conditions? Partner with KINTEK.

Our expertise in manufacturing high-performance PTFE components—including seals, liners, and labware—is tailored for the semiconductor, medical, laboratory, and industrial sectors. We deliver precision production and custom fabrication, from prototypes to high-volume orders, ensuring your equipment operates reliably in the most demanding environments.

Contact our engineering team today to discuss your specific application requirements and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications