Fundamentally, PTFE heat sealing bands and wear strips are defined by a unique combination of properties that make them ideal for protecting and optimizing moving parts. They offer an extremely low coefficient of friction for superior self-lubrication, high wear resistance for durability, and exceptional chemical inertness across a wide range of fluids. This is coupled with excellent thermal stability and electrical insulating capabilities.

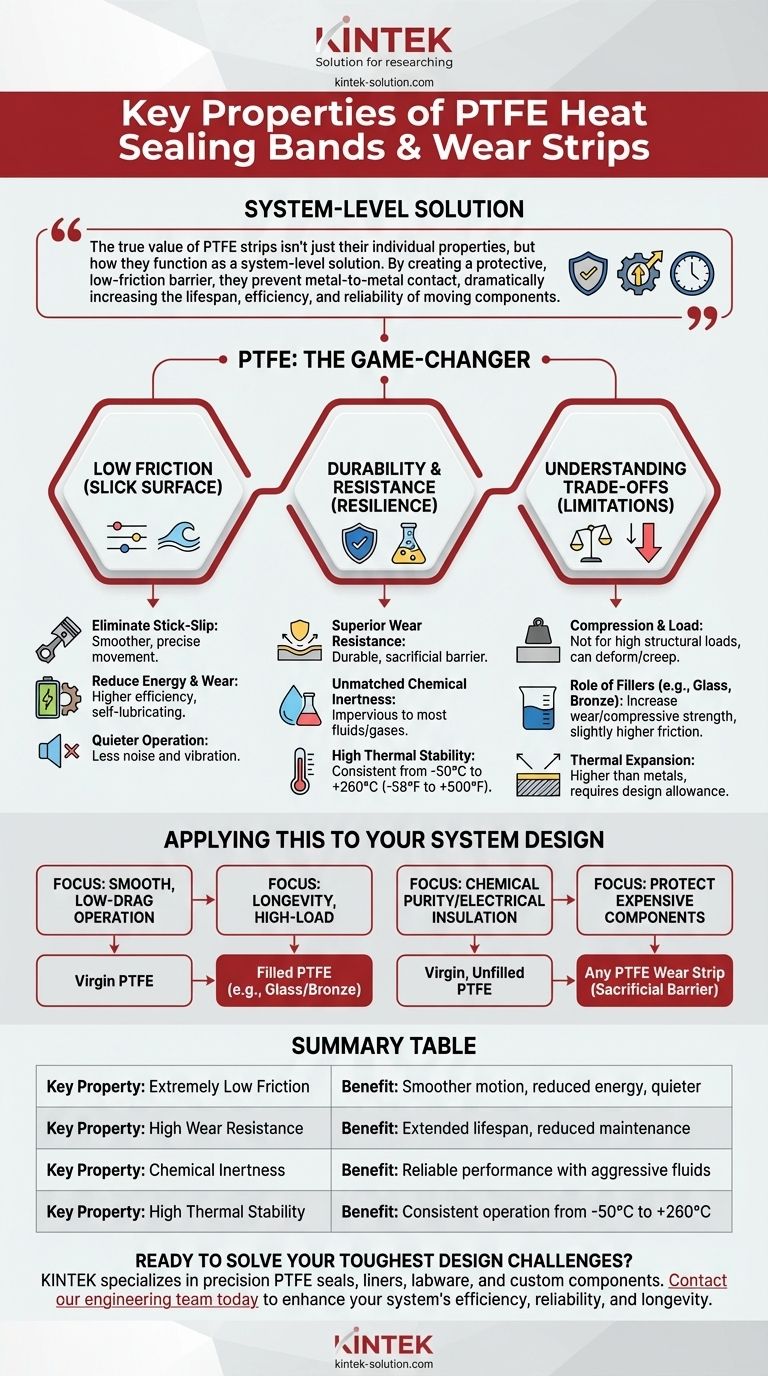

The true value of PTFE strips isn't just their individual properties, but how they function as a system-level solution. By creating a protective, low-friction barrier, they prevent metal-to-metal contact, dramatically increasing the lifespan, efficiency, and reliability of moving components.

Why Low Friction is a System Game-Changer

The most recognized characteristic of PTFE is its slick, non-stick surface. This property has profound effects on the performance of any mechanical system where it is applied.

Eliminating Stick-Slip Behavior

Stick-slip is the jerky motion that occurs when static friction is significantly higher than dynamic friction. PTFE's extremely low and consistent coefficient of friction virtually eliminates this effect.

This ensures smoother, more precise movement, which is critical in applications like hydraulic pistons and conveyor guides.

Reducing Energy and Wear

A lower friction coefficient means less energy is required to initiate and sustain motion.

This directly translates to higher operational efficiency and reduced wear on drive components. The self-lubricating nature means no external lubrication is needed at the contact point.

Enabling Quieter Operation

Friction and vibration are primary sources of operational noise. By providing a smooth, low-drag surface, PTFE strips and guides lead to significantly quieter operation, a key benefit in conveyor systems and other machinery.

The Impact of Material Durability and Resistance

Beyond its low-friction surface, PTFE's resilience to its environment is what makes it a reliable engineering choice for challenging conditions.

Superior Wear Resistance

PTFE strips are designed to withstand tough operating conditions. Their high wear resistance means they serve as a durable, sacrificial barrier, extending the service life of the entire assembly.

Unmatched Chemical Inertness

These components are compatible with and impervious to almost all fluid media and gases. They are only degraded by a few rare substances, such as molten alkaline metals and specific halogenated compounds.

This makes PTFE a safe and reliable choice for systems involving aggressive chemicals or cleaners.

High Thermal Stability

PTFE maintains its integrity across a very wide temperature range, typically from -50°C to +260°C (-58°F to +500°F).

This high melting point and thermal stability ensure consistent performance in applications involving heat, such as heat sealing bands, or in systems with significant temperature fluctuations.

Understanding the Trade-offs and Limitations

While PTFE is an exceptional material, its effectiveness depends on understanding its limitations. No material is a universal solution.

Compression and Load Capacity

While PTFE has high compression resistance for a polymer, it is not a direct replacement for metal in high-load structural applications. It is designed to guide and separate, not bear the primary structural load of a system.

Excessive force can cause the material to deform or "creep" over time, a common characteristic of thermoplastics.

The Role of Fillers

The references mention "virgin PTFE" as well as the possibility of fillers like glass or bronze. Pure, virgin PTFE offers the lowest friction and highest chemical purity.

Adding fillers is a common engineering trade-off. Fillers like glass or bronze are added to increase wear resistance and compressive strength, but this often comes at the cost of a slightly higher coefficient of friction and reduced chemical resistance.

Thermal Expansion

Like all plastics, PTFE has a higher coefficient of thermal expansion than metals. In system designs with tight tolerances and wide temperature swings, this expansion and contraction must be accounted for to prevent binding or failure.

Applying This to Your System Design

Choosing the right material configuration depends entirely on your primary engineering goal.

- If your primary focus is smooth, low-drag operation: Prioritize virgin PTFE for its exceptionally low coefficient of friction, which is key to eliminating stick-slip behavior.

- If your primary focus is longevity in high-load conditions: Consider a filled PTFE variant (e.g., glass or bronze) to gain higher wear and compression resistance, even if it slightly increases friction.

- If your primary focus is chemical purity or electrical insulation: Ensure you are using virgin, unfilled PTFE, as fillers can compromise these specific properties.

- If your primary focus is protecting expensive components: Use any PTFE wear strip as a cost-effective, sacrificial barrier to prevent damaging metal-to-metal contact.

By understanding these core principles, you can confidently specify a PTFE component that directly enhances your system's performance and reliability.

Summary Table:

| Key Property | Benefit for Your System |

|---|---|

| Extremely Low Friction | Smoother motion, reduced energy use, quieter operation |

| High Wear Resistance | Extended component lifespan, reduced maintenance |

| Chemical Inertness | Reliable performance with aggressive fluids and cleaners |

| High Thermal Stability | Consistent operation from -50°C to +260°C (-58°F to +500°F) |

Ready to solve your toughest design challenges with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need the ultra-smooth performance of virgin PTFE or the enhanced durability of a filled compound, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the perfect solution for your application.

Contact our engineering team today to discuss how our PTFE components can enhance your system's efficiency, reliability, and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry