What makes PTFE rod so effective in high-temperature environments is a unique combination of intrinsic thermal resilience and the retention of its other elite properties under heat stress. It can operate continuously at temperatures up to 260°C (500°F) because of its high melting point and exceptional molecular stability. Unlike many materials that become brittle or deform, PTFE maintains its integrity and performance.

PTFE's suitability for high temperatures isn't just about its high melting point. Its true value lies in its ability to maintain its exceptional chemical inertness, low friction, and dimensional stability even when exposed to extreme heat—a combination few other materials can offer.

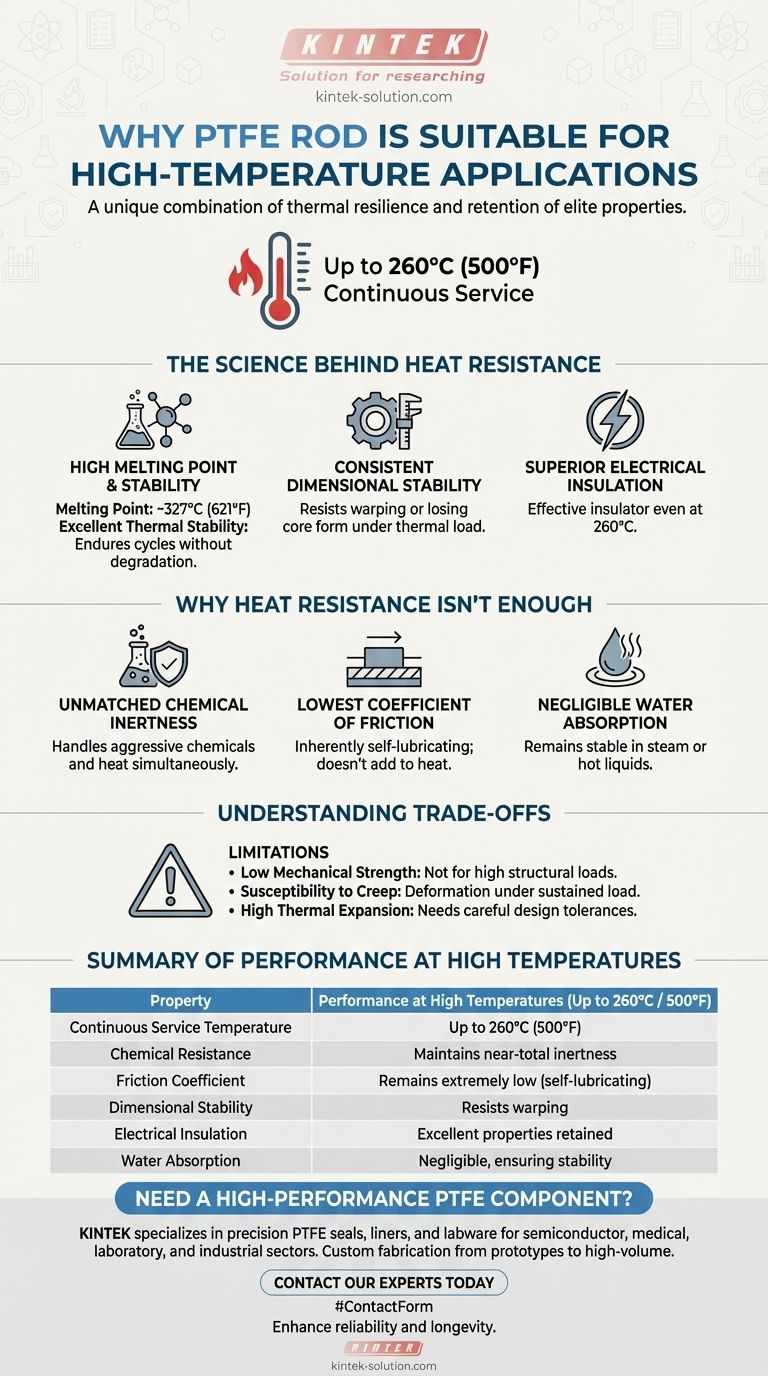

The Science Behind PTFE's Heat Resistance

To understand why PTFE is a go-to choice for demanding applications, we must look beyond a single temperature rating and analyze how the material behaves under thermal load.

High Melting Point and Thermal Stability

PTFE has a very high melting point for a polymer, around 327°C (621°F). This gives it a high continuous service temperature of 260°C (500°F).

More importantly, it has excellent thermal stability. This means it can endure repeated heating and cooling cycles within its operating range without degrading, breaking down, or losing its fundamental properties.

Consistent Dimensional Stability

A critical factor in high-temperature engineering is how a material changes shape. Many materials, especially metals, expand significantly when heated, which can cause parts to seize or fail.

While PTFE does expand, it resists warping or losing its core strength and form at high temperatures. This allows components like bushings and seals to perform reliably where others might fail.

Superior Electrical Insulation

PTFE is an exceptional electrical insulator. In many high-temperature environments, heat is generated by or coexists with electrical components.

The material's ability to insulate effectively even at 260°C makes it invaluable for high-performance wiring, connectors, and insulators in demanding electronic and industrial settings.

Why Heat Resistance Alone Isn't Enough

The true advantage of PTFE rod is that its other world-class properties are not compromised by heat. This synergy is what makes it a powerful problem-solving material.

Unmatched Chemical Inertness

High-temperature industrial processes frequently involve aggressive chemicals, acids, or solvents.

PTFE is almost entirely chemically inert. Its ability to handle both extreme heat and corrosive substances simultaneously makes it ideal for seals, gaskets, and linings in chemical processing and manufacturing.

The Lowest Coefficient of Friction

Heat is often a direct result of friction between moving parts. PTFE has one of the lowest coefficients of friction of any solid material, making it inherently self-lubricating.

In a high-temperature application like a bearing or slide plate, this means PTFE doesn't add to the heat problem. It allows for smooth, dry-running operation where traditional lubricants would burn off or fail.

Negligible Water Absorption

In environments involving steam or hot liquids, some materials can absorb moisture, causing them to swell, soften, or degrade.

PTFE has extremely poor water absorption. It remains stable and effective, ensuring consistent performance and component longevity regardless of humidity or direct fluid contact.

Understanding the Trade-offs and Limitations

No material is perfect. To use PTFE effectively, it's crucial to be aware of its limitations, especially in the context of mechanical design.

Low Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE is a relatively soft material. It has low tensile strength and is not suitable for high-load structural components.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can be prone to "creep," which is a slow, permanent deformation. This must be accounted for during the design of parts that are under constant compression, like seals.

High Thermal Expansion

While dimensionally stable in its form, PTFE has a coefficient of thermal expansion that is significantly higher than metals. Engineers must design parts with appropriate tolerances to account for this expansion and contraction during temperature cycles.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary demands of your project.

- If your primary focus is combined heat and chemical resistance: PTFE is an industry-leading choice for seals, gaskets, and linings in corrosive, high-temperature environments.

- If your primary focus is low-friction performance at high temperatures: PTFE's self-lubricating properties make it ideal for bushings, bearings, and slide plates where traditional lubricants would fail.

- If your primary focus is high mechanical strength under heat: You should evaluate other materials like PEEK, Torlon, or specific metals, as PTFE's softness is a significant limiting factor for structural loads.

By understanding this complete performance profile, you can confidently specify PTFE for applications where its unique strengths will deliver exceptional reliability.

Summary Table:

| Property | Performance at High Temperatures (Up to 260°C / 500°F) |

|---|---|

| Continuous Service Temperature | Up to 260°C (500°F) |

| Chemical Resistance | Maintains near-total inertness, resists corrosive substances |

| Friction Coefficient | Remains extremely low, providing self-lubrication |

| Dimensional Stability | Resists warping and maintains form under thermal cycling |

| Electrical Insulation | Excellent insulating properties are retained |

| Water Absorption | Negligible, ensuring stability in humid/steam environments |

Need a high-performance PTFE component that can withstand extreme heat and harsh chemicals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to your specific thermal and chemical challenges.

Contact our experts today to discuss how our PTFE components can enhance the reliability and longevity of your high-temperature applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications