At its core, PTFE's exceptionally low coefficient of friction directly enhances impeller performance by reducing the two primary enemies of any mechanical system: wasted energy and physical wear. This translates into a more efficient and durable component that consumes less power and lasts significantly longer, especially in high-speed or continuous-duty applications.

The true benefit of PTFE on an impeller is not just its "slipperiness," but its ability to create a self-lubricating surface at a molecular level. This fundamentally reduces parasitic drag and wear, converting energy that would be lost to heat and friction into productive fluid movement.

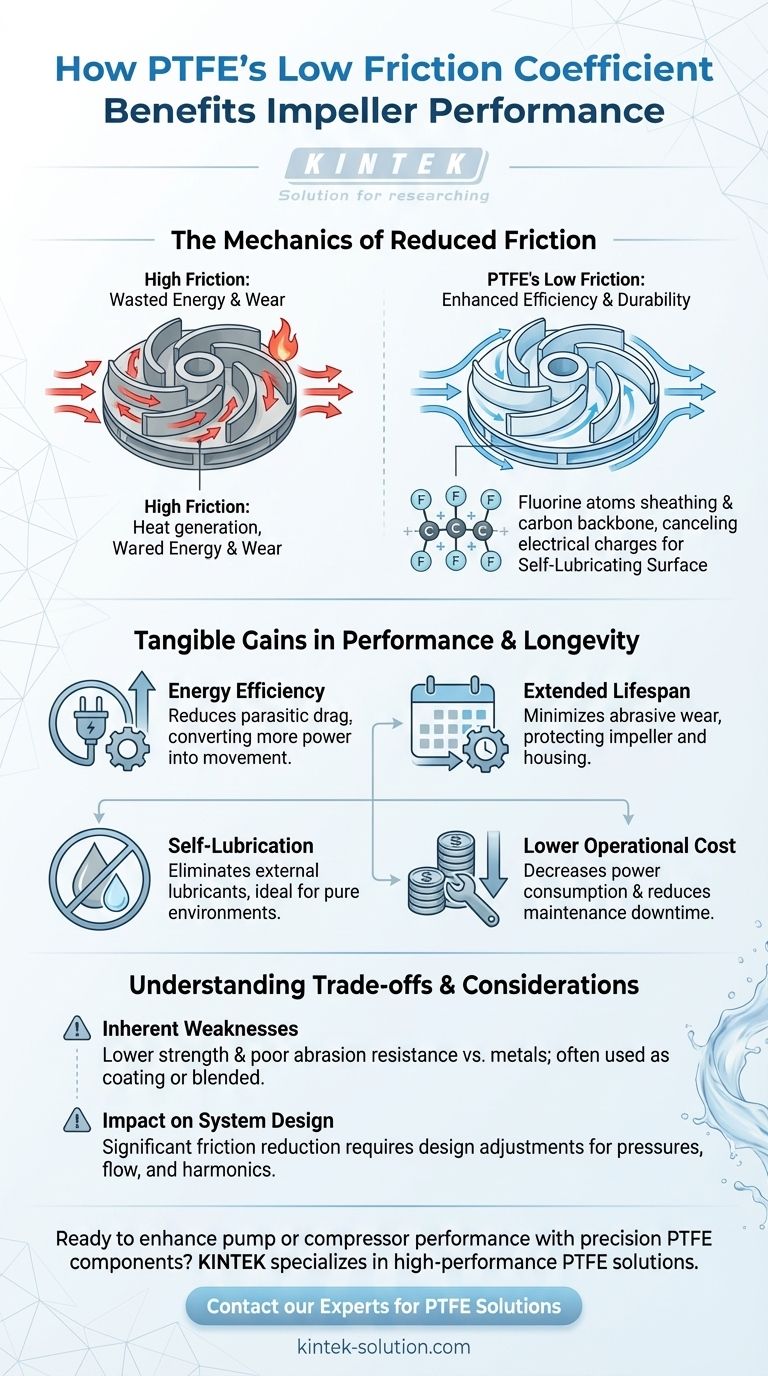

The Mechanics of Reduced Friction in Impellers

To understand the performance gains, we must first look at the unique properties of Polytetrafluoroethylene (PTFE) and how they function in a dynamic fluid system.

The Molecular Basis of Low Friction

The secret to PTFE's low friction lies in its molecular structure. The fluorine atoms create a tight, uniform sheath around the carbon backbone.

This symmetrical arrangement causes the electrical charges (dipole moments) of neighboring molecules to cancel each other out, resulting in a surface with very low energy. Consequently, other materials have very little to "grab" onto, allowing them to slide past with minimal resistance.

Translating Low Friction into Energy Efficiency

Every bit of friction in a pump or compressor is a force that the motor must overcome before it can do useful work. This wasted effort manifests as heat and noise.

By minimizing the friction between the rotating impeller and the surrounding fluid or housing, a PTFE coating or component drastically cuts these energy losses. This means more of the motor's power is dedicated to the primary task: moving the fluid.

The Self-Lubricating Advantage

PTFE's properties provide a constant state of lubrication without needing external oils or greases. This is known as a self-lubricating characteristic.

This is invaluable in applications where added lubricants are unacceptable, such as in food processing, pharmaceutical production, or medical devices, as it eliminates a potential source of contamination.

Tangible Gains in Performance and Longevity

The theoretical benefits of low friction translate into measurable improvements in reliability and operational cost.

Extending Component Lifespan

Friction is the direct cause of mechanical wear. As an impeller spins, friction slowly erodes its surfaces and can also damage the stationary pump housing.

PTFE's low-friction surface acts as a protective barrier, minimizing this abrasive wear. This extends the service life of not only the impeller itself but also the adjacent components, leading to a more robust and long-lasting system.

Lowering Maintenance and Operational Costs

A longer component lifespan directly results in lower maintenance costs and less system downtime.

This is especially critical for equipment that is difficult to access or integral to a continuous production line, where a shutdown for repairs can be extremely costly. The improved energy efficiency also leads to direct, cumulative savings on electricity bills over the equipment's lifetime.

Understanding the Trade-offs and Considerations

While highly beneficial, PTFE is not a universal solution. Its unique properties come with important engineering trade-offs.

Inherent Material Weaknesses

The same molecular structure that gives PTFE its low friction also results in relatively low strength and poor abrasion resistance compared to metals or harder polymers.

In applications with highly abrasive slurries or high-impact conditions, pure PTFE may wear away quickly. It is often used as a coating or blended with other materials (like glass or carbon) to enhance its durability.

Impact on System Design

The significant reduction in friction is a factor that must be accounted for in the overall system design.

For instance, much like how PTFE-coated fasteners require different torque specifications to achieve the correct clamping force, an impeller with radically different frictional characteristics will interact with the fluid and housing differently. This can affect system pressures, flow rates, and vibrational harmonics, all of which must be considered by the design engineer.

Making the Right Choice for Your Application

Selecting PTFE for an impeller component is a strategic decision based on your primary operational goal.

- If your primary focus is energy efficiency: PTFE is ideal for high-speed or continuous-duty systems where even small friction reductions lead to significant cumulative power savings.

- If your primary focus is equipment longevity: In moderately clean fluid systems, PTFE's ability to reduce wear can drastically extend maintenance intervals and the overall life of the pump.

- If your primary focus is product purity: The self-lubricating nature of PTFE makes it an excellent choice for sterile applications in the food, pharmaceutical, and medical industries.

Ultimately, incorporating PTFE is a deliberate engineering choice to minimize parasitic losses and maximize the operational lifespan of critical rotating equipment.

Summary Table:

| Benefit | Impact on Impeller Performance |

|---|---|

| Energy Efficiency | Reduces parasitic drag, converting more motor power into fluid movement. |

| Extended Lifespan | Minimizes abrasive wear on the impeller and housing. |

| Self-Lubrication | Eliminates need for external lubricants, ideal for pure environments. |

| Lower Operational Cost | Decreases power consumption and reduces maintenance downtime. |

Ready to enhance your pump or compressor performance with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures your impellers and systems achieve maximum efficiency and durability.

Contact our experts today to discuss how our PTFE solutions can benefit your specific application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments