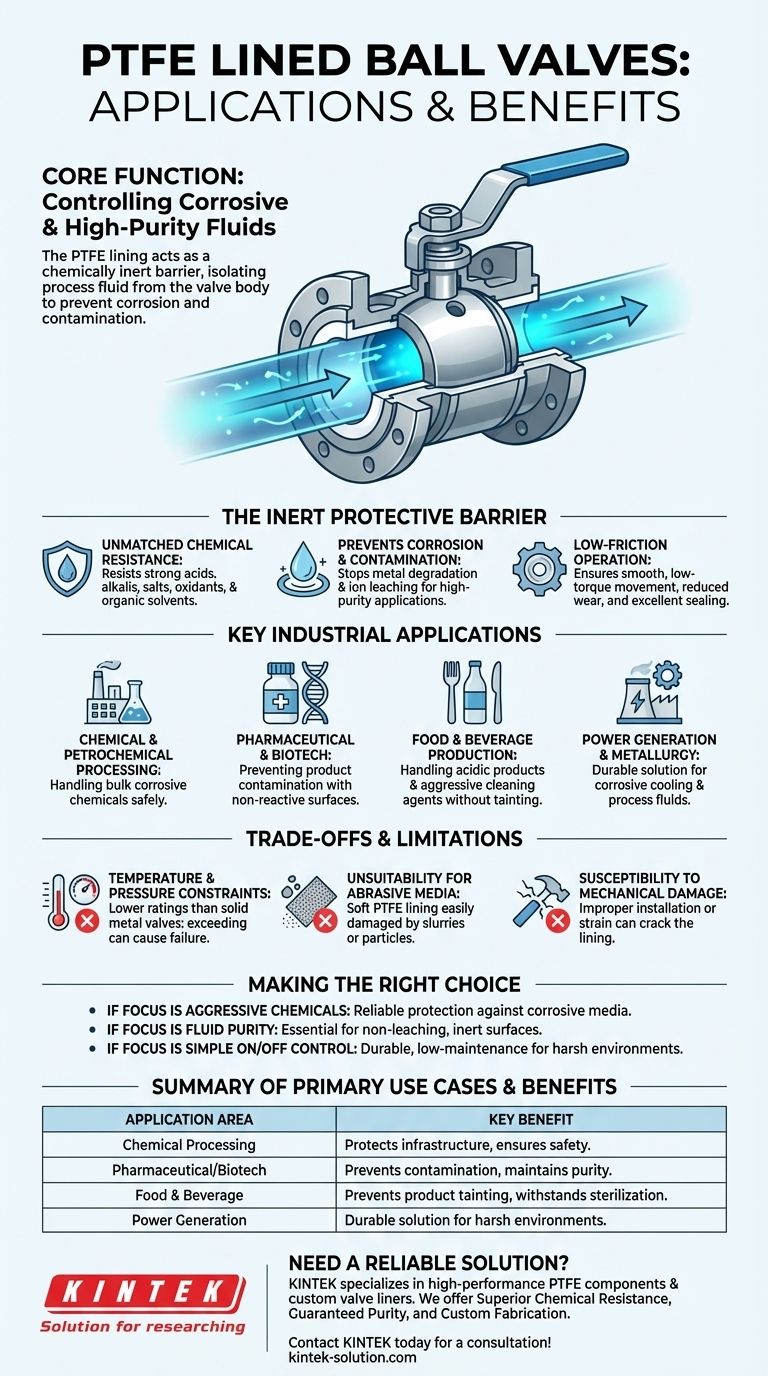

At their core, PTFE lined ball valves are used to control the flow of highly corrosive or high-purity fluids. They are essential in industries where standard metal valves would quickly corrode and fail, such as chemical processing, pharmaceuticals, food and beverage, and power generation. The PTFE lining acts as a chemically inert barrier, protecting the valve's structural metal components from aggressive media like acids, alkalis, and solvents.

The fundamental purpose of a PTFE lined ball valve is not just to control flow, but to isolate the process fluid from the valve's body. This creates a corrosion-proof and non-contaminating pathway, ensuring both system longevity and fluid purity.

The Core Principle: An Inert, Protective Barrier

The effectiveness of these valves stems from the unique properties of Polytetrafluoroethylene (PTFE), the material used for the lining.

### Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers available. This means it does not react with the vast majority of industrial chemicals.

This property makes it the ideal choice for handling aggressive media, including strong acids, alkalis, salts, oxidants, and organic solvents that would rapidly degrade even specialized metal alloys.

### Preventing Corrosion and Contamination

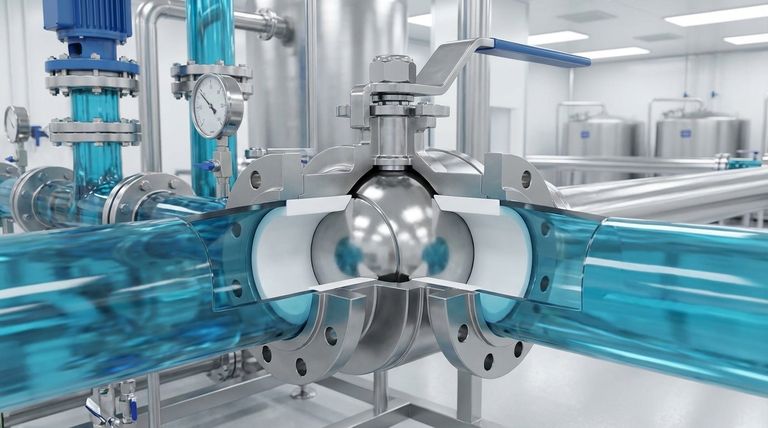

The PTFE is applied as a thick, continuous lining to all wetted surfaces of the valve, primarily the body and the ball.

This lining physically separates the fluid from the valve's carbon or stainless steel body. This prevents chemical attacks on the metal and stops metal ions from leaching into the fluid, which is critical for high-purity applications.

### Low-Friction Operation

PTFE has an extremely low coefficient of friction. This results in a smooth, low-torque operation when opening and closing the valve.

This reduces the wear on the valve's seats and seals, leading to a longer service life and excellent sealing performance that prevents leaks.

Key Industrial Applications

The combination of corrosion resistance and purity makes PTFE lined ball valves indispensable across several critical sectors.

### Chemical and Petrochemical Processing

This is the primary application. These valves are used extensively in pipeline systems to manage the transfer of bulk corrosive chemicals, ensuring the safety and integrity of the plant infrastructure.

### Pharmaceutical and Biotech

In these industries, preventing product contamination is paramount. PTFE lined valves provide a smooth, non-reactive surface that does not interfere with sensitive biological or chemical compounds.

### Food and Beverage Production

These valves are used to handle not only acidic food products but also the aggressive cleaning and sterilization chemicals used to maintain hygienic conditions, without degrading the equipment or tainting the product.

### Power Generation and Metallurgy

Various processes in these heavy industries involve the use of corrosive fluids for cooling, processing, or waste treatment. PTFE lined valves offer a durable solution for controlling these challenging media.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. An objective assessment requires understanding their operational limits.

### Temperature and Pressure Constraints

PTFE has a lower operating temperature and pressure rating than solid metal valves. Exceeding these limits can cause the lining to deform or fail, leading to a catastrophic loss of containment.

### Unsuitability for Abrasive Media

The primary strength of PTFE is its chemical resistance, not its hardness. The soft lining can be easily damaged or worn away by fluids containing abrasive particles, such as slurries or suspended solids.

### Susceptibility to Mechanical Damage

The integrity of the lining is crucial. Improper installation, excessive pipe strain, or mechanical shock can crack or delaminate the PTFE, exposing the metal body to the corrosive fluid and defeating the valve's purpose.

Making the Right Choice for Your Application

Selecting the correct valve depends entirely on the specific demands of your system.

- If your primary focus is handling aggressive chemicals: A PTFE lined ball valve provides the most reliable and cost-effective protection against a wide spectrum of corrosive media.

- If your primary focus is maintaining absolute fluid purity: The inert, non-leaching surface of the PTFE lining is essential for applications in the pharmaceutical, food, and semiconductor industries.

- If your primary focus is simple ON/OFF control in a harsh environment: The durability and low-maintenance design of these valves ensure long-term operational reliability for corrosive fluid isolation.

Ultimately, choosing a PTFE lined ball valve is a strategic decision to prioritize chemical compatibility and system integrity over raw mechanical strength.

Summary Table:

| Application Area | Primary Use Case | Key Benefit |

|---|---|---|

| Chemical Processing | Handling bulk corrosive chemicals (acids, alkalis, solvents) | Protects infrastructure from corrosion, ensures safety |

| Pharmaceutical/Biotech | Managing sensitive biological/chemical compounds | Prevents contamination, maintains product purity |

| Food & Beverage | Controlling acidic products & aggressive cleaning agents | Prevents product tainting, withstands sterilization |

| Power Generation | Managing corrosive cooling/process fluids | Durable solution for harsh industrial environments |

Need a reliable valve solution for corrosive or high-purity applications?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom ball valve liners. We serve the semiconductor, medical, laboratory, and industrial sectors by providing:

- Superior Chemical Resistance: Ensure your system's integrity against aggressive media.

- Guaranteed Purity: Protect sensitive processes from contamination with our inert PTFE surfaces.

- Custom Fabrication: From initial prototypes to high-volume production runs, we deliver solutions tailored to your exact specifications.

Let's discuss how our PTFE expertise can enhance your fluid handling system. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main limitations of Teflon machining? Navigating Softness, Creep, and Thermal Expansion

- What are the three main factors to consider when selecting ball valve seat materials? Ensure System Reliability

- What are the three basic design elements of PTFE seals? Unlock Superior Sealing Performance

- What makes PTFE flange gaskets a better choice for operational efficiency? Maximize uptime and cut costs

- What is FEP and how does it differ from PTFE? Key Differences in Performance & Manufacturing

- Which material exhibits the best non-wetting characteristics among Teflon coatings? PTFE is the Clear Winner

- What maintenance advantages do PTFE compensators offer? Maximize Uptime with Self-Cleaning Design

- How does the self-lubricating property of PTFE rotary shaft seals benefit industrial applications? Achieve Maintenance-Free, High-Performance Sealing