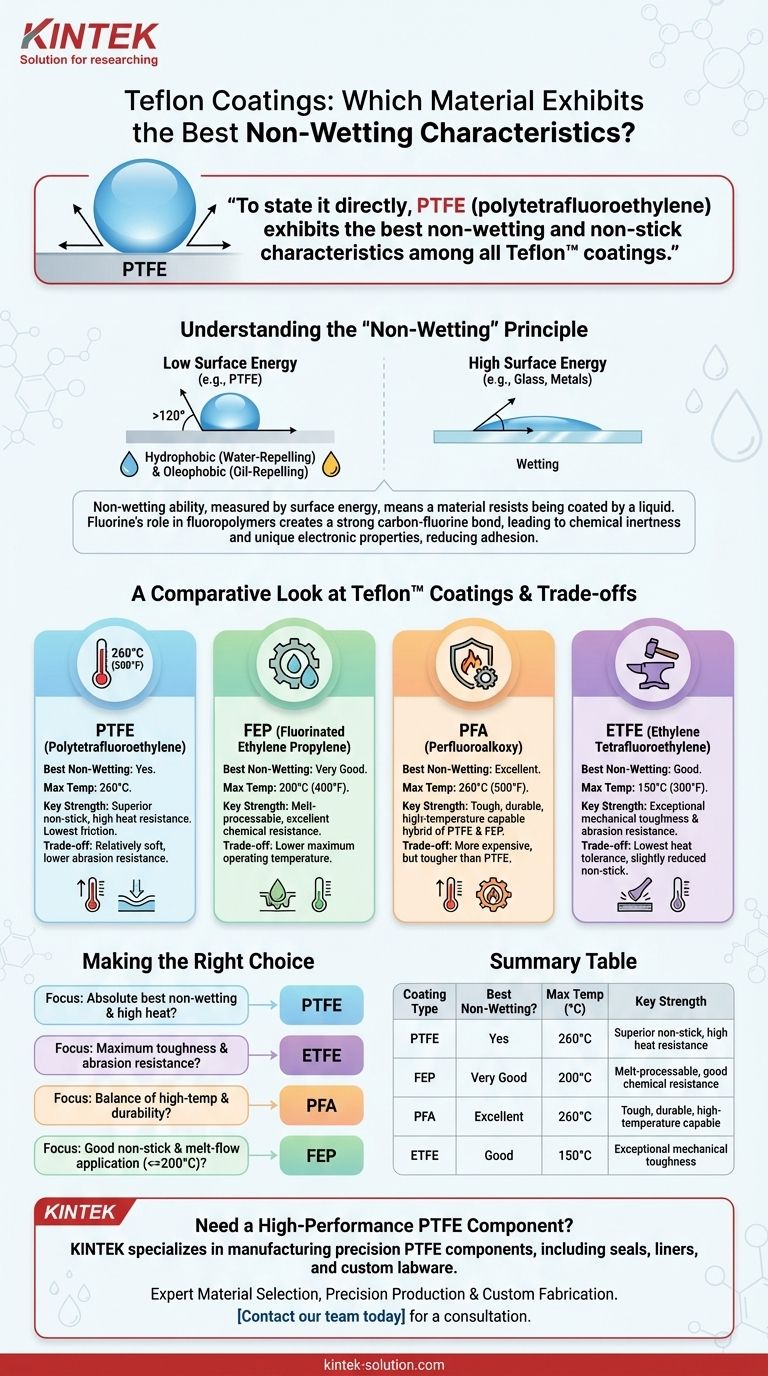

To state it directly, PTFE (polytetrafluoroethylene) exhibits the best non-wetting and non-stick characteristics among all Teflon™ coatings. Its unique molecular structure results in an extremely low surface energy, which is why it is the benchmark material for applications where preventing adhesion is the primary goal.

While PTFE offers superior non-wetting properties, selecting the right coating is not a simple matter of choosing the best non-stick surface. The optimal choice for your application depends on a critical balance of non-wetting performance, temperature resistance, chemical exposure, and mechanical durability.

Understanding the "Non-Wetting" Principle

What Non-Wetting Really Means

The term "non-wetting" refers to a material's ability to resist being coated by a liquid. This is scientifically quantified by measuring surface energy.

Materials with low surface energy, like PTFE, force liquids to form beads with a high contact angle instead of spreading out. This is the physical principle behind its exceptional hydrophobicity (water-repelling) and oleophobicity (oil-repelling) properties.

The Role of Fluorine

All Teflon™ coatings are fluoropolymers, meaning their molecular structure is built around a carbon backbone protected by a sheath of fluorine atoms.

The carbon-fluorine bond is incredibly strong and stable. This chemical inertness and the unique electronic properties of fluorine are what give this entire family of materials their characteristic resistance to adhesion.

A Comparative Look at Teflon™ Coatings

While they share a common chemistry, each type of Teflon™ offers a distinct profile of properties.

PTFE (Polytetrafluoroethylene)

PTFE is the original and most well-known fluoropolymer coating. It provides the lowest coefficient of friction of any solid material.

It boasts exceptional chemical stability and can withstand high continuous service temperatures, often up to 260°C (500°F). Its primary limitation is that it is relatively soft and has lower abrasion resistance compared to other fluoropolymers.

FEP (Fluorinated Ethylene Propylene)

FEP offers excellent non-wetting and chemical resistance, nearly on par with PTFE. Its key advantage is that it is melt-processable.

However, it comes with a lower maximum operating temperature, typically around 200°C (400°F). This makes it suitable for applications where ease of application is important and extreme heat is not a factor.

PFA (Perfluoroalkoxy)

PFA can be seen as a high-performance hybrid, combining the high-temperature resistance of PTFE with the melt-processability of FEP.

It is tougher and more durable than PTFE, making it an excellent choice for demanding chemical processing environments that also require non-stick surfaces.

ETFE (Ethylene Tetrafluoroethylene)

ETFE is known for its exceptional mechanical toughness and abrasion resistance, which is significantly higher than that of PTFE, FEP, or PFA.

While its non-wetting properties are very good, they are not quite as elite as PTFE's. Its temperature resistance is also lower, typically around 150°C (300°F). Tefzel™ is a common brand name for ETFE.

Understanding the Trade-offs

Choosing a coating solely based on its non-wetting capability can lead to failure. You must consider the entire operational environment.

Temperature vs. Durability

There is often an inverse relationship between maximum operating temperature and mechanical toughness.

PTFE provides the highest heat resistance but is the softest. ETFE offers the best durability and abrasion resistance but has the lowest heat tolerance of the group.

Chemical Resistance

All of these coatings offer superb chemical resistance, but PFA and PTFE generally lead the pack due to their fully fluorinated molecular structure. They are inert to nearly all industrial chemicals and solvents.

Application and Film Thickness

Because PTFE is not melt-processable, it is applied as a liquid dispersion and then sintered (baked) at high temperatures. In contrast, FEP and PFA can be melt-flowed to create smooth, non-porous films. This can be an important distinction for applications requiring a pinhole-free barrier.

Making the Right Choice for Your Application

To select the correct coating, you must prioritize your primary engineering requirement.

- If your primary focus is the absolute best non-wetting and non-stick performance: Choose PTFE, especially if high-temperature resistance is also needed.

- If your primary focus is maximum toughness and abrasion resistance: Choose ETFE, accepting its lower temperature limit and slightly reduced non-stick properties.

- If your primary focus is a balance of high-temperature performance and durability: Choose PFA, as it provides an excellent compromise between the properties of PTFE and FEP.

- If your primary focus is good non-stick properties with easier, melt-flow application: Choose FEP, provided the service temperature does not exceed 200°C.

Ultimately, a successful outcome depends on matching the specific strengths of the coating material to the unique demands of your environment.

Summary Table:

| Coating Type | Best Non-Wetting? | Max Temp (°C) | Key Strength |

|---|---|---|---|

| PTFE | Yes | 260°C | Superior non-stick, high heat resistance |

| FEP | Very Good | 200°C | Melt-processable, good chemical resistance |

| PFA | Excellent | 260°C | Tough, durable, high-temperature capable |

| ETFE | Good | 150°C | Exceptional mechanical toughness |

Need a High-Performance PTFE Component?

Choosing the right fluoropolymer is critical for your application's success. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Expert Material Selection: Leverage our deep knowledge of PTFE, FEP, PFA, and ETFE to select the optimal coating for your specific temperature, chemical, and durability requirements.

- Precision Production & Custom Fabrication: From initial prototypes to high-volume orders, we ensure every part meets your exact specifications for performance and reliability.

Let's discuss your project requirements and ensure you get the best non-wetting solution. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability