The three fundamental design elements of a PTFE seal are the pressure-actuated jacket, typically U-shaped; a metal spring loading device, often called an energizer; and the high-performance polymeric material from which the jacket is made. These components work in unison to create a highly effective seal capable of withstanding demanding conditions where traditional elastomeric seals might fail.

The core principle of a PTFE seal is synergy. A durable, low-friction PTFE jacket provides the sealing barrier, while an internal spring provides constant mechanical energy, ensuring a reliable seal across a wide range of pressures, temperatures, and dynamic conditions.

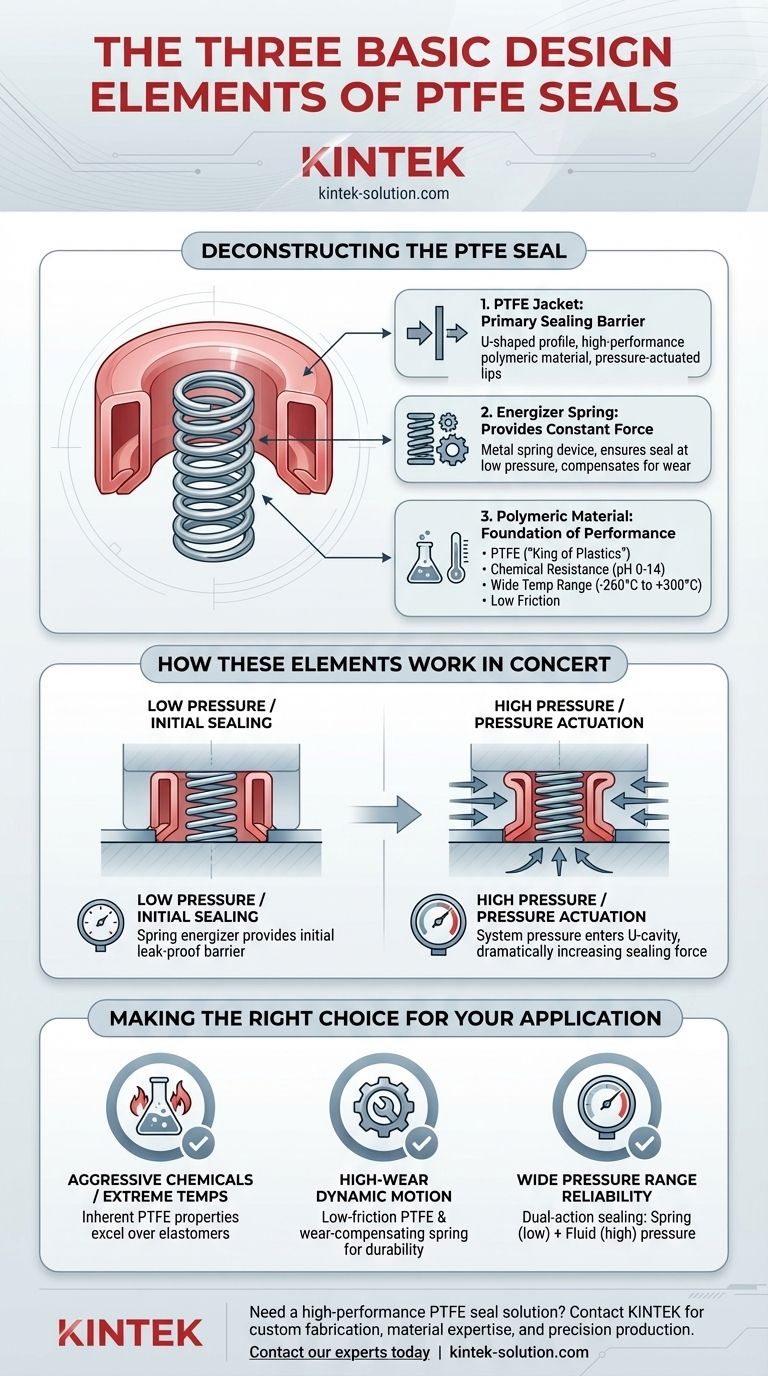

Deconstructing the PTFE Seal

To understand how these seals function, it's essential to analyze the specific role each of the three core elements plays in the system.

The PTFE Jacket: The Primary Sealing Barrier

The most prominent feature of the seal is its jacket, machined from a blend of high-performance polymeric materials, with PTFE being the primary component.

Its common U-shaped profile is purpose-built. This shape creates two sealing lips that allow system pressure to enter the cavity, energizing the seal and increasing the sealing force in proportion to the pressure.

The Energizer Spring: Providing Constant Force

Inside the jacket lies a metal spring loading device. This component is critical for the seal's performance, especially in low-pressure or static situations.

The spring exerts a constant outward force on the lips of the jacket. This ensures a tight seal is maintained even without system pressure, and it actively compensates for material wear, thermal expansion, and minor hardware misalignments over the seal's lifespan.

The Polymeric Material: The Foundation of Performance

PTFE, often called the "King of Plastics," forms the basis of the seal jacket for several key reasons. Its properties define the seal's capabilities.

Key characteristics include exceptional chemical resistance (pH 0-14), a very wide operating temperature range (-260°C to +300°C), and an extremely low coefficient of friction. This makes the material ideal for dynamic applications and harsh media.

How These Elements Work in Concert

The genius of the design is how the jacket and spring interact with system pressure to create a dynamic and responsive seal.

Initial Sealing at Low Pressure

At zero or very low system pressure, the spring energizer does all the work. It mechanically pushes the jacket lips against the sealing surfaces, creating the initial leak-proof barrier.

Pressure Actuation at High Pressure

As system pressure increases, the fluid enters the U-shaped cavity of the jacket. This pressure acts on the inner surfaces of the lips, dramatically increasing the sealing force against the hardware. The seal becomes stronger as pressure rises.

Compensation for Wear and Imperfections

The spring's constant outward push ensures the sealing lips stay in contact with the shaft or bore, even as the soft PTFE material slowly wears away from dynamic motion. This self-adjusting nature is a key reason for the seal's long service life.

Common Pitfalls and Design Considerations

While powerful, PTFE seals require proper implementation to function correctly. Their unique material properties introduce trade-offs that must be managed.

Hardware and Cavity Design

The design of the sealing pocket, or groove, is critical. Because PTFE is a relatively rigid plastic, complex machined pockets can make installation difficult, requiring the seal to be bent or twisted, which can cause damage.

Using features like flanges or retainers can simplify installation and ensure the seal is properly seated without being compromised.

The Challenge of Material Stiffness

PTFE has a high flexural modulus compared to rubber. To compensate for this stiffness, especially in applications with potential shaft run-out, seal designs often incorporate uniformly thin cross-sections.

These thin sections provide needed flexibility and also help minimize the effects of thermal expansion and compressive creep, maintaining a stable and controlled contact pattern on the sealing surface.

Avoiding Installation Errors

Proper installation is paramount. Surfaces must be clean, and the correct tools should be used. Over-tightening is a common mistake that can deform the soft PTFE jacket, creating a leak path and ruining the seal before it ever enters service.

Making the Right Choice for Your Application

Selecting the correct seal configuration depends entirely on your primary operational challenge.

- If your primary focus is aggressive chemicals or extreme temperatures: The inherent material properties of the PTFE jacket make it the superior choice over standard elastomers.

- If your primary focus is high-wear dynamic or reciprocating motion: The combination of the low-friction PTFE and the wear-compensating spring provides exceptional durability and a long service life.

- If your primary focus is reliability across a wide pressure range: The dual-action sealing from the spring (at low pressure) and system fluid (at high pressure) ensures consistent performance.

By understanding how its three core elements function together, you can effectively leverage the unique strengths of a spring-energized PTFE seal for your most demanding applications.

Summary Table:

| Design Element | Key Function | Key Characteristics |

|---|---|---|

| PTFE Jacket | Primary sealing barrier | U-shaped profile, pressure-actuated, provides sealing lips |

| Energizer Spring | Provides constant force | Compensates for wear, ensures seal at low pressure |

| Polymeric Material | Foundation of performance | Chemical resistance, wide temperature range, low friction |

Need a high-performance PTFE seal solution for your demanding application?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Our expertise ensures your seals are designed and fabricated to meet the exact challenges of your industry—whether it's semiconductor, medical, laboratory, or industrial applications.

We deliver reliable performance through:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Leveraging PTFE's full potential for chemical resistance and extreme temperatures.

- Precision Production: Ensuring optimal seal geometry and performance.

Contact our experts today to discuss your specific requirements and let KINTEK provide the sealing solution you can depend on.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE Bellows suitable for electroplating processes? Master Harsh Chemical & Thermal Environments

- How are PTFE gaskets used in the petroleum and chemical industry? Ensure Leak-Proof Sealing in Harsh Environments

- What are the typical properties of 25% glass-filled Teflon balls? Enhance Durability & Stability

- What factors should be considered when choosing a gasket material? A Guide to Reliable Sealing

- What are the features and applications of PTFE lip gaskets? A Guide to Sealing in Extreme Environments

- How are Teflon rods utilized in the chemical processing industry? For Seals, Liners & Valves That Resist Corrosion

- What makes PTFE rotary shaft seals suitable for low friction or dry running applications? Unlock High-Speed, Dry-Running Performance

- Why don't PTFE O-rings swell? Discover the Key to Unmatched Chemical Stability