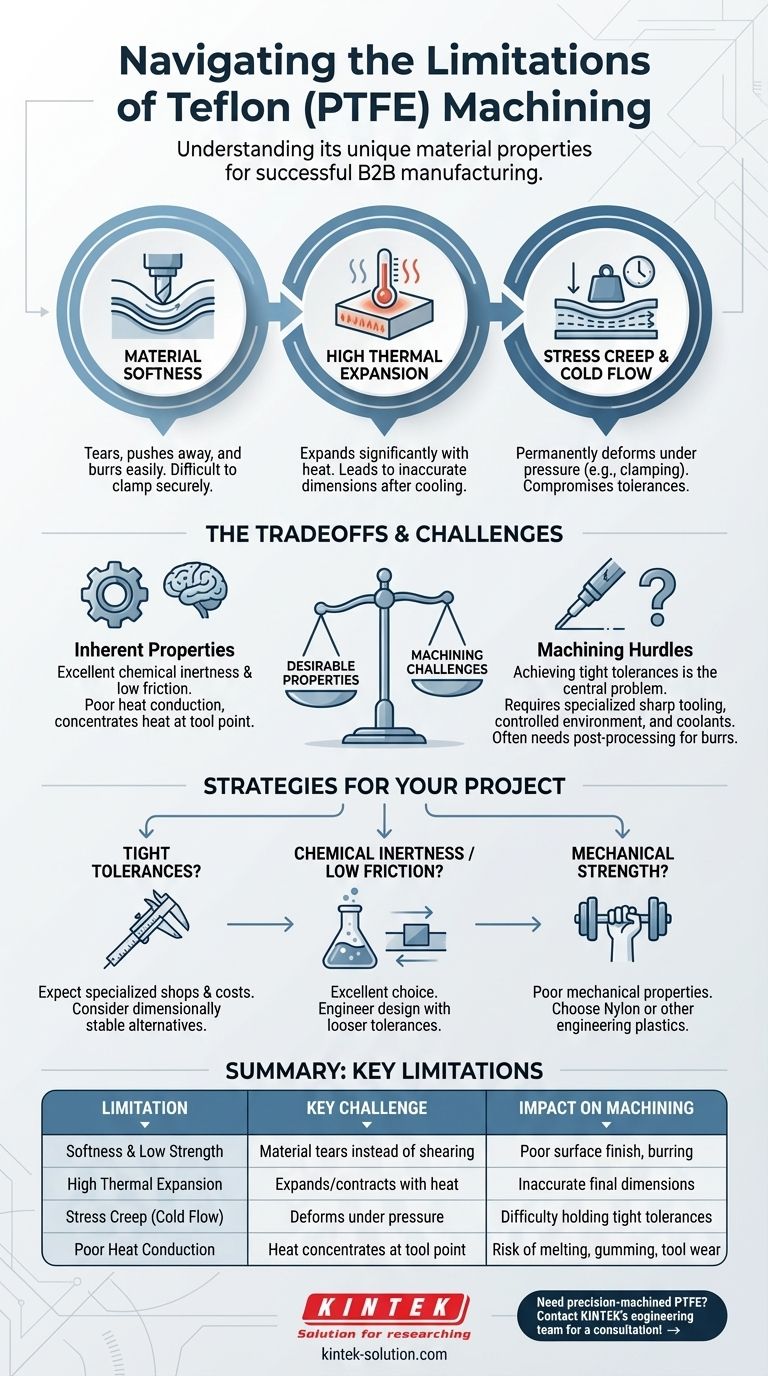

The primary limitations of machining Teflon (PTFE) are its material softness, its high coefficient of thermal expansion, and its tendency to deform under pressure, a phenomenon known as stress creep. These three properties combined make it uniquely challenging to achieve tight dimensional tolerances, manage heat during cutting, and prevent surface defects like burrs.

Teflon's greatest strengths—its chemical inertness and low friction—are a direct result of the same molecular properties that make it difficult to machine with high precision. The key to success is not fighting the material, but understanding and accommodating its unique behavior.

The Core Challenge: A Material of Contradictions

Teflon is often described as easy to machine because it is soft and cuts with little force. However, this softness is also the source of its greatest machining difficulties.

Softness and Low Strength

While a sharp tool moves through Teflon easily, the material's low strength means it often tears or pushes away from the blade rather than shearing cleanly. This can result in a poor surface finish and significant burring.

Furthermore, its softness makes secure clamping difficult. Too much pressure deforms the workpiece, while too little allows for vibration, which ruins the cut's accuracy.

High Thermal Expansion

Teflon expands and contracts with temperature changes far more than most materials. Even a small amount of heat generated during the machining process can cause the part to grow, leading to inaccurate final dimensions once it cools.

This requires a temperature-controlled environment and careful management of cutting speeds and feeds to minimize heat generation.

Stress Creep and Cold Flow

When put under mechanical stress, such as from clamping jaws or the pressure of a cutting tool, Teflon will slowly and permanently deform. This "cold flow" is a major reason why holding tight tolerances is so challenging.

The dimensions of a part can be compromised before a single cut is even made if it is clamped improperly.

Poor Heat Management

Teflon is an excellent thermal insulator, which means it doesn't conduct heat away from the cutting tool effectively. Heat concentrates at the point of contact, increasing the risk of material melting, gumming up the tool, and exacerbating the thermal expansion problem.

For this reason, non-aromatic, water-soluble coolants are often recommended to manage heat and improve tool life.

Understanding the Trade-offs

The decision to use Teflon must be weighed against the realities of its fabrication. Its desirable properties come with inherent manufacturing challenges.

The Difficulty of Tight Tolerances

The combination of thermal expansion, stress creep, and softness makes achieving high precision the central problem in Teflon machining. While possible, it requires specialized knowledge, tooling, and processes, which can increase costs.

The Risk of Burrs and Poor Finish

Due to its tendency to tear, Teflon parts often come off the machine with burrs that must be removed in a secondary operation. This post-processing step is frequently required to achieve a clean, finished part.

The Need for Specialized Tooling

Standard cutting tools are often inadequate for Teflon. Success requires extremely sharp cutting edges with specific geometries and narrow profiles to minimize cutting pressure and heat generation. In some cases, specialized diamond cutters are used for the best performance.

How to Apply This to Your Project

Understanding these limitations allows you to make informed decisions for your design and manufacturing process.

- If your primary focus is tight dimensional tolerance: Recognize that Teflon is an inherently difficult material for this and may require a specialized machine shop or consideration of a more dimensionally stable alternative.

- If your primary focus is chemical inertness or low friction: Teflon is an excellent choice, but your design must be engineered with looser tolerances to accommodate its material properties.

- If your primary focus is mechanical strength: Acknowledge that Teflon has poor mechanical properties and materials like Nylon or other engineering plastics are often a better fit.

Successfully leveraging Teflon is a matter of designing for its strengths while respecting its inherent machining limitations.

Summary Table:

| Limitation | Key Challenge | Impact on Machining |

|---|---|---|

| Softness & Low Strength | Material tears instead of shearing | Poor surface finish, significant burring |

| High Thermal Expansion | Expands/contracts with heat | Inaccurate final dimensions after cooling |

| Stress Creep (Cold Flow) | Deforms under pressure | Difficulty holding tight tolerances |

| Poor Heat Conduction | Heat concentrates at tool point | Risk of melting, gumming, tool wear |

Need Precision-Machined PTFE Components That Overcome These Challenges?

At KINTEK, we specialize in machining Teflon and other high-performance plastics for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique properties of PTFE and have the expertise and specialized tooling to manage softness, thermal expansion, and stress creep effectively.

We deliver the precision you require, from custom prototypes to high-volume production, ensuring your components meet exact specifications without compromising on the material's inherent benefits.

Let us put our expertise to work for your project. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials