At its core, a PTFE bush is also known as a PTFE lined bushing. While the names are often used interchangeably, the term "lined" can sometimes imply a composite structure where a PTFE layer is bonded to a stronger metal backing. However, in most general applications, both terms refer to the same type of component made from Polytetrafluoroethylene.

The specific name used for a PTFE bush is less important than understanding its core material properties. Whether you call it a "PTFE bush," "Teflon bushing," or "sleeve bearing," the critical factor is the performance delivered by the Polytetrafluoroethylene (PTFE) itself.

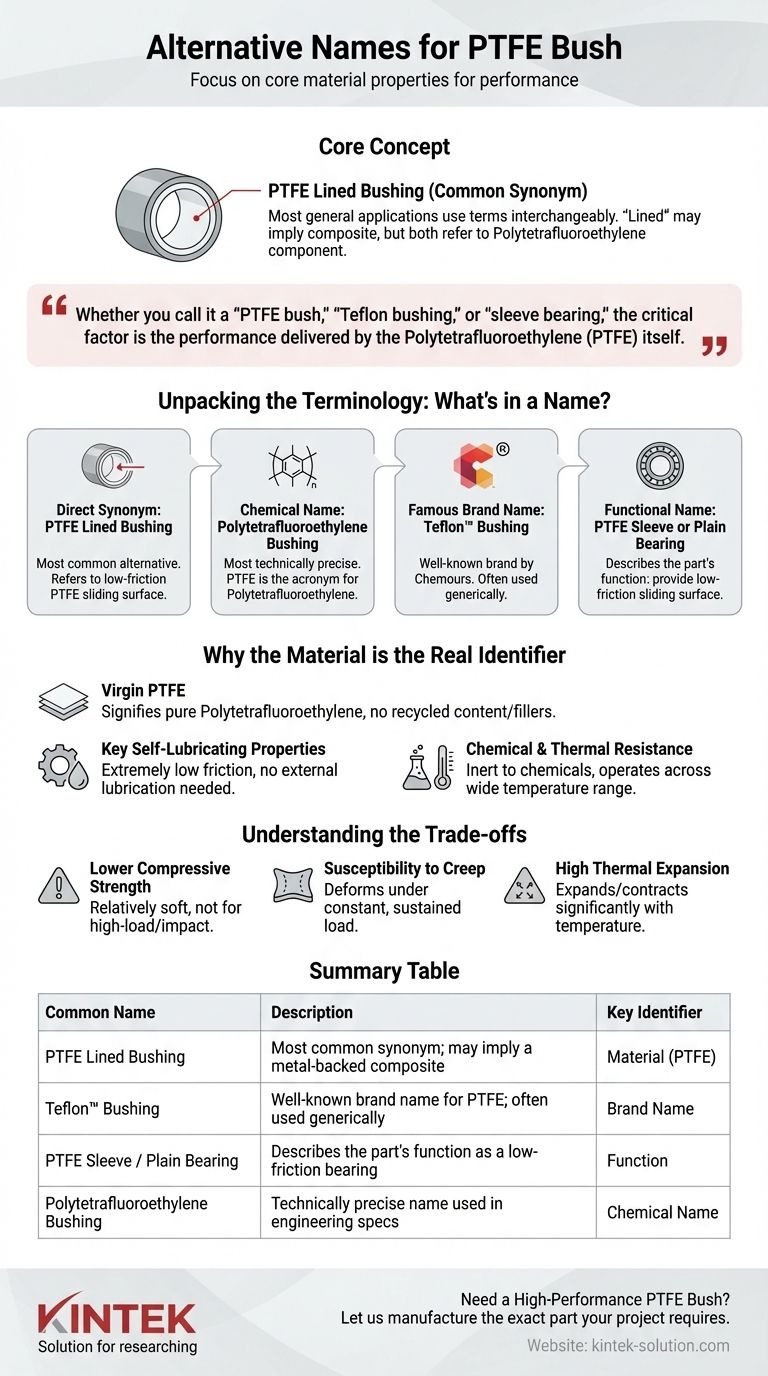

Unpacking the Terminology: What's in a Name?

To correctly source, specify, or replace this component, you must be familiar with all the terms used to describe it. These names often highlight the material, the brand, or the function of the part.

The Direct Synonym: PTFE Lined Bushing

This is the most common alternative name. It refers to a bushing where the critical sliding surface is made of PTFE, valued for its extremely low friction.

The Chemical Name: Polytetrafluoroethylene Bushing

This is the most technically precise name. PTFE is simply the acronym for the polymer Polytetrafluoroethylene. Using the full chemical name is common in technical data sheets and engineering specifications.

The Famous Brand Name: Teflon™ Bushing

Teflon™ is the well-known brand name for PTFE, originally created by DuPont and now owned by Chemours. Much like Kleenex for tissues, "Teflon" has become a generic term for PTFE in many industries.

The Functional Name: PTFE Sleeve or Plain Bearing

A "bush" or "bushing" is a type of plain bearing or sleeve bearing. These terms describe the part's function: to provide a low-friction sliding surface between two other components, typically a shaft and a housing.

Why the Material is the Real Identifier

The naming conventions all point to one thing: the unique properties of the material. When you specify a PTFE bush, you are selecting it for a specific set of performance characteristics.

The Core Material: Virgin PTFE

The references note that these bushings are made from virgin PTFE. This is a critical detail, signifying that the material is pure Polytetrafluoroethylene, without any recycled content or fillers. This ensures maximum performance and predictable properties.

Key Self-Lubricating Properties

The primary reason for using PTFE is its remarkably low coefficient of friction. It is one of the "slipperiest" materials known, allowing parts to move smoothly without external lubrication.

Chemical and Thermal Resistance

PTFE is highly inert, meaning it resists corrosion and degradation from nearly all industrial chemicals and solvents. It also operates effectively across a wide temperature range, a key advantage over many other plastics.

Understanding the Trade-offs

While powerful, PTFE is not the right choice for every application. Being aware of its limitations is crucial for successful engineering design.

Lower Compressive Strength

Compared to metal or even other engineering plastics, PTFE is relatively soft. It is not suitable for high-load or high-impact applications without reinforcement, such as a metal backing.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of precision assemblies.

High Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than metals. This requires careful consideration of clearances and tolerances to prevent parts from binding or becoming loose.

How to Specify the Correct Part

Choosing the right terminology depends entirely on your objective, whether you are buying, designing, or replacing a component.

- If your primary focus is sourcing and procurement: Use multiple search terms like "PTFE bush," "Teflon bushing," and "PTFE sleeve bearing" to broaden your results and find more suppliers.

- If your primary focus is technical specification: Use the most precise language. Specify a "Virgin Polytetrafluoroethylene (PTFE) plain bearing" and list the required dimensions and operating conditions.

- If your primary focus is replacing an existing part: Focus on measuring the inner diameter, outer diameter, and length. Note the operating environment (load, speed, temperature) to ensure the replacement part meets the same performance demands.

Ultimately, knowing the different names for a PTFE bush empowers you to communicate your needs clearly and accurately.

Summary Table:

| Common Name | Description | Key Identifier |

|---|---|---|

| PTFE Lined Bushing | Most common synonym; may imply a metal-backed composite. | Material (PTFE) |

| Teflon™ Bushing | Well-known brand name for PTFE; often used generically. | Brand Name |

| PTFE Sleeve / Plain Bearing | Describes the part's function as a low-friction bearing. | Function |

| Polytetrafluoroethylene Bushing | Technically precise name used in engineering specs. | Chemical Name |

Need a High-Performance PTFE Bush?

Understanding the terminology is the first step. Sourcing a precision-manufactured component made from virgin PTFE is what ensures your application's success. KINTEK specializes in the custom fabrication of PTFE components—including seals, liners, labware, and bushings—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver the critical advantages of PTFE:

- Superior Self-Lubrication for low friction and minimal wear.

- Exceptional Chemical & Thermal Resistance for harsh environments.

- Precision Production from prototypes to high-volume orders.

Let us manufacture the exact PTFE bush your project requires. Contact our team today for a quote or to discuss your specifications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What material was considered as an alternative to Turcite for making fork bushes, and why? Uncover the PTFE vs. Acetal Trade-off

- What key offerings are associated with Teflon-encapsulated O-Rings? Beyond the Part to Full-System Support

- How do PTFE slide bearings accommodate thermal and seismic movements? Control Structural Movement with Low-Friction Design

- Why is PTFE commonly used as a sealing material? Superior Chemical & Temperature Resistance

- What are dynamic applications and why are PTFE O-Rings suitable for them? Unlock Low-Friction, Chemical-Resistant Sealing

- What are the primary functions of PTFE expansion bellows? Absorb Movement, Dampen Vibration, and Protect Pipes

- What are the performance characteristics of PTFE spacers? Unlock Superior Sealing for Demanding Industries

- How can designers balance aesthetics and functionality in PTFE machining? Master Material Properties for Superior Results