To balance aesthetics and functionality in PTFE machining, you must design with the material's unique properties, not against them. This involves specifying machining parameters that manage its inherent softness and high thermal expansion, ensuring that the techniques used for functional accuracy simultaneously produce a superior surface finish. Success depends on a deep understanding of the material and close collaboration between design and engineering teams.

The core challenge with PTFE is that the very properties that make it functionally unique—its softness and high thermal expansion—are also the primary obstacles to achieving a clean, aesthetically pleasing finish. The solution lies in precise control over heat generation and mechanical stress during the machining process.

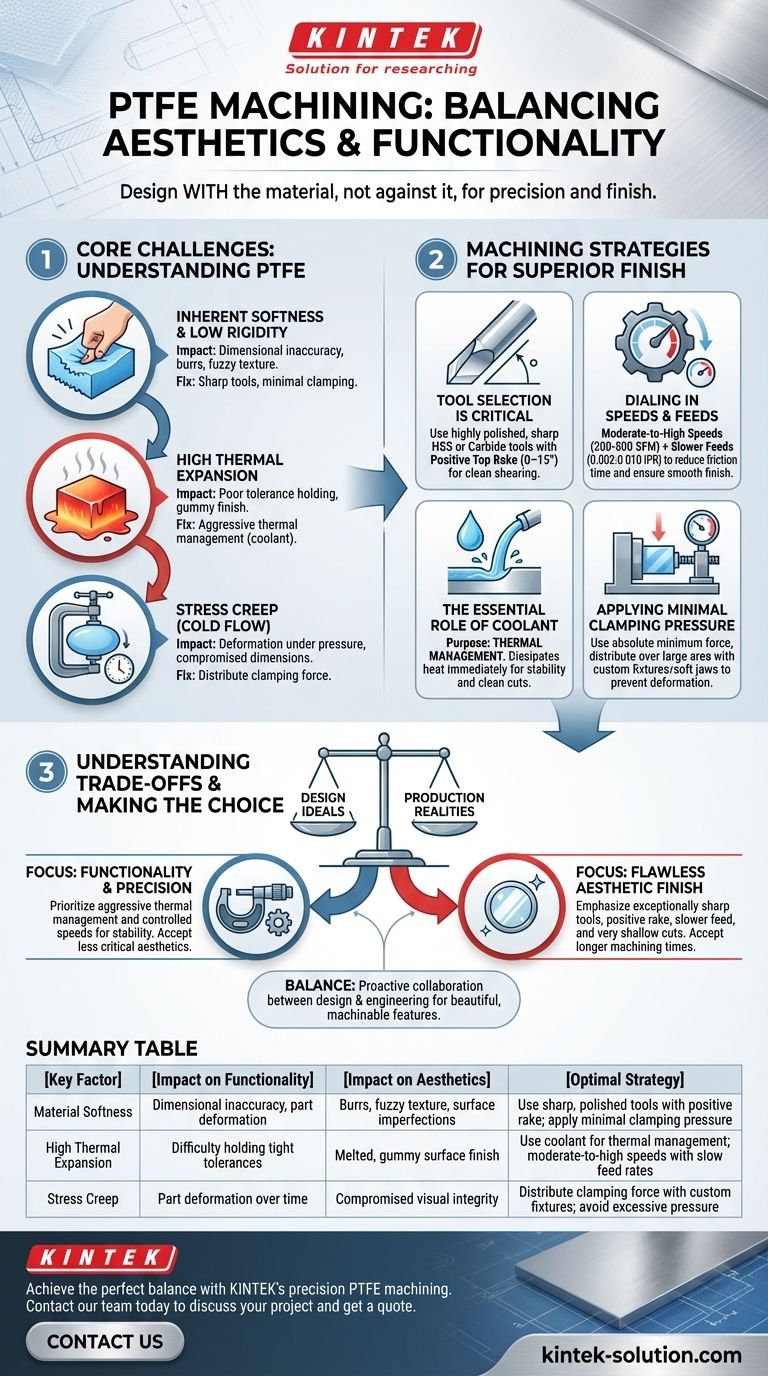

Understanding PTFE's Core Machining Challenges

To achieve a balance between look and performance, you must first understand the properties that make PTFE (Polytetrafluoroethylene) notoriously difficult to machine to a high standard.

Its Inherent Softness and Low Rigidity

PTFE is an exceptionally soft material. While this makes it easy to cut, it also means the material can easily compress, deform, or tear under pressure.

This directly impacts functionality through dimensional inaccuracy and affects aesthetics by causing surface imperfections like burrs or a "fuzzy" texture.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Heat generated from tool friction during cutting causes the material to expand significantly.

As it cools, it contracts, making it incredibly difficult to hold tight tolerances (a functional requirement). This heat can also cause the material to become gummy, leading to a poor, melted-looking surface finish (an aesthetic failure).

Stress Creep

When subjected to clamping pressure in a machining setup, PTFE can slowly deform over time, a property known as stress creep or "cold flow."

This can cause the part to be machined out of spec before a single cut is made, compromising both its final dimensions and its visual integrity.

Machining Strategies for a Superior Finish

Achieving a part that is both dimensionally accurate and visually clean requires specific strategies to counteract PTFE's natural tendencies.

Tool Selection is Critical

The cutting tool is the single most important factor for surface finish. Use extremely sharp and polished cutting tools, preferably made from high-speed steel (HSS) or carbide.

Tools with a positive top rake (0–15 degrees) are ideal as they create a shearing action that cuts cleanly rather than pushing or tearing the material. Regular resharpening is non-negotiable.

Dialing in Speeds and Feeds

Managing heat is the primary goal. The consensus is to use moderate-to-high cutting speeds (200-500 surface feet per minute, or SFM) combined with slower feed rates (0.002-0.010 inches per revolution).

This combination allows the tool to cut efficiently while minimizing friction time, and the slow feed ensures a smoother finish. A shallow depth of cut also helps reduce cutting forces and heat.

The Essential Role of Coolant

Using a generous amount of coolant or lubricant is crucial. Its primary purpose is not lubrication but thermal management.

Coolant immediately dissipates the heat generated at the cutting edge, preventing the PTFE from expanding and ensuring dimensional stability and a clean, sharp cut.

Applying Minimal Clamping Pressure

To avoid part deformation due to softness and stress creep, use the absolute minimum clamping pressure required to hold the workpiece securely.

Distributing the clamping force over a larger surface area with custom fixtures or soft jaws can prevent marring the surface and compressing the material.

Understanding the Trade-offs

Working with PTFE involves accepting certain limitations and making informed compromises between design ideals and production realities.

Chasing Unrealistic Tolerances

Due to its high thermal expansion and softness, PTFE is not the right material for applications requiring the same tight tolerances as metals or more rigid polymers. Attempting to hold excessively tight dimensions often leads to high scrap rates and functional failure.

Sacrificing Speed for Finish

Achieving a truly premium aesthetic finish often requires slower feed rates and shallower cuts. This increases machining time and cost. The project must balance the need for visual perfection with budget and timeline constraints.

Ignoring Material Safety

The micro-dust produced when machining PTFE can be hazardous if inhaled. Always ensure proper ventilation, wear a mask, or machine the material under a steady flow of coolant to suppress dust. Functionality and aesthetics are irrelevant if safety is compromised.

Making the Right Choice for Your Goal

Your primary objective should dictate your approach, blending design intent with machining best practices from the start.

- If your primary focus is functionality and precision: Prioritize aggressive thermal management with constant coolant flow and carefully controlled speeds to maintain dimensional stability above all else.

- If your primary focus is a flawless aesthetic finish: Emphasize using exceptionally sharp, polished tools with a positive rake, slower feed rates, and very shallow final cuts to achieve a smooth surface.

- If your primary focus is a true balance: The key is proactive collaboration. Designers must create features that are friendly to PTFE's nature (e.g., avoiding knife-edges), and engineers must provide feedback to achieve a design that is both beautiful and machinable.

Ultimately, mastering PTFE is about respecting the material and using precision techniques to guide it to the desired form.

Summary Table:

| Key Factor | Impact on Functionality | Impact on Aesthetics | Optimal Strategy |

|---|---|---|---|

| Material Softness | Dimensional inaccuracy, part deformation | Burrs, fuzzy texture, surface imperfections | Use sharp, polished tools with positive rake; apply minimal clamping pressure |

| High Thermal Expansion | Difficulty holding tight tolerances | Melted, gummy surface finish | Use coolant for thermal management; moderate-to-high speeds with slow feed rates |

| Stress Creep | Part deformation over time | Compromised visual integrity | Distribute clamping force with custom fixtures; avoid excessive pressure |

Achieve the perfect balance of form and function in your PTFE components. At KINTEK, we specialize in precision PTFE machining for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing material properties like softness and thermal expansion ensures your parts meet stringent functional requirements while maintaining a superior aesthetic finish. Whether you need custom prototypes or high-volume production, we deliver solutions tailored to your unique challenges. Contact our team today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability