In short, dynamic applications are any system where a seal is required between moving parts. PTFE O-rings are frequently specified for these demanding roles due to their exceptionally low friction, resistance to corrosive chemicals, and ability to handle extreme temperatures. This makes them highly effective in components like rotating pump shafts, moving valve stems, and swiveling joints where standard rubber seals would quickly fail.

While common elastomers degrade under harsh conditions, PTFE O-rings thrive in dynamic applications involving aggressive chemicals, high pressures, and wide temperature ranges. Their success, however, hinges on understanding the material's unique properties and selecting a design that accounts for its inherent rigidity.

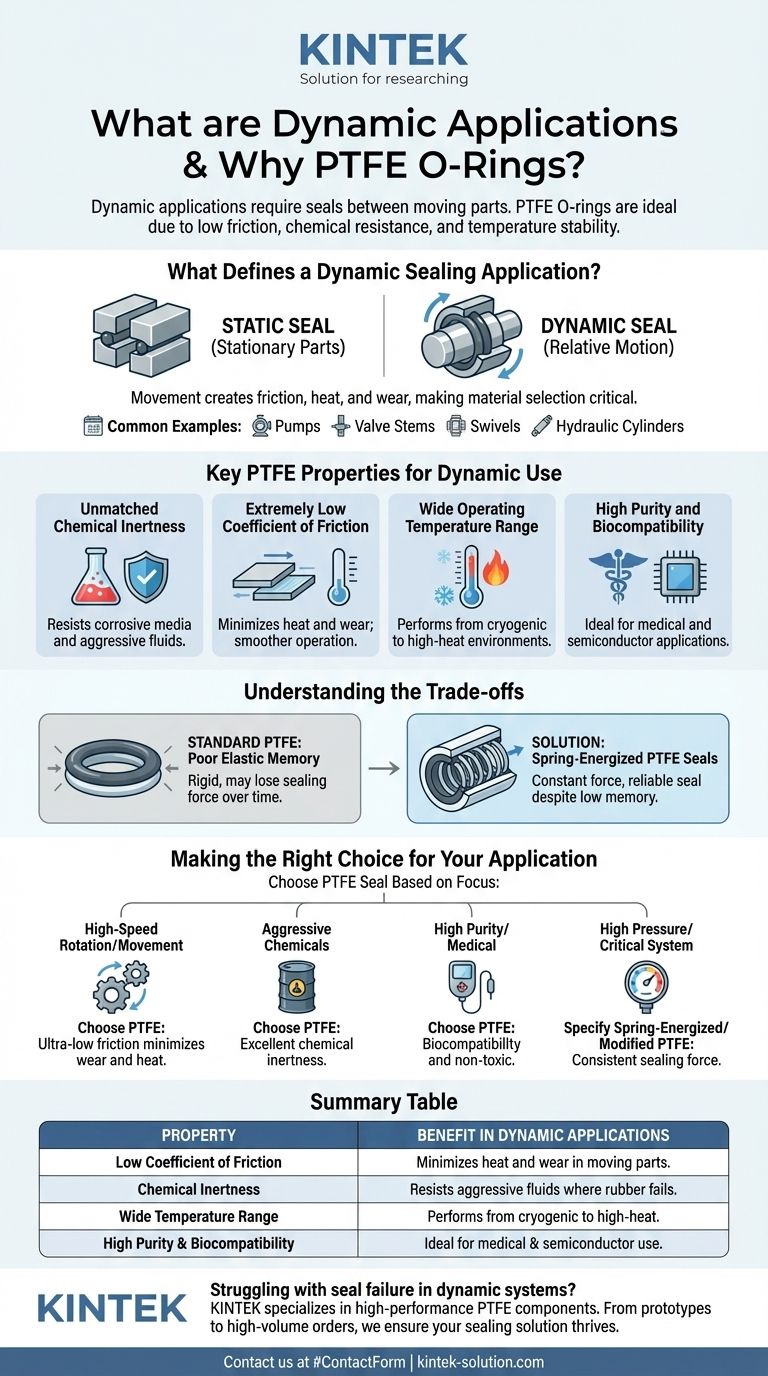

What Defines a Dynamic Sealing Application?

A dynamic seal prevents leakage between components that are in relative motion. This movement is the key factor that distinguishes it from a static seal, which sits between two stationary parts.

The Core Concept: Relative Motion

The central challenge in any dynamic application is maintaining a seal despite constant movement. This motion can be rotational (a spinning shaft), reciprocating (a piston moving back and forth), or oscillating.

The Challenge: Friction and Wear

This continuous movement generates friction, which in turn creates heat and causes wear. These three factors are the primary causes of failure for seals in dynamic systems, making material selection absolutely critical.

Common Examples in Industry

You will find dynamic seals in countless industrial components. Common examples include pumps, valve stems, swivels, and hydraulic cylinders, all of which rely on a seal to function without leaking while parts are in motion.

Key PTFE Properties for Dynamic Use

Polytetrafluoroethylene (PTFE) is not an elastomer like rubber; it is a fluoropolymer with a distinct set of properties that make it uniquely suited for difficult dynamic applications.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack, making it the default choice for sealing aggressive fluids and corrosive media that would destroy conventional seal materials.

Extremely Low Coefficient of Friction

This is perhaps PTFE's most important feature for dynamic use. Its surface is incredibly slick, minimizing friction against moving parts. This reduces heat generation, lowers wear on the seal and the equipment, and allows for smoother operation.

Wide Operating Temperature Range

PTFE maintains its integrity and performance across a vast range of temperatures, from cryogenic lows to high-heat environments where other plastics and rubbers would become brittle or melt.

High Purity and Biocompatibility

Because PTFE is inert and non-toxic, it is a preferred material for applications where purity is essential. This includes medical devices like catheters and syringes, as well as equipment used in semiconductor manufacturing.

Understanding the Trade-offs

While its properties are impressive, it's crucial to understand that standard PTFE is not a simple drop-in replacement for a rubber O-ring. Its suitability can be a point of confusion.

The Contradiction: Static vs. Dynamic

Some sources state that PTFE is mainly for static applications. This is because standard, unfilled PTFE is a relatively rigid material compared to a flexible elastomer.

The Challenge of Material "Memory"

Unlike rubber, PTFE has poor elastic memory. It does not spring back into its original shape as effectively after being compressed. In a dynamic application, this can lead to a loss of sealing force over time if not properly accounted for in the design.

The Solution: Modified and Energized Seals

This limitation is overcome in two ways. First, PTFE can be blended with fillers to improve its mechanical properties. More commonly for demanding dynamic roles, engineers use spring-energized PTFE seals. These designs incorporate a metal spring inside a PTFE jacket, providing constant force to ensure a reliable seal despite the material's low memory.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's strengths to the application's primary demand.

- If your primary focus is high-speed rotation or frequent movement: Choose PTFE for its ultra-low friction, which will minimize wear and heat buildup on your components.

- If your primary focus is sealing aggressive chemicals: PTFE's chemical inertness makes it one of the few viable options where other materials would rapidly degrade.

- If your primary focus is a high-purity or medical application: PTFE's biocompatibility and non-toxic nature make it a safe and reliable choice.

- If your primary focus is a high-pressure or critical dynamic system: Specify a spring-energized or modified PTFE seal to ensure consistent sealing force and overcome the material's natural rigidity.

By understanding PTFE's unique balance of properties and design considerations, you can confidently specify the right sealing solution for the most demanding dynamic systems.

Summary Table:

| Property | Benefit in Dynamic Applications |

|---|---|

| Low Coefficient of Friction | Minimizes heat and wear in moving parts like pump shafts and valve stems. |

| Chemical Inertness | Resists aggressive fluids and corrosive media where rubber seals fail. |

| Wide Temperature Range | Performs from cryogenic to high-heat environments. |

| High Purity & Biocompatibility | Ideal for medical devices and semiconductor manufacturing. |

Struggling with seal failure in demanding dynamic systems? KINTEK specializes in manufacturing high-performance PTFE components, including custom O-rings, seals, liners, and labware. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that thrives under motion, chemical exposure, and extreme temperatures. Contact us today at #ContactForm to discuss how our PTFE seals can enhance your application's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers