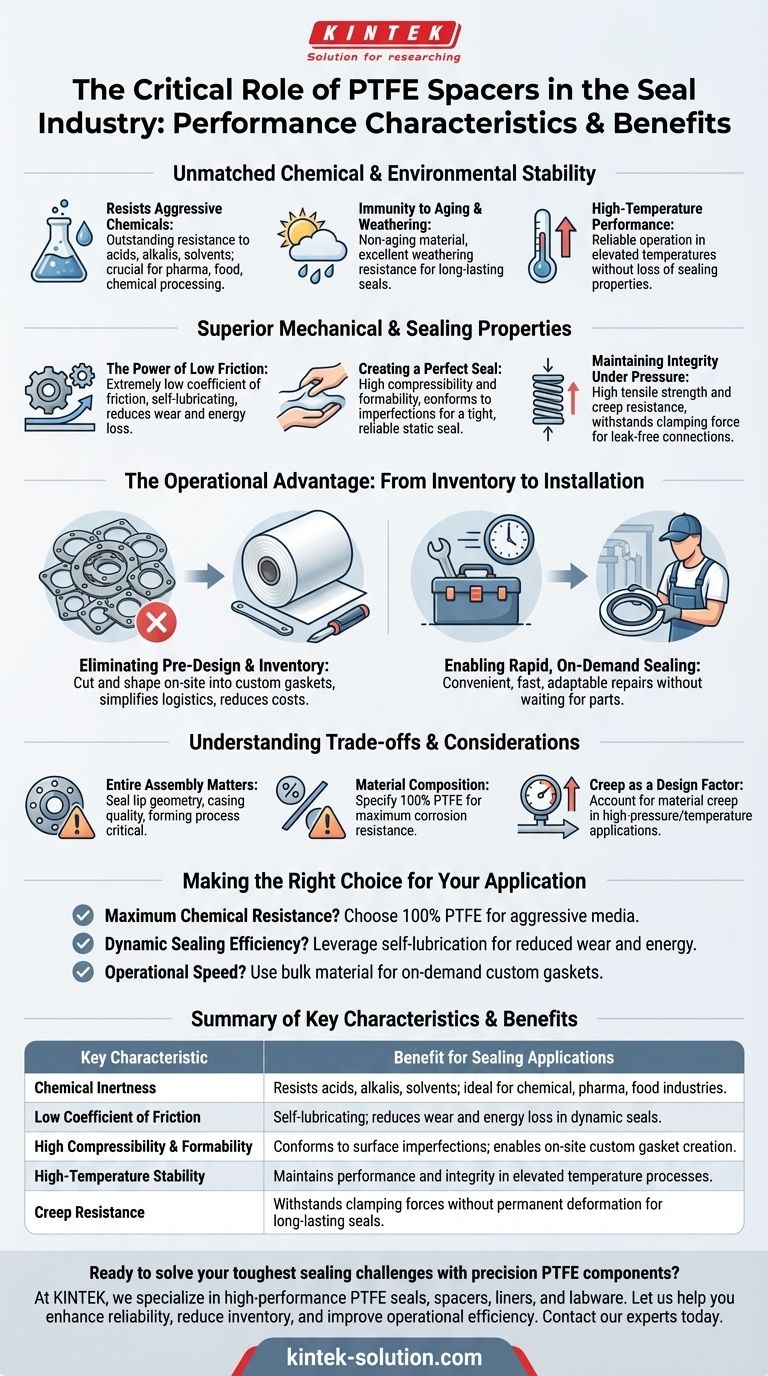

In the seal industry, PTFE spacers are critical components prized for a unique combination of chemical, mechanical, and operational characteristics. Their value comes from their extreme chemical inertness, exceptionally low coefficient of friction, and remarkable formability, which together solve complex sealing challenges in demanding environments.

The true importance of PTFE is not just its material properties, but how these properties fundamentally change sealing operations. PTFE’s ability to be formed on-site into custom gaskets eliminates the need for large inventories of pre-sized seals, increasing efficiency and adaptability.

Unmatched Chemical and Environmental Stability

The primary function of a seal is to create a barrier. PTFE excels in this role because it remains stable and effective in environments where many other materials would quickly fail.

Resisting Aggressive Chemicals

PTFE offers outstanding resistance to acids, alkalis, and other corrosive chemicals. This inertness ensures that the seal maintains its integrity and does not contaminate the system it is protecting, which is critical in chemical processing, pharmaceutical, and food industries.

Immunity to Aging and Weathering

Unlike many polymers that degrade over time with exposure to UV light or atmospheric conditions, PTFE is a non-aging material with excellent weathering resistance. This translates to a longer, more reliable service life for seals, especially in outdoor or exposed applications.

High-Temperature Performance

PTFE spacers and seals perform reliably at elevated temperatures. This thermal stability allows them to be used in high-temperature processes without losing their critical sealing properties.

Superior Mechanical and Sealing Properties

Beyond its resilience, PTFE's physical characteristics are what make it a uniquely effective sealing material. These properties ensure a tight, durable, and low-maintenance seal.

The Power of Low Friction

PTFE has an extremely low coefficient of friction and is self-lubricating. In dynamic sealing applications, this means less energy is lost to friction, component wear is significantly reduced, and the risk of stick-slip motion is minimized.

Creating a Perfect Seal

The material is described as being soft, formable, and having high compressibility, much like cotton. This flexibility allows it to conform perfectly to surface imperfections in flanges and housings, creating a highly effective and reliable static seal.

Maintaining Integrity Under Pressure

Despite its softness, PTFE possesses both high tensile strength and creep resistance. This means it can withstand significant clamping force without being permanently deformed or "creeping" out of the joint over time, ensuring a long-lasting, leak-free connection.

The Operational Advantage: From Inventory to Installation

The combination of PTFE's properties has transformed not just the seal itself, but the entire workflow associated with industrial sealing.

Eliminating Pre-Design and Inventory

Because PTFE material is so formable, it can be cut and shaped on-site into gaskets and fillings of any diameter or cross-section. This nearly eliminates the need to pre-design and stock a vast inventory of specific seal sizes, drastically simplifying logistics and reducing costs.

Enabling Rapid, On-Demand Sealing

The ability to create custom seals on demand makes maintenance and repair operations convenient, fast, and adaptable. Technicians can respond to needs as they arise without waiting for pre-manufactured parts to be delivered.

Understanding the Trade-offs and Considerations

While PTFE is a superior material, its optimal performance depends on proper system design and application awareness.

The Importance of the Entire Assembly

The reliability of a PTFE seal often depends on the components around it. Factors like the seal lip geometry, the quality of the steel casing, and the precision of the forming process are all critical. The seal is part of a system, and the PTFE's properties must be supported by correct engineering.

Material Composition Matters

For applications requiring the highest level of corrosion resistance, a 100% PTFE option is available. Standard seals may incorporate other materials, such as mild steel or stainless steel casings, which may not be suitable for every chemical environment. It is crucial to specify the right composition for the application.

Creep as a Design Factor

While PTFE has good creep resistance for a polymer, it is not immune. In high-pressure and high-temperature applications, the potential for material creep must be factored into the joint design to ensure the seal maintains its clamping load over its entire service life.

Making the Right Choice for Your Application

Selecting and implementing PTFE spacers effectively requires aligning their strengths with your primary goal.

- If your primary focus is maximum chemical resistance: Specify a 100% PTFE component or an assembly where all wetted parts are PTFE to prevent corrosion in aggressive media.

- If your primary focus is dynamic sealing efficiency: Leverage PTFE's self-lubrication and low friction to design systems that minimize wear, reduce energy consumption, and operate smoothly.

- If your primary focus is operational speed and inventory reduction: Equip your teams with bulk PTFE material and the tools to create custom gaskets on-demand, transforming your maintenance strategy.

Ultimately, PTFE's unique combination of properties makes it a foundational material for modern, high-performance sealing solutions.

Summary Table:

| Key Characteristic | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists acids, alkalis, and solvents; ideal for chemical processing, pharma, and food industries. |

| Low Coefficient of Friction | Self-lubricating; reduces wear and energy loss in dynamic seals. |

| High Compressibility & Formability | Conforms to surface imperfections for a perfect static seal; enables on-site custom gasket creation. |

| High-Temperature Stability | Maintains performance and integrity in elevated temperature processes. |

| Creep Resistance | Withstands clamping forces without permanent deformation for long-lasting seals. |

Ready to solve your toughest sealing challenges with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, spacers, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly tailored to your application's chemical, thermal, and mechanical demands.

Let us help you enhance reliability, reduce inventory, and improve operational efficiency.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance