At their core, Polytetrafluoroethylene (PTFE) slide bearings accommodate structural movements by creating a low-friction sliding surface. This interface allows components of a structure, like a bridge deck or a large roof, to move independently of their supports, safely dissipating energy from thermal expansion or seismic events without transferring damaging stress into the primary frame.

The fundamental principle behind a PTFE slide bearing is not to resist movement, but to control it. By providing a predictable, low-friction plane, it decouples the structure from its foundation, allowing it to safely slide and dissipate energy that would otherwise cause damage.

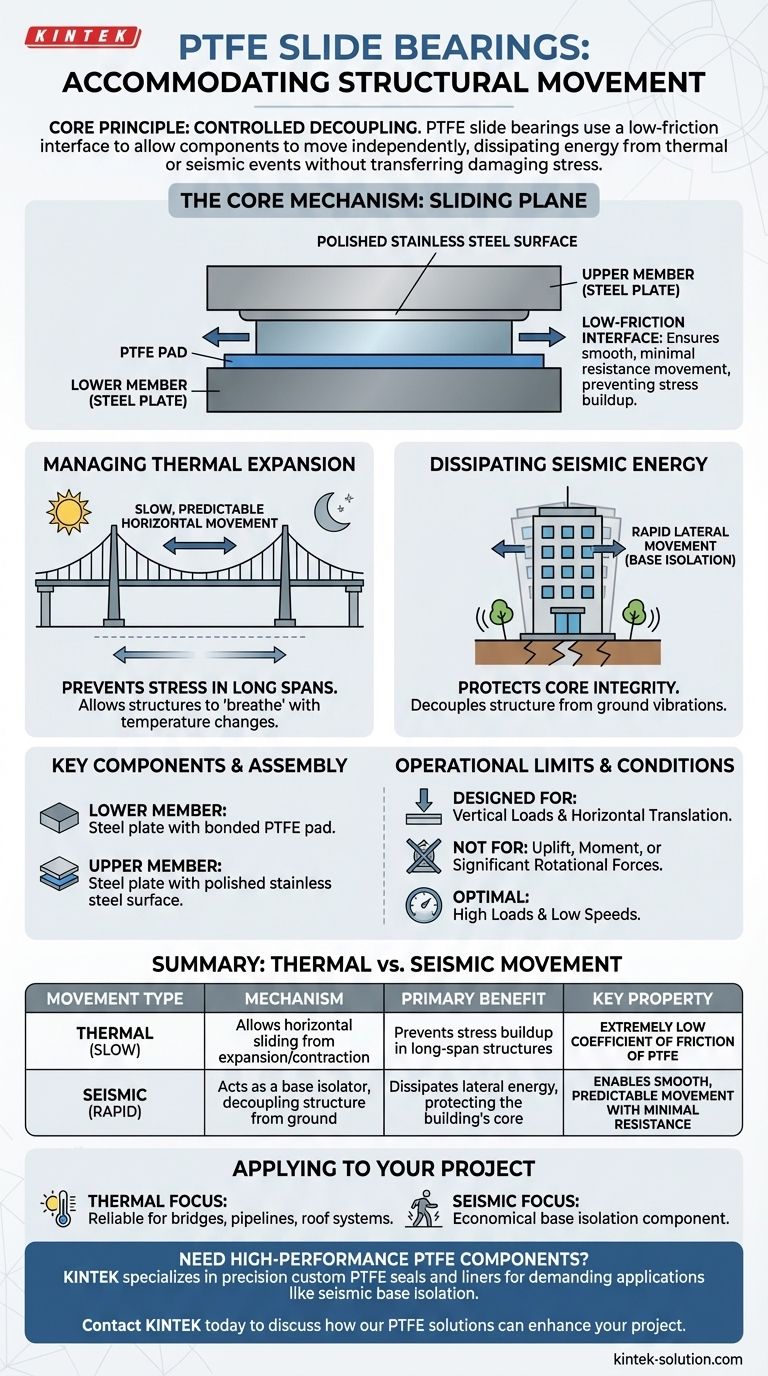

The Core Mechanism: Controlled Decoupling

PTFE slide bearings are a simple yet highly effective engineering solution. Their function relies on the unique properties of PTFE and a specific assembly of components.

How the Sliding Plane Works

The bearing consists of two primary steel plates that face each other. One plate is bonded with a sheet of PTFE, while the mating plate features a highly polished stainless steel surface.

When movement occurs—whether slow thermal expansion or rapid seismic shaking—the PTFE surface slides against the stainless steel.

The Critical Role of Low Friction

PTFE is known for having one of the lowest coefficients of friction of any solid material. This self-lubricating property is essential.

It ensures that the structure can move smoothly and with minimal resistance. This prevents the buildup of stress that could otherwise crack concrete, buckle steel, or compromise structural joints.

Key Components and Assembly

A typical PTFE slide bearing has two main parts. The lower member features a steel plate with the PTFE pad bonded to it.

The upper member is a steel plate with a polished stainless steel surface facing downward. This orientation is critical for performance and preventing contamination of the sliding surfaces.

Managing Thermal vs. Seismic Forces

While the sliding mechanism is the same, how it protects against thermal and seismic forces differs based on the speed and nature of the movement.

Accommodating Thermal Expansion and Contraction

Materials like steel and concrete expand and contract with temperature changes. Over a long bridge span, this movement can be significant.

PTFE bearings allow for this slow, predictable horizontal movement. They let the bridge deck "breathe" throughout the day and across seasons, preventing immense internal stresses.

Dissipating Seismic Energy

During an earthquake, the ground shakes violently. A conventional, rigid connection would transfer this entire force directly into the building, causing catastrophic failure.

A PTFE slide bearing acts as a base isolation system. It allows the ground to move underneath the structure while the building itself remains more stable, dissipating the lateral energy through the friction of the sliding motion.

Understanding the Operational Limits

While highly effective, PTFE slide bearings are not a universal solution. Their design imposes specific limitations that are critical to understand.

Designed for Vertical Loads and Horizontal Translation

A standard PTFE slide bearing is engineered to do two things: support immense vertical weight and allow for horizontal movement.

They are not designed to resist uplift, moment, or significant rotational forces unless incorporated into a more complex assembly. Their primary function is to support gravity loads while permitting sliding.

Optimal Performance Conditions

These bearings perform best under high loads and at low speeds. The high load ensures consistent, uniform contact between the PTFE and stainless steel surfaces.

The low-speed movement, characteristic of thermal cycles and seismic shifts, is where their low-friction properties are most effective. They are not intended for continuous, high-speed dynamic applications.

How to Apply This to Your Project

The decision to use a PTFE slide bearing depends entirely on the type of movement you need to manage.

- If your primary focus is thermal movement: These bearings offer a simple, reliable way to prevent stress buildup in long-span structures like bridges, pipelines, or large roof systems.

- If your primary focus is seismic protection: They serve as an effective and economical base isolation component, decoupling a building from ground vibrations to preserve its core integrity.

Ultimately, specifying a PTFE slide bearing is about choosing to manage structural forces through controlled movement rather than rigid resistance.

Summary Table:

| Movement Type | Mechanism | Primary Benefit |

|---|---|---|

| Thermal (Slow) | Allows horizontal sliding from expansion/contraction | Prevents stress buildup in long-span structures |

| Seismic (Rapid) | Acts as a base isolator, decoupling structure from ground motion | Dissipates lateral energy, protecting the building's core |

| Key Property | Extremely low coefficient of friction of PTFE | Enables smooth, predictable movement with minimal resistance |

Need high-performance PTFE components for your structural bearing or industrial application?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, and components. Our expertise ensures the material properties critical for reliable, low-friction performance in demanding environments like seismic base isolation systems and large-scale construction.

We serve the semiconductor, medical, laboratory, and specialized industrial sectors with prototypes and high-volume orders.

Contact KINTEB today to discuss how our PTFE solutions can enhance the safety and durability of your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments