At their core, Teflon-coated bolts are engineered for superior reliability in harsh conditions. Their primary advantages are exceptional corrosion resistance, a uniquely low coefficient of friction that ensures predictable tightening, and non-stick properties that prevent seizure during removal. These characteristics make them a premier choice for demanding industrial, marine, and chemical applications.

The true value of a Teflon coating on a fastener is not just surface protection. It is about solving two fundamental engineering problems: achieving a precise clamping force upon installation and guaranteeing easy disassembly for maintenance, even after long-term exposure to corrosive elements.

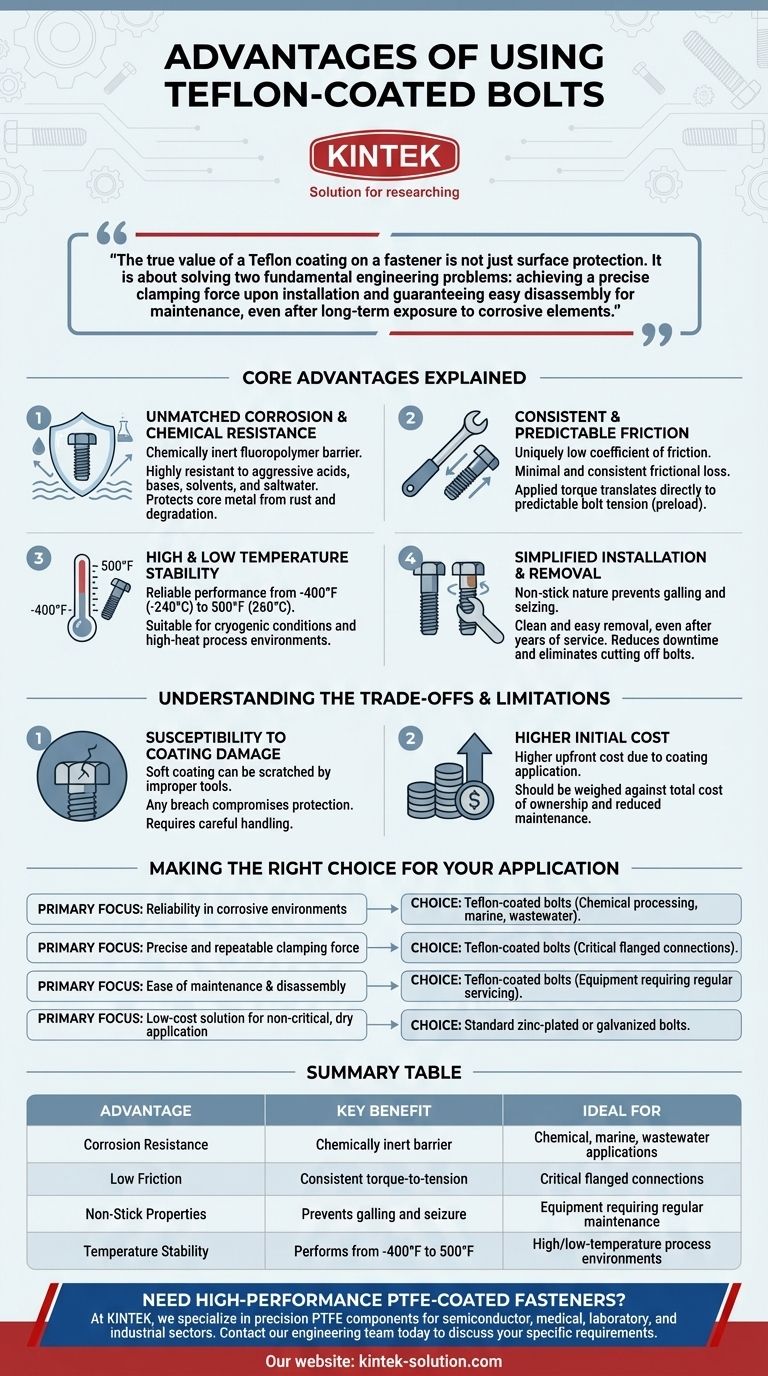

The Core Advantages Explained

The benefits of using a Teflon (PTFE) coating go far beyond a simple protective layer. Each property solves a specific, often critical, challenge faced in mechanical assemblies.

Unmatched Corrosion and Chemical Resistance

Teflon is a fluoropolymer that is almost completely chemically inert. This means it is highly resistant to a vast range of substances, including aggressive acids, bases, solvents, and saltwater.

This inertness acts as an impenetrable barrier, protecting the bolt's core metal from rust and chemical attack that would otherwise degrade its structural integrity.

Consistent and Predictable Friction

This is perhaps the most significant, yet often misunderstood, advantage. A significant portion of the torque applied to a standard bolt is lost to overcoming friction in the threads and under the head.

Because Teflon has one of the lowest coefficients of friction of any solid material, this frictional loss is minimal and, more importantly, consistent from bolt to bolt. This allows the applied torque to translate directly and predictably into bolt tension (or preload), ensuring a secure and evenly compressed joint.

High and Low Temperature Stability

Teflon-coated fasteners perform reliably across a wide operational temperature range. They can withstand continuous service temperatures up to approximately 500°F (260°C) and remain effective in cryogenic conditions as low as -400°F (-240°C).

This stability makes them suitable for applications involving hot process fluids, steam lines, or equipment exposed to extreme environmental temperature swings.

Simplified Installation and Removal

The non-stick nature of Teflon prevents galling, a common problem where fastener threads seize together under pressure, especially with stainless steel. This makes removal for maintenance or inspection clean and easy, even after years of service.

This property significantly reduces downtime, eliminates the need to cut off seized bolts, and often allows the fasteners to be reused, offsetting their initial cost.

Understanding the Trade-offs and Limitations

While highly effective, Teflon-coated bolts are not a universal solution. Acknowledging their limitations is key to using them correctly.

Susceptibility to Coating Damage

The Teflon coating provides the protection, but it is still a relatively soft layer. Using improper tools, like impact wrenches with poorly fitting sockets, can scratch or chip the coating.

Any breach in the coating becomes a potential site for corrosion to begin, compromising the fastener's primary defense. Careful handling and proper installation techniques are essential.

Higher Initial Cost

Specialty-coated fasteners have a higher upfront cost compared to standard zinc-plated or galvanized bolts. The process of surface preparation and coating application adds to the manufacturing expense.

However, this cost should be weighed against the total cost of ownership, including reduced maintenance, prevention of equipment failure, and increased service life.

Defined Temperature Ceilings

While the 500°F (260°C) service temperature is high, it is an absolute limit. For applications involving extreme heat, such as engine exhaust components or high-temperature furnaces, fasteners made from nickel alloys or other exotic materials are necessary.

Making the Right Choice for Your Application

Use your primary engineering goal to determine if Teflon-coated bolts are the appropriate choice.

- If your primary focus is reliability in corrosive environments: Teflon-coated bolts are the definitive choice for chemical processing, offshore platforms, and wastewater treatment plants.

- If your primary focus is precise and repeatable clamping force: The low, consistent friction makes these bolts ideal for critical flanged connections where even gasket compression is paramount.

- If your primary focus is ease of maintenance and disassembly: The anti-galling and non-stick properties are invaluable for equipment that requires regular servicing, preventing costly bolt removal issues.

- If your primary focus is a low-cost solution for a non-critical, dry application: A standard zinc-plated or hot-dip galvanized bolt will likely provide sufficient performance more economically.

Ultimately, selecting a Teflon-coated bolt is an engineering decision to prioritize long-term reliability and performance over initial component cost.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Corrosion Resistance | Chemically inert barrier against acids, bases, and saltwater | Chemical processing, marine, and wastewater applications |

| Low Friction | Consistent torque-to-tension for precise clamping force | Critical flanged connections and assemblies |

| Non-Stick Properties | Prevents galling and seizure for easy disassembly | Equipment requiring regular maintenance |

| Temperature Stability | Performs from -400°F to 500°F (-240°C to 260°C) | High/low-temperature process environments |

Need high-performance PTFE-coated fasteners for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-coated bolts, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get reliable, corrosion-resistant fasteners that deliver predictable performance and simplify maintenance—from prototype to high-volume production.

Contact our engineering team today to discuss your specific requirements and get a custom solution that enhances your assembly's reliability and lifespan.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is PTFE and what makes it suitable for gaskets? The Ultimate Guide to High-Performance Sealing

- What are some specific uses of PTFE in chemical handling? Enhance Safety and Reliability in Your Process

- What temperature range can PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- How does the chemical resistance of custom Teflon rotary shaft seals benefit industrial applications? Ensure Unmatched Reliability in Harsh Environments

- What are the automotive applications of Teflon coating? Boost Performance and Durability

- Are Teflon parts capable of withstanding high temperatures? Understanding the 260°C Limit for Performance

- Why is PTFE preferred in CNC machining for product design? Unlock High-Performance Components

- What are the potential issues of not using a Teflon sheet with a heat press? Protect Your Equipment & Projects