Operating a heat press without a Teflon sheet exposes your equipment and your projects to significant, avoidable risks. The primary issues are the permanent buildup of ink and adhesives on your heat platen, which can contaminate and ruin future garments, and the direct exposure of fabric to intense heat, which can cause scorching or discoloration.

A Teflon sheet is not just an accessory; it is a fundamental component for protecting the longevity of your heat press and ensuring the consistent quality of your work. Skipping it saves seconds but risks permanent damage to your equipment and materials.

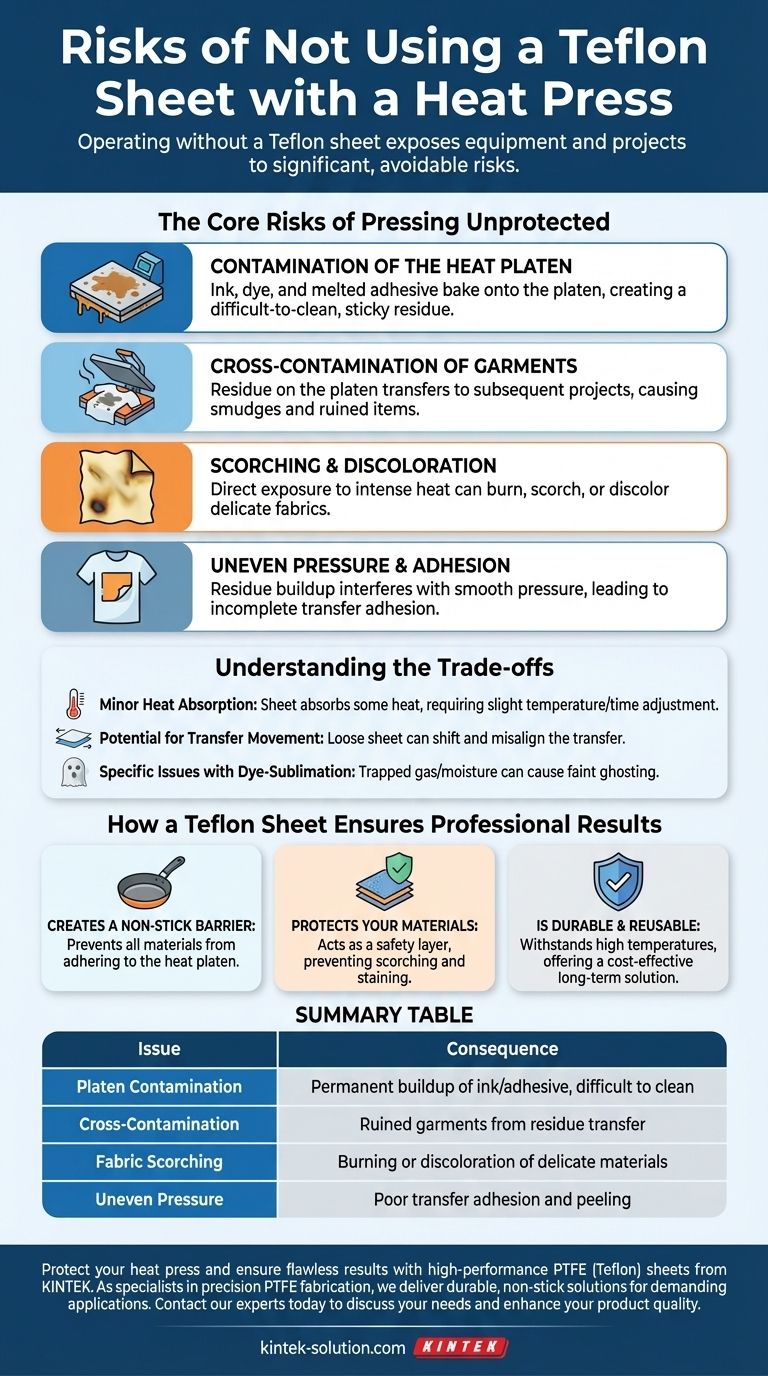

The Core Risks of Pressing Unprotected

Failing to use a protective barrier between your project and your heat press introduces several problems that compound over time. These issues directly impact both your equipment's health and your final product's quality.

Contamination of the Heat Platen

Without a non-stick sheet, excess ink, dye, and melted adhesive from transfers can bake directly onto the upper platen of your press. This creates a sticky, stained residue that is extremely difficult to clean once cured by heat.

Cross-Contamination of Garments

The residue built up on the platen doesn't just stay there. During your next press, this gunk can transfer onto a new, clean garment, causing smudges and stains that will ruin the item.

Scorching and Discoloration

A Teflon sheet acts as a crucial buffer, diffusing the intense, direct heat from the platen. Without it, delicate fabrics are far more susceptible to scorching, burning, or yellowing under high temperatures.

Uneven Pressure and Adhesion

While minor, any existing residue on a platen can create an uneven surface. This can interfere with the smooth, even pressure required for a perfect transfer, potentially leading to peeling or incomplete adhesion.

Understanding the Trade-offs

While highly recommended, it is important to understand that using a Teflon sheet is not without its own set of considerations. Being aware of these allows you to mitigate them effectively.

Minor Heat Absorption

The sheet itself can absorb a small amount of heat from the platen. This may require you to slightly increase your temperature or pressing time to ensure the transfer receives the manufacturer-recommended heat level.

Potential for Transfer Movement

A loose Teflon sheet can shift when you close the press. This movement can drag the transfer with it, resulting in a crooked or misaligned final print. Always ensure your sheet and transfer are secured.

Specific Issues with Dye-Sublimation

For some processes, particularly dye-sublimation, a Teflon sheet can sometimes trap excess gas and moisture, which may contribute to a faint "ghosting" or bleeding effect in the final print.

How a Teflon Sheet Ensures Professional Results

The benefits of using a Teflon sheet are directly tied to preventing the problems listed above. It is a simple tool that provides multiple layers of essential protection.

It Creates a Non-Stick Barrier

The primary function is its non-stick surface. This ensures that no materials—from vinyl backing to sublimation ink—will ever adhere to your heat platen, keeping it pristine.

It Protects Your Materials

The sheet provides a safety layer that prevents scorching and staining, allowing you to press with confidence, especially on heat-sensitive or light-colored fabrics.

It Is Durable and Reusable

Teflon sheets are designed to withstand high temperatures repeatedly. This makes them a highly cost-effective and long-term solution for protecting your investment.

Making the Right Choice for Your Goal

Your approach should be guided by your commitment to quality and consistency.

- If your primary focus is protecting your investment: Always use a Teflon sheet to prevent the permanent buildup of residue that can damage your heat platen over time.

- If your primary focus is maximum print consistency: A sheet is non-negotiable for preventing cross-contamination between jobs and protecting delicate fabrics from scorching.

- If you are working with specialty transfers like dye-sublimation: Use a sheet but remain aware of potential ghosting, and ensure your substrate and paper are completely dry before pressing.

Ultimately, incorporating a Teflon sheet into your workflow is a simple, professional habit that prevents costly mistakes.

Summary Table:

| Issue | Consequence |

|---|---|

| Platen Contamination | Permanent buildup of ink/adhesive, difficult to clean |

| Cross-Contamination | Ruined garments from residue transfer |

| Fabric Scorching | Burning or discoloration of delicate materials |

| Uneven Pressure | Poor transfer adhesion and peeling |

Protect your heat press and ensure flawless results with high-performance PTFE (Teflon) sheets from KINTEK.

As specialists in precision PTFE fabrication for demanding industries, we understand the need for durable, non-stick solutions that withstand high heat and pressure. Our PTFE sheets are engineered to provide a reliable barrier, preventing contamination and fabric damage, just like the protection needed for your heat press.

Whether you need standard sizes or custom-fabricated components for specialized applications, KINTEK delivers the quality and consistency your business depends on.

Contact our experts today to discuss your needs and discover how our PTFE components can safeguard your equipment and enhance your product quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs