For challenging storage conditions, PTFE lined caps offer a trifecta of advantages that make them the definitive choice for volatile liquids and high-temperature applications. Their primary benefits are extreme chemical inertness, exceptional performance at high temperatures, and the ability to form a highly reliable, leak-proof seal. This unique combination ensures the integrity of the container's contents while preventing dangerous leaks or contamination.

The core issue isn't just finding a cap that fits; it's about creating a stable, inert barrier between your sample and the outside world. PTFE liners excel because they are chemically non-reactive and physically resilient under conditions where other materials would fail, degrade, or melt.

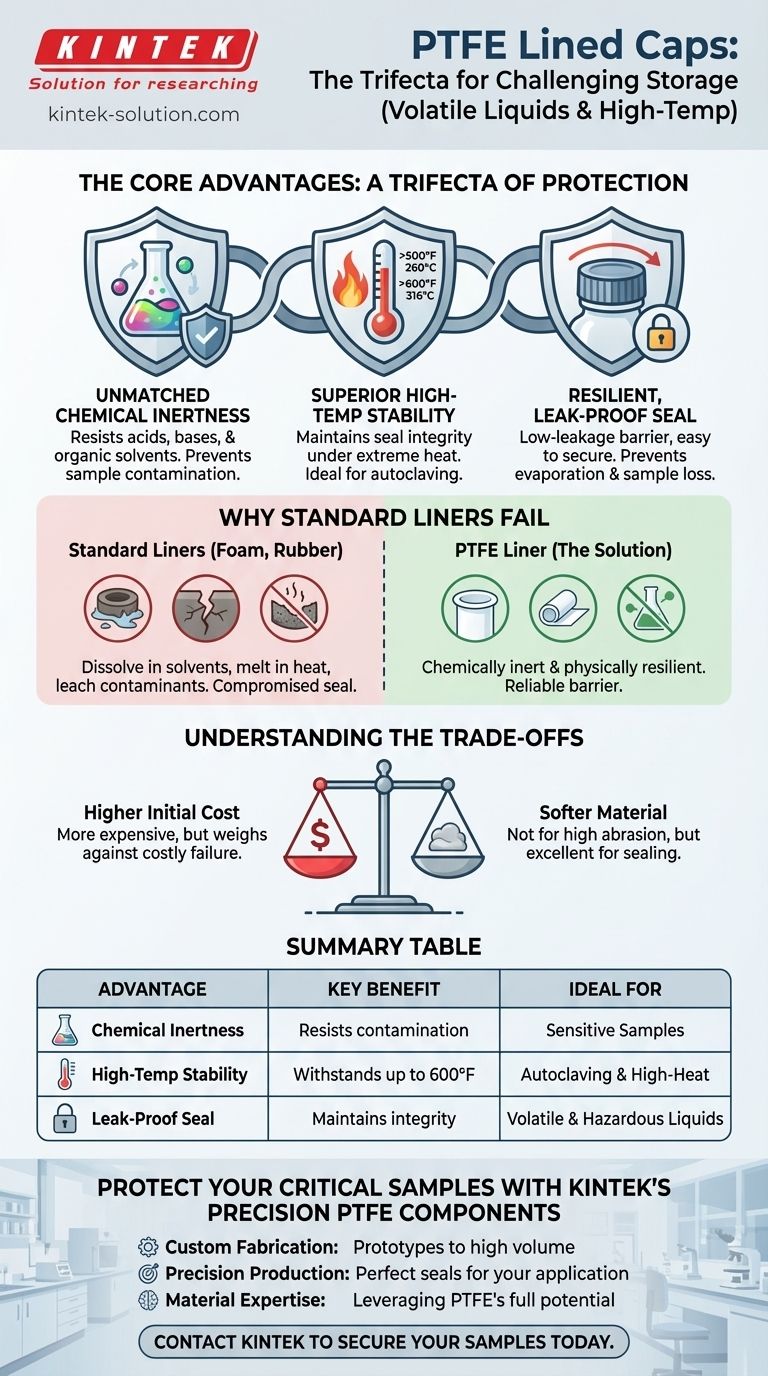

Why Standard Liners Fail in Extreme Conditions

Many standard cap liners are made from materials like polyethylene foam or rubber. While suitable for general-purpose storage, they quickly become a liability when exposed to aggressive chemicals or high heat.

These materials can be dissolved by organic solvents, degraded by corrosive acids, or melt during high-temperature processes like autoclaving. This failure not only compromises the seal but also leaches contaminants into the sample, invalidating results or ruining the product.

The Core Advantages of a PTFE Liner

A Polytetrafluoroethylene (PTFE) liner overcomes these limitations by acting as a robust, chemically inert barrier. Its properties make it uniquely suited for the most demanding laboratory and industrial applications.

Unmatched Chemical Inertness

The defining feature of PTFE is its superior corrosion resistance. It is virtually non-reactive with almost all chemicals, including aggressive acids, bases, and organic solvents that would destroy lesser materials.

This inertness is critical when storing volatile liquids, which are often chemically aggressive. A PTFE liner ensures that the cap itself does not become a source of contamination, preserving the purity of the material inside.

Superior High-Temperature Stability

PTFE liners maintain their structural integrity and sealing properties at extreme temperatures. Some grades can withstand continuous use at temperatures exceeding 500°F (260°C) and even up to 600°F (316°C).

This makes them ideal for applications involving high-temperature storage or sterilization cycles. Unlike other materials that can soften, warp, or melt, a PTFE liner remains stable, ensuring the seal is not compromised by heat.

A Resilient, Leak-Proof Seal

PTFE creates an excellent, low-leakage seal with minimal torque. This is vital for containing volatile liquids, where even microscopic gaps can lead to evaporation and sample loss.

The material's properties allow it to maintain seal integrity even under high-pressure conditions. Furthermore, PTFE's famously low coefficient of friction means caps are easy to secure and open without sticking or binding, reducing the risk of spills or breakage.

Understanding the Trade-offs

While PTFE offers significant advantages, it's important to be aware of its limitations to make a fully informed decision. No material is perfect for every single use case.

Higher Initial Cost

The most notable trade-off is cost. PTFE-lined caps are more expensive than their standard foam or rubber-lined counterparts. This cost must be weighed against the potential cost of a failed seal: sample loss, contamination, or safety hazards.

Softer Material Properties

PTFE is a relatively soft polymer. While this helps it form an excellent seal, it is not ideal for applications requiring high abrasion resistance. For a static cap liner, this is rarely an issue, but it is a factor to consider in the material's overall profile.

Selecting the Right Cap for Your Application

Your choice of cap liner should be directly informed by the demands of your specific task. The primary goal is always to protect the integrity of the contents.

- If your primary focus is preventing contamination of sensitive samples: PTFE's unparalleled chemical inertness makes it the only choice to ensure purity.

- If your primary focus is storing volatile or hazardous liquids: The combination of a leak-proof seal and extreme chemical resistance is essential for safety and sample preservation.

- If your primary focus is applications involving high heat (e.g., autoclaving): PTFE's high-temperature stability ensures the seal remains intact when other liners would melt and fail.

Ultimately, choosing a PTFE lined cap is an investment in reliability and sample security.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists acids, bases, and solvents | Preventing sample contamination |

| High-Temp Stability | Withstands temperatures up to 600°F (316°C) | Autoclaving and high-heat storage |

| Leak-Proof Seal | Maintains seal integrity with minimal torque | Containing volatile or hazardous liquids |

Protect your most critical samples with KINTEK's precision PTFE components.

When sample integrity is non-negotiable, our custom-fabricated PTFE liners, seals, and labware provide the definitive barrier against contamination and leakage. We serve semiconductor, medical, laboratory, and industrial clients who cannot afford failure.

Let us deliver the reliability you need:

- Custom Fabrication: From prototypes to high-volume orders.

- Precision Production: Ensuring perfect seals for your specific application.

- Material Expertise: Leveraging PTFE's full potential for your demanding conditions.

Contact KINTEK today to discuss your project requirements and secure your samples with confidence.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of using PTFE chromatography vials? Ensure Sample Integrity and Accurate Results

- What are the main benefits of PTFE filters? Achieve Unmatched Chemical Resistance and Purity

- Why are PTFE lined vials considered durable? Superior Chemical & Thermal Resistance for Reliable Performance

- What configurations are available for PTFE chromatography vials? Select the Right Vial for Your Analysis

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- In what types of laboratory equipment are Teflon membranes commonly used? Ensuring Purity in Demanding Applications

- What role does precision play in the use of PTFE silicone septa for pharmaceutical analysis? Ensure Reliable, Compliant Data

- How do PTFE syringe filters compare to membrane filters? A Guide to Chemical Compatibility