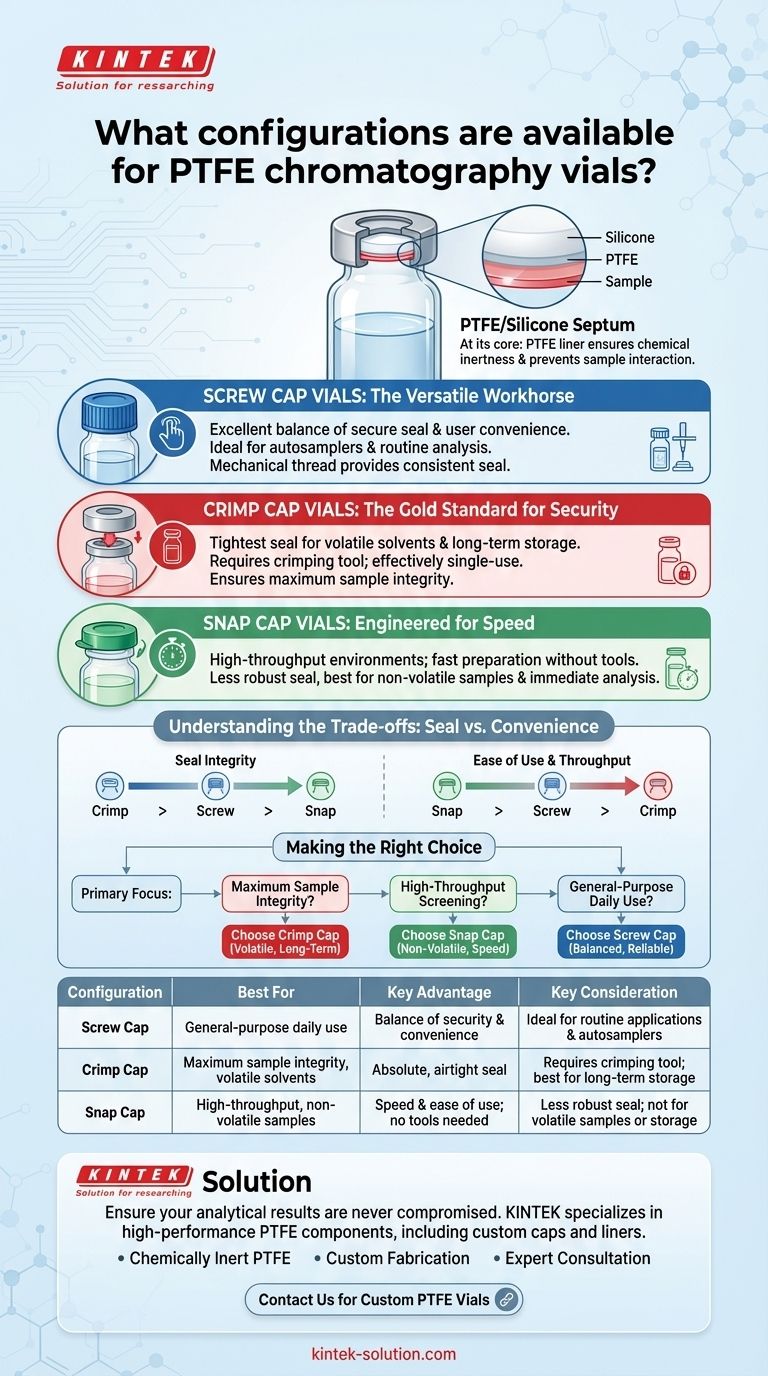

At its core, a PTFE chromatography vial is available in three primary configurations: screw cap, crimp cap, and snap cap. Each design provides a different balance of sealing security, ease of use, and compatibility with automation, allowing you to select the optimal vial for a specific analytical task. The "PTFE" aspect most critically refers to the liner within the cap's septum, which ensures chemical inertness and prevents sample interaction.

The choice of a chromatography vial configuration is not merely about preference; it is a technical decision that directly impacts sample integrity. The central trade-off is between the absolute security of a crimp seal and the convenience of a screw or snap cap.

Why PTFE is the Standard for High-Performance Vials

Before examining the configurations, it's crucial to understand why PTFE (Polytetrafluoroethylene) is the material of choice for demanding chromatography applications. Its properties are essential for generating reliable and reproducible data.

The Impact of Chemical Inertness

PTFE is virtually inert to almost all chemicals and solvents used in chromatography. This ensures that the vial or its cap liner does not react with your sample, leach impurities into it, or degrade over time.

Minimizing Sample Loss and Adsorption

One of the greatest challenges in trace analysis is the loss of analyte to the surface of the container. PTFE has an extremely low-friction, non-stick surface that drastically reduces the adsorption of sample molecules, ensuring what you inject is representative of what was in your vial.

Ensuring a Secure, Contaminant-Free Seal

The combination of PTFE's flexibility and inertness creates a superior sealing surface when used as a cap liner (septum). It forms a tight barrier against the vial rim, effectively preventing solvent evaporation and protecting the sample from atmospheric contamination.

A Breakdown of Vial Cap Configurations

While the vial itself is typically glass or polymer, the cap mechanism defines its performance characteristics. The critical component is often the PTFE/Silicone septum inside the cap, where the PTFE layer faces the sample.

Screw Cap Vials: The Versatile Workhorse

Screw cap vials are the most common type, offering an excellent balance between a secure seal and user convenience. The threaded cap is easy to tighten by hand and provides a reliable seal for most routine applications.

These vials are ideal for use with autosamplers and for analyses where samples will be run within a few hours to a few days. The mechanical action of the thread provides a consistent and firm seal.

Crimp Cap Vials: The Gold Standard for Security

When sample integrity is non-negotiable, crimp caps are the definitive choice. An aluminum cap is placed over the vial and physically crimped into place with a special tool.

This method provides the tightest possible seal, making it essential for highly volatile solvents, long-term sample storage, or sensitive analyses where even minimal evaporation could alter concentrations. The trade-off is that they require a tool and are effectively single-use.

Snap Cap Vials: Engineered for Speed

Snap cap vials are designed for high-throughput environments where speed is more critical than a perfect seal. The cap simply snaps onto the rim of the vial, allowing for very fast sample preparation without tools or twisting.

While convenient, the seal is less robust than that of screw or crimp caps. They are best suited for non-volatile samples and immediate analysis, as they are more prone to evaporation over time.

Understanding the Trade-offs: Seal vs. Convenience

Choosing the right vial means weighing the needs of your specific analysis. There is no single "best" option, only the most appropriate one for the task.

Seal Integrity and Sample Volatility

For protecting against evaporation, the hierarchy is clear. Crimp caps offer the most secure seal, followed by screw caps. Snap caps provide the least resistance to solvent loss and are not recommended for volatile samples or long-term storage.

Ease of Use and Throughput

The order is reversed for convenience. Snap caps are the fastest to seal and open. Screw caps are also simple to use by hand. Crimp caps are the slowest, as they require dedicated crimping and decapping tools for every vial.

Automation and Piercing

Most modern autosamplers are compatible with all three types, but crimp and screw caps often provide more reliable performance. Their rigid and consistent seal prevents the needle from pushing the septum into the vial, a potential issue with improperly seated snap caps. The PTFE/Silicone septum is designed to be pierced cleanly and to reseal effectively after injection.

Making the Right Choice for Your Analysis

Your analytical goal should dictate your vial choice. Use these guidelines to make a confident decision.

- If your primary focus is maximum sample integrity: Choose crimp cap vials to eliminate any risk of evaporation, especially for volatile analytes or long-term storage.

- If your primary focus is high-throughput screening: Choose snap cap vials for their speed and ease of use with non-volatile samples that will be analyzed quickly.

- If your primary focus is general-purpose daily use: Choose screw cap vials as they provide a reliable seal with excellent convenience, making them the balanced choice for most labs.

Ultimately, selecting the correct vial configuration is a foundational step in ensuring the quality and accuracy of your chromatographic results.

Summary Table:

| Configuration | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Screw Cap | General-purpose daily use | Balance of security and convenience | Ideal for most routine applications and autosamplers |

| Crimp Cap | Maximum sample integrity, volatile solvents | Absolute, airtight seal | Requires a crimping tool; best for long-term storage |

| Snap Cap | High-throughput, non-volatile samples | Speed and ease of use; no tools needed | Less robust seal; not for volatile samples or storage |

Ensure your analytical results are never compromised by your sample vials.

The right PTFE vial configuration is critical for protecting sample integrity, preventing evaporation, and ensuring compatibility with your autosampler. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom chromatography vial caps and liners for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Chemically Inert PTFE: Guaranteed non-reactive surfaces to protect sensitive samples.

- Custom Fabrication: From prototype designs to high-volume production orders.

- Expert Consultation: To help you select or design the optimal vial configuration for your specific application.

Contact us today to discuss your requirements and get a quote for PTFE vials that meet your exact specifications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications