In short, Teflon (PTFE) membranes are commonly used in laboratory equipment where chemical inertness and temperature resistance are critical. You will find them in filtration systems, chromatography equipment, liquid handling devices, and various tools for sample preparation, where they prevent contamination and ensure the integrity of experimental results.

The core reason for Teflon's prevalence in the lab is its unique combination of properties: it is almost universally non-reactive, withstands extreme temperatures, and has a non-stick surface. This makes it an ideal material for ensuring that the equipment itself does not interfere with the experiment.

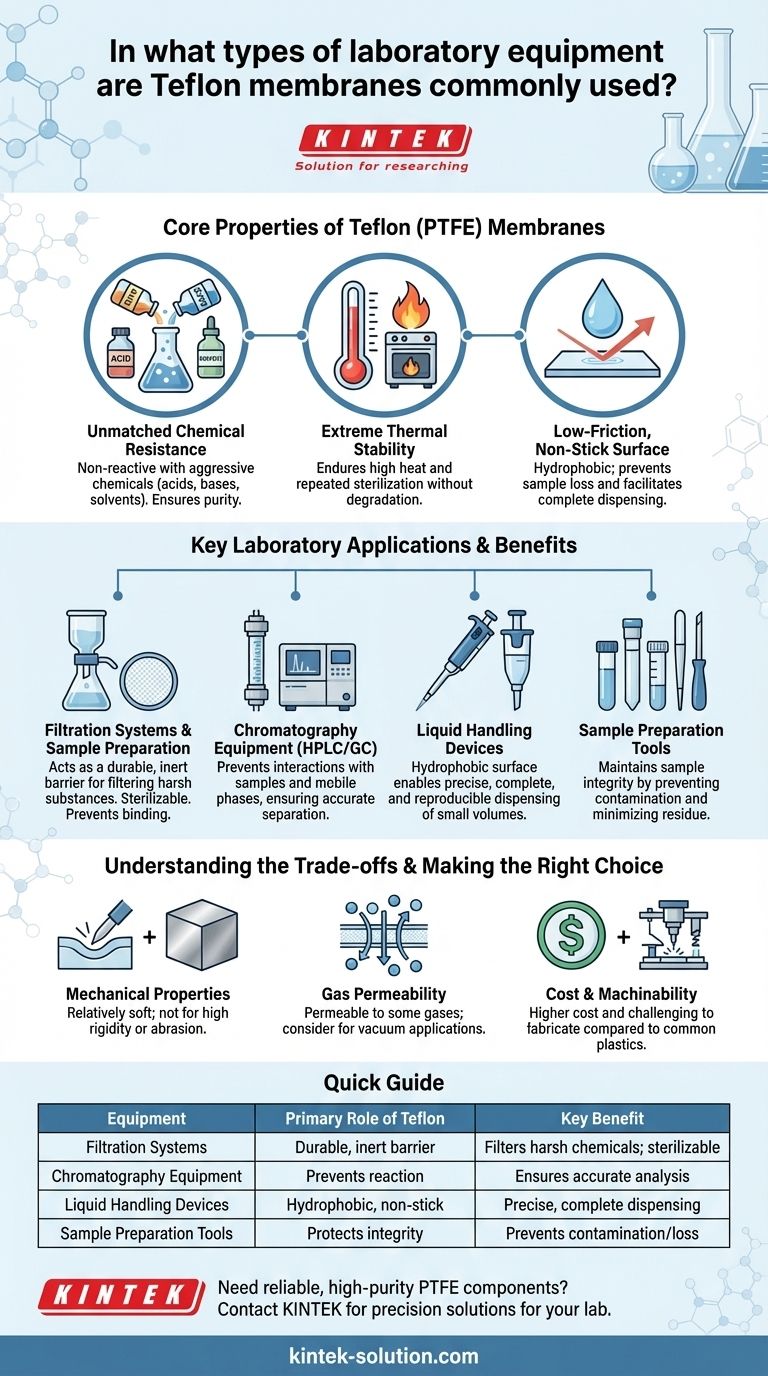

The Fundamental Properties of Teflon (PTFE) Membranes

To understand why Teflon is so widely used, we must first look at its core characteristics. Teflon, or polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer valued for a specific set of high-performance traits.

Unmatched Chemical Resistance

Teflon is exceptionally non-reactive and compatible with a vast range of chemicals, including aggressive acids, bases, and organic solvents.

This inertness makes it suitable for both aqueous and non-aqueous environments, ensuring the membrane will not degrade or leach contaminants into the sample.

Extreme Thermal Stability

These membranes can endure very high temperatures without losing their structural integrity or mechanical properties.

This makes them ideal for processes that involve heat, such as autoclaving for sterilization, where other materials would melt or deform.

Low-Friction, Non-Stick Surface

The surface of Teflon is inherently low-friction and hydrophobic, meaning liquids—especially aqueous solutions—do not stick to it.

This property is critical for preventing sample loss, as it ensures that the entire volume of a substance passes through the device without leaving residue behind.

Key Laboratory Applications Explained

The properties of Teflon directly translate into performance benefits across several categories of laboratory equipment, enhancing precision and reliability.

Filtration and Sample Preparation

In filtration systems, Teflon membranes act as a durable barrier. Their chemical resistance allows them to filter harsh substances without breaking down.

Their thermal stability means filter holders and assemblies can be sterilized repeatedly without damage, and their non-stick nature prevents the sample from binding to the filter itself.

Gas and Liquid Chromatography

Chromatography relies on the precise separation of components within a mixture. Teflon's inertness is paramount here.

Using Teflon components ensures that no part of the equipment reacts with the sample or the mobile phase, which could otherwise create false peaks or interfere with the separation process.

Liquid Handling and Dispensing

In devices like automated pipettes or dispensers, the goal is to move precise volumes of liquid.

Teflon's hydrophobic surface facilitates controlled, complete dispensing. It minimizes the risk of droplets clinging to the device, which is crucial for maintaining accuracy, especially with small volumes.

Understanding the Trade-offs

While Teflon's properties are highly advantageous, it is important to understand its limitations to make informed decisions. Its strengths in one area create trade-offs in others.

Mechanical Properties

Teflon is a relatively soft material. While chemically robust, it is not ideal for applications requiring high rigidity or resistance to physical abrasion compared to materials like stainless steel or certain other polymers.

Gas Permeability

Though it's a solid barrier for liquids, PTFE is permeable to certain gases. This is a critical consideration in applications requiring a perfect vacuum or the strict separation of gaseous environments.

Cost and Machinability

As a high-performance polymer, Teflon is often more expensive than common plastics like polypropylene or polyethylene. It can also be more challenging to fabricate into complex shapes.

Making the Right Choice for Your Goal

Selecting the right material is a crucial step in experimental design. Your primary objective will determine whether Teflon is the optimal choice.

- If your primary focus is sample purity and preventing contamination: Teflon's chemical inertness and non-stick surface make it the definitive choice to ensure your sample is not altered by your equipment.

- If your primary focus is working with aggressive chemicals or high temperatures: Teflon's stability is non-negotiable for ensuring the safety and longevity of your apparatus.

- If your primary focus is precision in small-volume liquid handling: Teflon's hydrophobic properties are essential for complete sample delivery and achieving accurate, repeatable measurements.

Ultimately, selecting Teflon is a decision to prioritize chemical and thermal reliability in demanding laboratory environments.

Summary Table:

| Laboratory Equipment | Primary Role of Teflon Membrane | Key Benefit |

|---|---|---|

| Filtration Systems | Acts as a durable, inert barrier | Filters harsh chemicals; can be sterilized |

| Chromatography Equipment | Prevents reaction with sample/mobile phase | Ensures accurate separation and analysis |

| Liquid Handling Devices | Provides a hydrophobic, non-stick surface | Enables precise, complete liquid dispensing |

| Sample Preparation Tools | Protects sample integrity | Prevents contamination and sample loss |

Need reliable, high-purity PTFE components for your lab?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom membranes—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment delivers contamination-free results, even with aggressive chemicals and high temperatures.

From prototypes to high-volume orders, we provide custom fabrication to meet your exact specifications. Contact us today to discuss how our PTFE solutions can enhance the integrity and reliability of your laboratory processes.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments