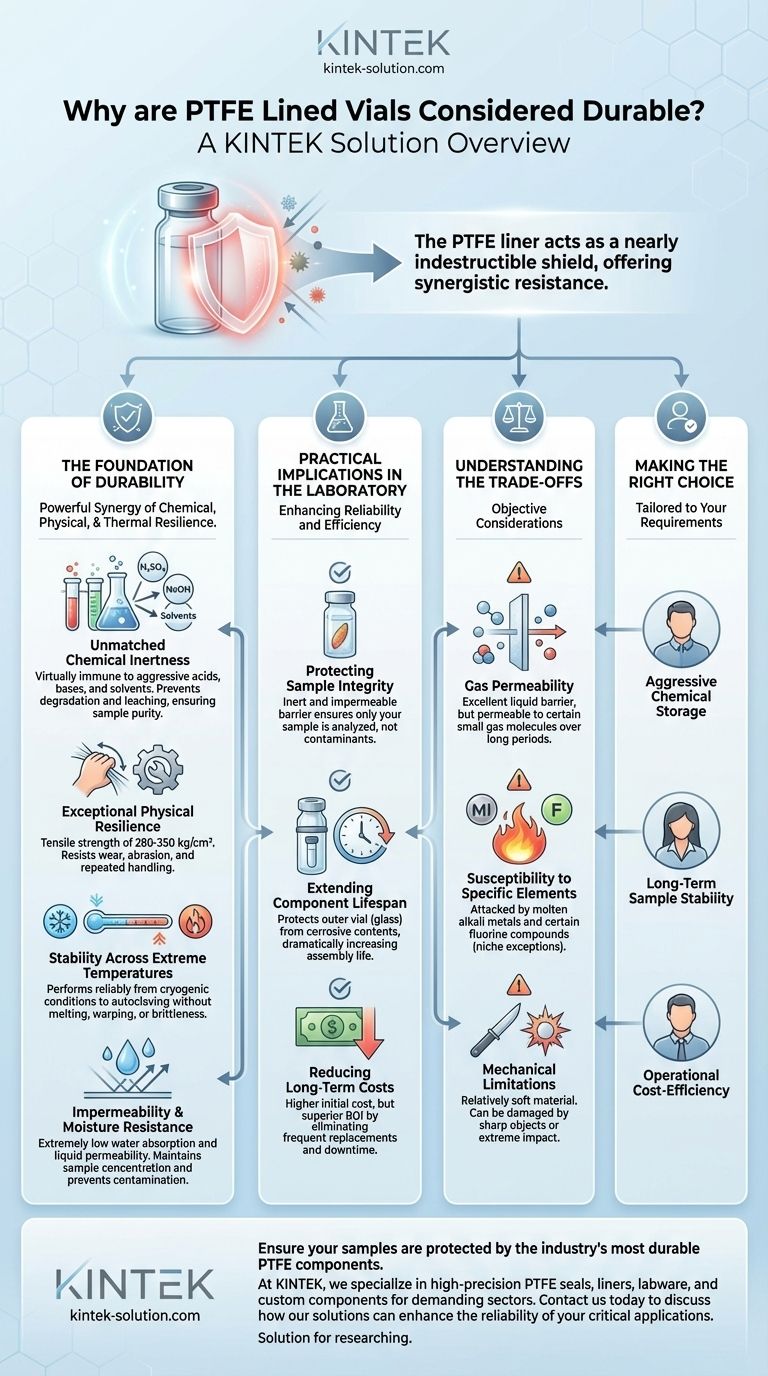

To put it simply, PTFE-lined vials are considered durable because the Polytetrafluoroethylene (PTFE) liner acts as a nearly indestructible shield. This material is exceptionally resistant to chemical attack, physical wear and tear, and extreme temperatures. This combination of properties ensures the vial maintains its structural integrity and protects its contents under demanding laboratory conditions.

The durability of PTFE is not a single characteristic but a powerful synergy of its chemical, physical, and thermal resilience. It creates a stable, non-reactive barrier that maintains its integrity under conditions that would degrade or destroy most other materials, ensuring both sample purity and long-term performance.

The Foundation of PTFE's Durability

To understand why PTFE is so robust, we must look at its core material properties. Each contributes to its reputation as a high-performance material for critical applications.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It is virtually immune to attack from aggressive acids, bases, solvents, and other corrosive chemicals. This inertness prevents the liner from degrading, corroding, or leaching impurities into the sample, which is critical for analytical work.

Exceptional Physical Resilience

The material exhibits impressive mechanical strength. With a tensile strength of 280-350 kg/cm², it resists being pulled apart. Its resistance to wear and abrasion means it can withstand repeated handling, mixing, and contact with other equipment without scratching or breaking down.

Stability Across Extreme Temperatures

PTFE performs reliably across a vast temperature range. It remains flexible at cryogenic temperatures and is stable at high temperatures, allowing it to be used in processes like autoclaving without melting, warping, or becoming brittle.

Impermeability and Moisture Resistance

The material has extremely low water absorption and very low permeability to liquids. This moisture resistance is crucial for preventing the sample from becoming diluted or contaminated by external moisture over the long term, ensuring concentration and purity are maintained.

Practical Implications in the Laboratory

These intrinsic properties translate directly into tangible benefits that enhance reliability and efficiency in a lab or industrial setting.

Protecting Sample Integrity

The primary function of a vial is to contain a sample without altering it. Because the PTFE liner is so inert and impermeable, it provides a perfect barrier, ensuring that the only thing you analyze is your sample, not contaminants from the container.

Extending Component Lifespan

In many cases, the PTFE liner protects the outer vial material (often glass) from its contents. By preventing corrosive chemicals from ever touching the structural part of the vial, the liner dramatically increases the entire assembly's lifespan.

Reducing Long-Term Costs

While PTFE-lined vials may have a higher initial cost, their longevity provides a superior return on investment. The need for frequent replacement is eliminated, which reduces material costs, waste, and the operational downtime associated with vial failure.

Understanding the Trade-offs

No material is perfect for every application. Being objective means acknowledging the specific limitations of PTFE.

Gas Permeability

While PTFE is an excellent barrier against liquids, it can be permeable to certain small gas molecules over long periods. This is a critical consideration for applications involving the long-term storage of specific gases where even minute loss is unacceptable.

Susceptibility to Specific Elements

Although chemically inert to almost everything, PTFE can be attacked by a few highly reactive substances, such as molten alkali metals and certain fluorine compounds. These are niche exceptions but are important to be aware of.

Mechanical Limitations

PTFE is a relatively soft material. While it resists abrasion well, it can be damaged by sharp objects or extreme mechanical force. It is not designed to withstand high-impact physical abuse.

Making the Right Choice for Your Application

Ultimately, the decision to use a PTFE-lined vial should be based on your specific requirements.

- If your primary focus is aggressive chemical storage: PTFE's unparalleled chemical inertness makes it the definitive choice for preventing container degradation and sample contamination.

- If your primary focus is long-term sample stability: The combination of low permeability and resistance to environmental factors ensures your sample remains pure and unaltered over time.

- If your primary focus is operational cost-efficiency: The extended lifespan and reduced need for replacement make PTFE-lined vials a strategic investment, justifying their initial cost.

By understanding its fundamental properties, you can see that choosing a PTFE-lined vial is an investment in reliability, ensuring the integrity of both your samples and your results.

Summary Table:

| Property | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, preventing degradation and sample contamination. |

| High Tensile Strength (280-350 kg/cm²) | Withstands physical stress, handling, and abrasion without breaking down. |

| Extreme Temperature Stability | Performs reliably from cryogenic to high autoclaving temperatures without warping or becoming brittle. |

| Low Water Absorption & Impermeability | Protects sample integrity by preventing moisture ingress and dilution over the long term. |

Ensure your samples are protected by the industry's most durable PTFE components.

At KINTEK, we specialize in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your specific chemical resistance and durability needs.

Contact us today to discuss how our PTFE components can enhance the reliability and longevity of your critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications