The primary advantages of using PTFE in plain bearings are its exceptionally low coefficient of friction, inherent self-lubricating properties, and high resistance to chemicals and wear. When used as a liner or integrated into a metallic matrix, PTFE eliminates the need for external lubrication like oil or grease, which drastically reduces maintenance requirements and improves operational reliability in a wide range of conditions.

The core problem with many traditional bearings is their reliance on external lubrication, which introduces complexity, requires ongoing maintenance, and creates a failure point in contaminated or corrosive environments. PTFE plain bearings solve this by creating a maintenance-free system that simplifies mechanical design, extends service life, and ensures consistent, smooth performance.

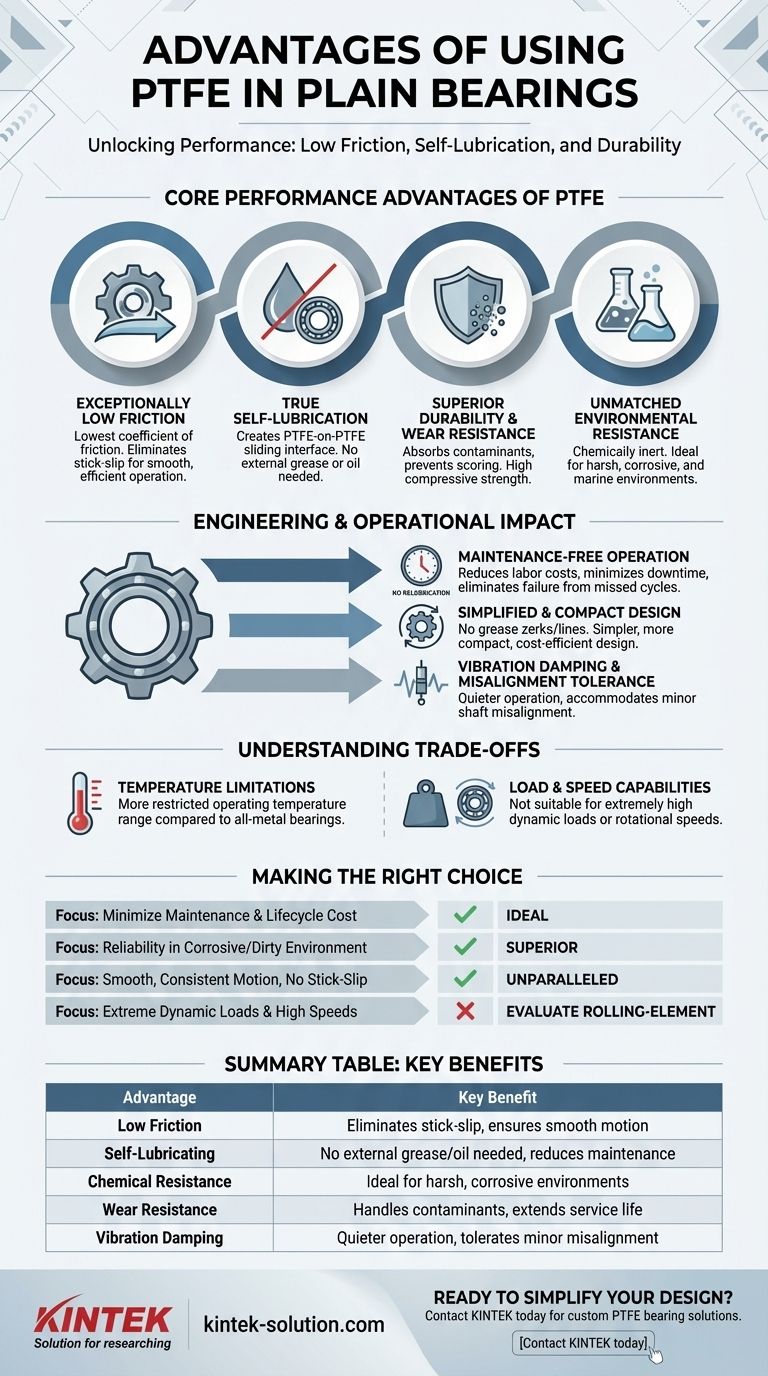

The Core Performance Advantages of PTFE

Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it a superior material for the sliding layer in plain bearings.

Exceptionally Low Friction

PTFE boasts the lowest coefficient of friction of any known solid material. This intrinsic property ensures smooth, efficient operation from the first moment of movement.

Crucially, this low friction helps to eliminate "stick-slip", a phenomenon of jerking motion at low speeds that can plague traditionally lubricated systems. The friction coefficient can even decrease as pressure increases, ensuring consistent performance under load.

True Self-Lubrication

The material's molecular structure allows it to transfer a thin film to the mating metal surface, creating a highly effective PTFE-on-PTFE sliding interface.

This self-lubricating nature completely removes the need for external grease or oil. As a result, the bearing does not attract dirt, dust, or other contaminants that can accelerate wear in lubricated joints.

Superior Durability and Wear Resistance

When integrated into a bearing structure, such as a liner woven into a metallic backing, PTFE exhibits excellent durability. It can absorb small contaminant particles, embedding them into its surface and preventing them from scoring or damaging the mating shaft.

PTFE also possesses high compressive strength, allowing it to handle significant static loads without deforming. This makes it a robust choice for many structural and industrial applications.

Unmatched Environmental Resistance

PTFE is chemically inert, meaning it is virtually unaffected by solvents, acids, and other corrosive substances. This makes PTFE-lined bearings ideal for use in chemical processing, marine, and other harsh environments where traditional bearings would quickly degrade.

Furthermore, it acts as an electrical and thermal insulator, which can be a critical design advantage in specific applications.

The Engineering and Operational Impact

These material properties translate directly into significant practical benefits for designers, operators, and maintenance teams.

Maintenance-Free Operation

The most significant operational advantage is the elimination of maintenance. There is no need for a relubrication schedule, which reduces labor costs, minimizes downtime, and removes the risk of bearing failure due to missed lubrication cycles.

Simplified and Compact Design

Without the need for grease zerks, oil lines, or sealing systems, the overall mechanical design can be simpler, more compact, and more cost-efficient. This simplicity also allows for tighter fits and reduced internal clearances, leading to more precise movement.

Vibration Damping and Misalignment Tolerance

The slightly compliant nature of a PTFE liner helps to dampen vibrations within a mechanical system, leading to quieter operation. It can also accommodate minor shaft misalignment without a catastrophic loss in performance, adding a layer of resilience to the design.

Understanding the Trade-offs

While highly advantageous, PTFE bearings are not a universal solution. Understanding their limitations is key to successful application.

Temperature Limitations

Compared to all-metal bearings, PTFE has a more restricted operating temperature range. Extremely high temperatures generated by high-speed or high-load conditions can cause the material to degrade.

Load and Speed Capabilities

While static load capacity is excellent, PTFE plain bearings may not be suitable for applications with extremely high dynamic loads or rotational speeds. In such cases, the heat generated can exceed the material's limits, making a rolling-element bearing a more appropriate choice.

Material Selection is Critical

The performance of a "PTFE bearing" is highly dependent on its construction. A high-quality, reinforced PTFE liner bonded to a steel backing will have vastly different capabilities than a simple, molded PTFE component. Specifying the correct construction for the load and environment is essential.

Making the Right Choice for Your Application

Selecting the right bearing technology depends entirely on your primary design goals.

- If your primary focus is minimizing maintenance and lifecycle cost: A PTFE plain bearing is the ideal choice due to its self-lubricating, "fit and forget" nature.

- If your primary focus is reliability in a corrosive or dirty environment: PTFE's chemical inertness and ability to function without attracting contaminants make it the superior option.

- If your primary focus is smooth, consistent motion without stick-slip: PTFE's uniquely low coefficient of friction provides unparalleled performance, especially in oscillating or slow-moving applications.

- If your primary focus is managing extreme dynamic loads or very high speeds: You should evaluate whether a rolling-element (ball or roller) bearing is better suited to handle the resulting heat and stress.

By leveraging the unique properties of PTFE, you are choosing a solution engineered for simplicity, longevity, and predictable performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Friction | Eliminates stick-slip, ensures smooth motion |

| Self-Lubricating | No external grease/oil needed, reduces maintenance |

| Chemical Resistance | Ideal for harsh, corrosive environments |

| Wear Resistance | Handles contaminants, extends service life |

| Vibration Damping | Quieter operation, tolerates minor misalignment |

Ready to simplify your design and eliminate bearing maintenance?

KINTEK specializes in precision PTFE components, including custom plain bearing liners and seals for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a bearing solution engineered for your specific load, environment, and performance requirements.

Contact KINTEK today to discuss how our PTFE components can enhance your application's reliability and reduce lifecycle costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is the significance of PTFE's chemical inertness in instrumentation systems? Ensure Unmatched System Integrity and Accuracy

- Why are PTFE-lined bearings suitable for suspension parts? Achieve Maintenance-Free, High-Performance Suspension

- What are the temperature limits for PTFE in machining applications? Managing Thermal Expansion for Precision Parts

- Why are PTFE-lined diaphragm valves preferred in the pharmaceutical industry? Ensure Sterility & Product Purity

- How does PTFE coating enhance corrosion resistance in fasteners? Achieve Unmatched Protection in Harsh Environments

- Why is CNC machining suitable for custom Teflon parts? Achieve Precision for Demanding Applications

- What are the benefits of using Teflon sheets in heat press machines? Achieve Flawless Transfers & Protect Your Equipment

- What are the benefits of using a Teflon sheet for heat press? Achieve Flawless, Professional Transfers