In any heat press operation, a Teflon sheet serves as an essential protective barrier between your heat platen and your project. It prevents scorching, stops ink and adhesive from contaminating your materials or machine, and helps ensure even heat distribution for a clean, professional transfer every time. Its non-stick surface is critical for a flawless finish.

Think of a Teflon sheet not as an optional accessory, but as a fundamental component for quality control. It is the single most effective tool for protecting your investment—both your garments and your heat press—while ensuring the consistency of your work.

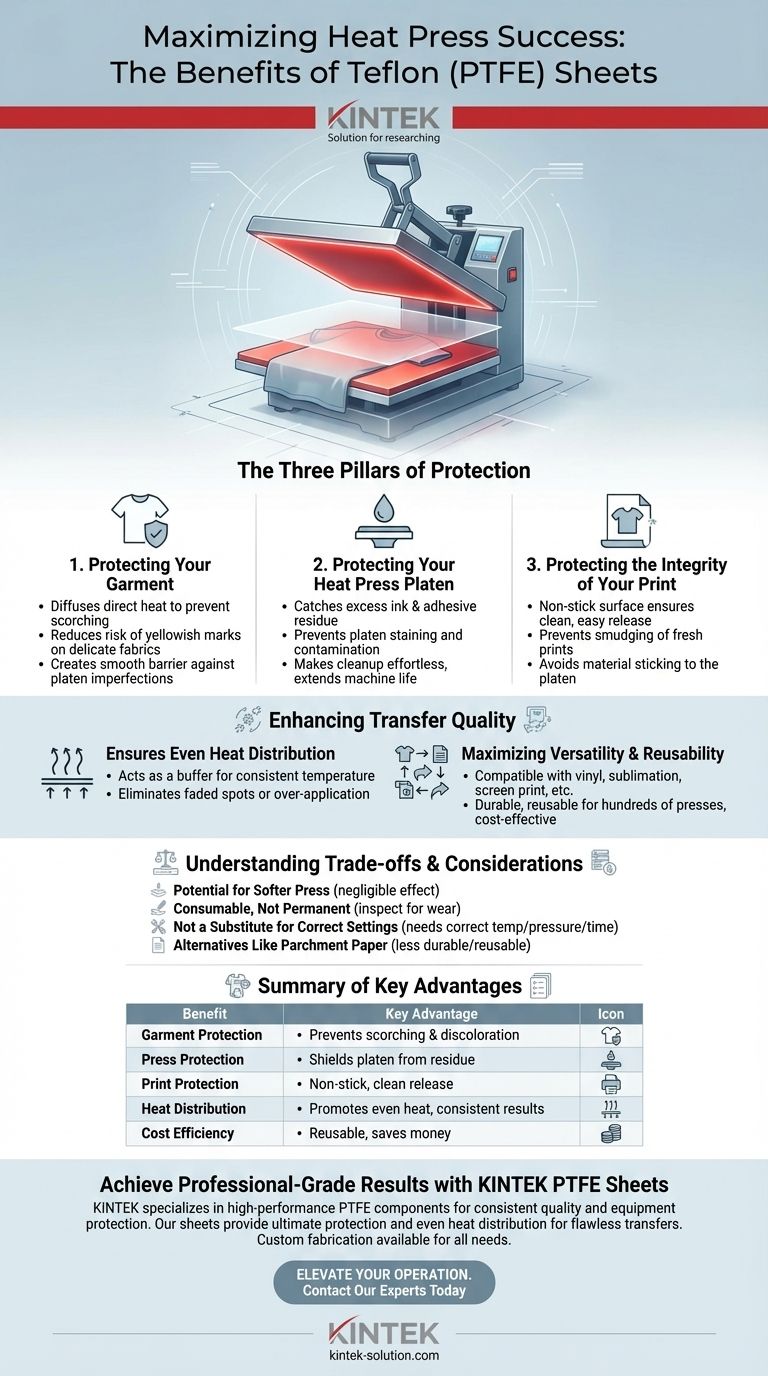

The Three Pillars of Protection: Garment, Press, and Print

The core function of a Teflon sheet is to act as a shield. It simultaneously protects the three most critical elements of any heat transfer job.

Protecting Your Garment from Damage

A Teflon sheet diffuses direct heat, significantly reducing the risk of scorching or leaving a yellowish mark on delicate or light-colored fabrics.

It also creates a smooth barrier that prevents any texture or imperfections on the heat platen from pressing into your material.

Protecting Your Heat Press Platen

During a press, excess ink (especially in sublimation) or adhesive from heat transfer vinyl (HTV) can seep onto the upper platen.

A Teflon sheet catches this residue, preventing it from staining the platen. This is crucial because a contaminated platen will transfer old ink or debris onto every subsequent project you create.

This protective layer makes cleanup effortless and extends the life of your machine.

Protecting the Integrity of Your Print

The non-stick surface is a key feature. It ensures that when you lift the heat press, the transfer material or garment does not stick to the platen, which could otherwise smudge or ruin the fresh print.

This allows for a clean, easy release of the garment immediately after pressing is complete.

How a Teflon Sheet Enhances Transfer Quality

Beyond simple protection, using a Teflon sheet actively improves the final result of your transfer.

Ensuring Even Heat Distribution

While high-quality heat presses are designed to heat evenly, minor temperature fluctuations can still occur across the platen.

The Teflon sheet acts as a buffer, helping to distribute the heat more evenly across the entire surface of your design. This consistency is vital for achieving a flawless transfer without faded spots or areas of over-application.

Maximizing Versatility and Reusability

Teflon sheets are compatible with virtually all heat press machines and transfer methods, including vinyl, sublimation, screen print transfers, and more.

Because they are durable and highly reusable, a single sheet can last for hundreds or even thousands of presses, offering significant long-term cost savings compared to disposable alternatives.

Understanding the Trade-offs and Considerations

While highly beneficial, it's important to understand the context of using a Teflon sheet. It is a tool, not a solution for poor technique.

Potential for a Softer Press

The sheet introduces a very thin layer between the platen and your garment. This can minutely decrease the direct pressure.

For most applications like HTV and sublimation, this effect is negligible and has no negative impact on the final result.

It's a Consumable, Not Permanent

While durable, Teflon sheets will eventually wear out. Be sure to inspect your sheet for any deep creases, wrinkles, or signs of wear that could potentially transfer an unwanted texture to your garment.

Not a Substitute for Correct Settings

A Teflon sheet cannot fix a project that uses the wrong temperature, pressure, or time. It is a protective measure that works in concert with correct machine settings, not in place of them.

Alternatives Like Parchment Paper

Parchment paper can be used as a disposable alternative. However, it lacks the durability, reusability, and superior non-stick properties of a proper Teflon sheet, making it a less cost-effective and reliable choice for professional or high-volume work.

Making the Right Choice for Your Goal

Using a protective sheet is almost always recommended. Your specific goal will simply reinforce its importance.

- If your primary focus is protecting delicate or light-colored fabrics: A Teflon sheet is non-negotiable to prevent scorching and discoloration.

- If your primary focus is high-volume production: The reusability of Teflon offers significant long-term cost savings and process consistency over disposable options.

- If your primary focus is achieving the cleanest transfer possible: Using a sheet prevents any residue from your platen contaminating your garment and stops fresh ink from smudging the platen itself.

Ultimately, incorporating a Teflon sheet into your workflow is a simple step that elevates your process from amateur to professional.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Garment Protection | Prevents scorching and discoloration on delicate fabrics. |

| Press Protection | Shields platen from ink/adhesive residue, extending machine life. |

| Print Protection | Non-stick surface ensures clean release and prevents smudging. |

| Heat Distribution | Promotes even heat for consistent, high-quality transfers. |

| Cost Efficiency | Reusable for hundreds of presses, saving money vs. disposables. |

Achieve Professional-Grade Heat Press Results with KINTEK PTFE Sheets

For heat press operators in the textile, promotional product, and customization industries, consistent quality and equipment protection are paramount. KINTEK specializes in manufacturing high-performance PTFE (Teflon) components, including durable, non-stick sheets designed for the rigors of heat pressing.

Our sheets are engineered to provide the ultimate protection for your garments and machine while ensuring even heat distribution for flawless transfers. We offer custom fabrication to meet your specific size and volume needs, from prototypes to high-volume orders.

Ready to elevate your heat press operation? Contact our experts today to discuss how our precision PTFE sheets can protect your investment and ensure consistent, professional results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some common applications of machined Teflon? Critical Components for Harsh Environments

- How should bonded PTFE be maintained to preserve bond strength? Protect Your Critical Components from Degradation

- What are some emerging trends in PTFE gasket technology? Innovations in Materials and Manufacturing

- How is the PTFE lining process carried out? A Guide to Flawless Corrosion Protection

- What industries commonly use PTFE bushings, and why? Solve Critical Engineering Challenges

- What factors should be considered when choosing between solid Teflon O-rings and Teflon encapsulated O-rings?

- What material are typical rotary seals made of and what are their limitations? Choose the Right Seal for Your Application

- What benefits does PTFE provide in athletic footwear? Enhancing Performance with Low-Friction & Non-Stick Solutions