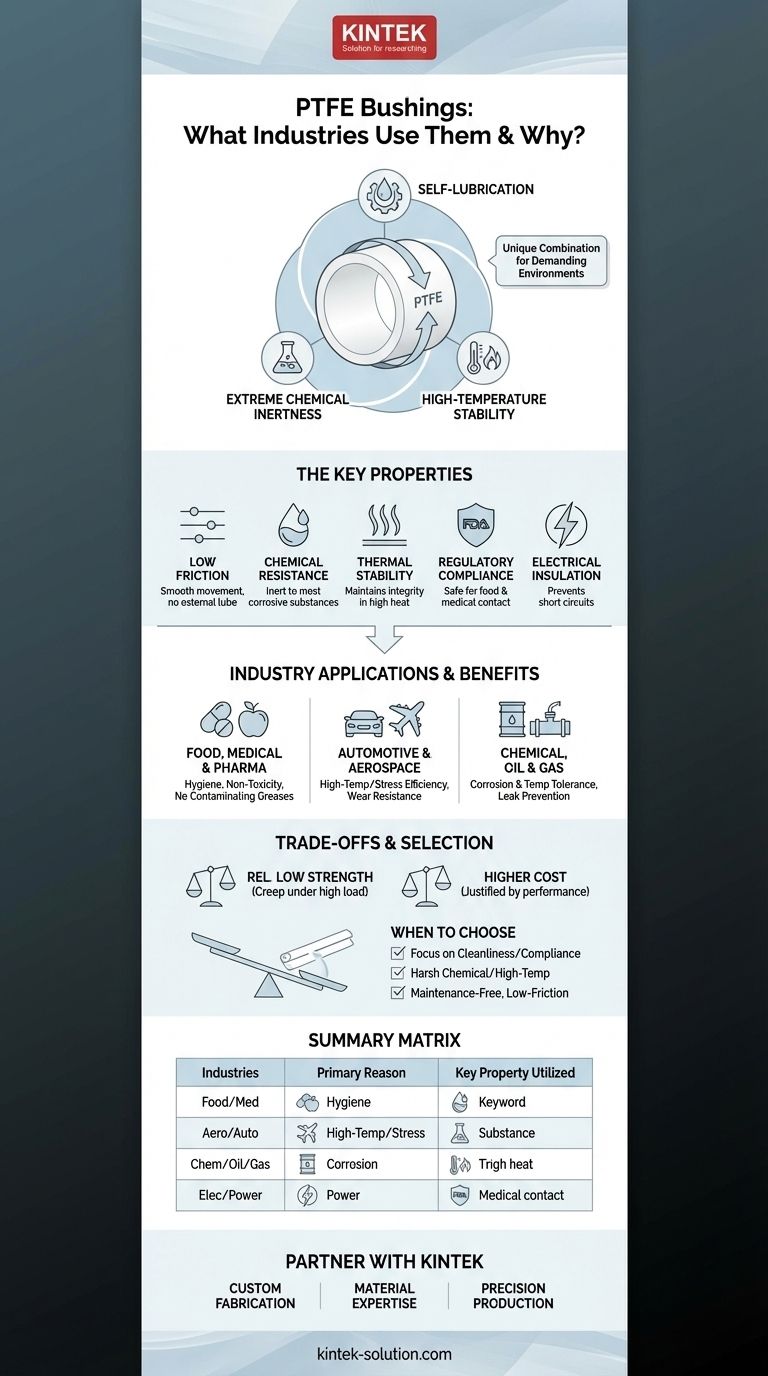

In short, PTFE bushings are used in nearly every demanding industry, including food processing, medical, aerospace, automotive, and chemical manufacturing. Their widespread adoption is due to a unique combination of properties that solve critical engineering challenges where other materials fail.

The core reason for PTFE's versatility is not a single feature, but its unique ability to combine self-lubrication, extreme chemical resistance, and high-temperature stability in one material, making it an essential problem-solver for demanding environments.

What is a PTFE Bushing? A Foundational Overview

The Core Function: A Simple Explanation

A PTFE bushing, also known as a sleeve or bearing, is a cylindrical component made from Polytetrafluoroethylene.

Its primary job is to create a low-friction surface between two moving parts, allowing them to slide or rotate smoothly without needing external lubrication like grease or oil.

The Material: Polytetrafluoroethylene (PTFE)

PTFE is a high-performance synthetic polymer, most famously known by the brand name Teflon. It is prized for a set of properties that make it uniquely suited for industrial applications.

The Key Properties Driving Adoption

Self-Lubrication and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means parts can move against each other with minimal resistance and wear.

This self-lubricating nature is critical in applications where lubricants are undesirable, such as in food processing or medical devices, or in hard-to-maintain equipment.

Extreme Chemical Inertness

PTFE is virtually inert, meaning it does not react with most chemicals, acids, and bases.

This makes it an ideal choice for components used in chemical processing, oil and gas, and pharmaceutical manufacturing, where exposure to corrosive substances is common.

High-Temperature Stability

PTFE bushings maintain their integrity and performance across a wide range of temperatures.

They can operate effectively in high-heat environments like automotive engines, aerospace components, and industrial machinery where other plastics would melt or degrade.

Regulatory Compliance

For industries like food, medical, and pharmaceuticals, materials must meet strict safety and purity standards.

PTFE is often compliant with these regulations (e.g., FDA standards for food contact), making it a safe and pre-approved choice for these sensitive applications.

Electrical Insulation

PTFE is an excellent electrical insulator, which leads to its use in electronics and electrical equipment to prevent short circuits and ensure reliable performance.

A Cross-Industry Breakdown of Applications

Food, Medical, and Pharmaceuticals

In these industries, hygiene and non-toxicity are paramount. PTFE's self-lubricating properties eliminate the need for potentially contaminating greases, and its inert nature ensures it won't react with products or human tissue.

Automotive and Aerospace

Engineers in these fields rely on PTFE for components in high-temperature and high-stress environments. Its low-friction properties improve efficiency and wear resistance in seals, gaskets, and bearing surfaces.

Chemical, Oil & Gas, and Power Generation

The ability of PTFE to withstand corrosive chemicals and extreme temperatures makes it essential for valves, seals, and linings in plants and pipelines, preventing leaks and equipment failure.

Understanding the Trade-offs

Relatively Low Mechanical Strength

While durable, pure PTFE is a relatively soft material. It can deform or "creep" under very high mechanical loads, a factor that engineers must account for during design.

Higher Cost

Compared to more common plastics like nylon or acetal, PTFE can be more expensive. Its selection is typically justified by performance requirements that other materials cannot meet.

When to Choose a PTFE Bushing

- If your primary focus is cleanliness or regulatory compliance: PTFE is ideal for food, medical, or pharmaceutical equipment where external lubricants are forbidden.

- If your primary focus is a harsh chemical or high-temperature environment: PTFE’s inertness and stability make it the default choice for chemical processing, aerospace, and industrial machinery.

- If your primary focus is maintenance-free, low-friction movement: PTFE simplifies mechanical design by providing smooth operation without the need for an external lubrication system.

Ultimately, a PTFE bushing is chosen when a component must perform reliably in an environment that is too hot, too corrosive, or too clean for conventional materials.

Summary Table:

| Industry | Primary Reason for PTFE Bushing Use | Key PTFE Property Utilized |

|---|---|---|

| Food & Medical | Hygiene, non-toxicity, regulatory compliance | Self-lubrication, chemical inertness |

| Aerospace & Automotive | High-temperature stability, low friction | High-temperature stability, self-lubrication |

| Chemical & Oil & Gas | Corrosion resistance, extreme temperature tolerance | Extreme chemical inertness, thermal stability |

| Electronics & Power Generation | Electrical insulation, reliability | Excellent electrical insulation |

Need High-Performance PTFE Components for Your Demanding Application?

At KINTEK, we specialize in manufacturing precision PTFE components—including bushings, seals, liners, and custom labware—for the most challenging environments in semiconductor, medical, laboratory, and industrial sectors.

Why Choose KINTEK?

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

- Material Expertise: Deep knowledge of PTFE properties ensures optimal performance for your unique operational conditions.

- Precision Production: We prioritize accuracy and durability to meet stringent industry standards.

Let us help you solve your toughest engineering challenges. Contact our team today to discuss your PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability