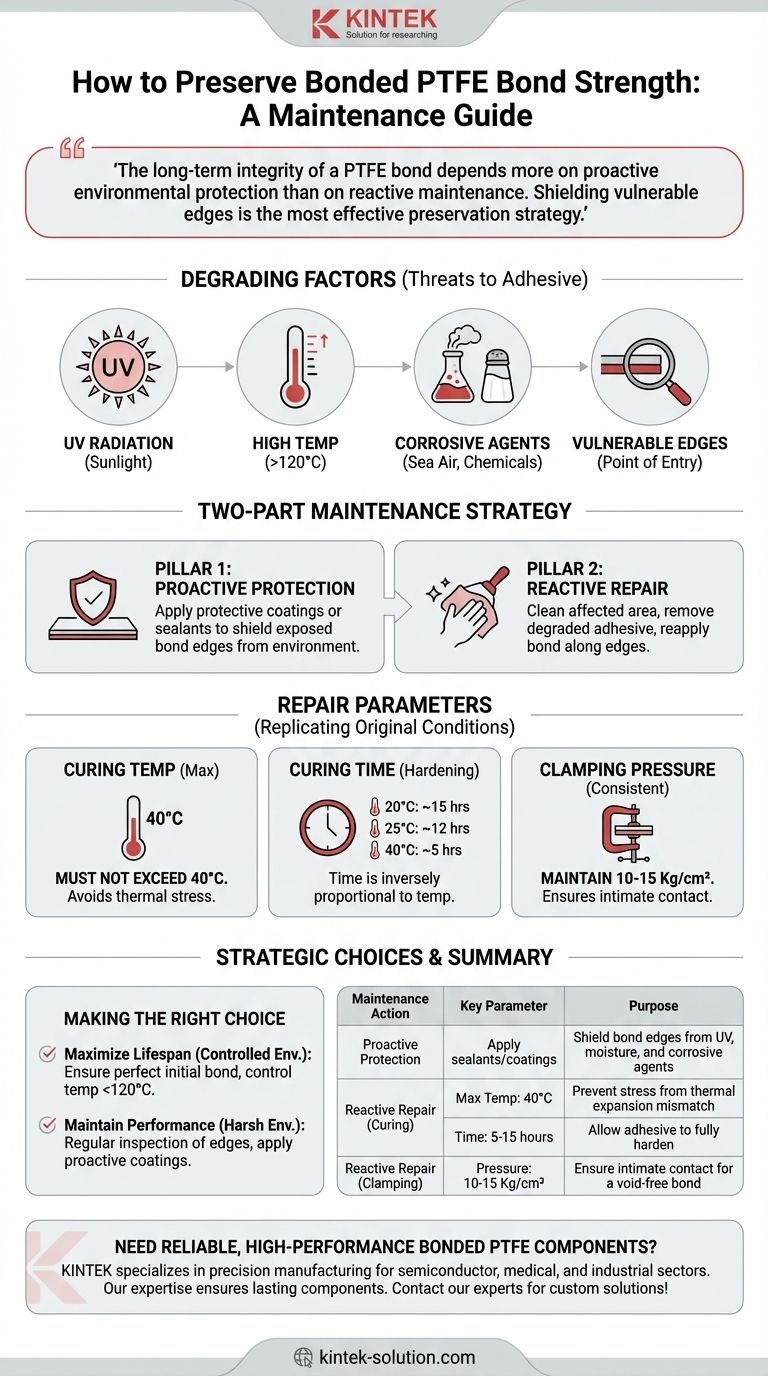

To maintain bonded PTFE, you must protect it from adverse environmental factors and perform targeted edge repairs when necessary. The primary threats to bond strength are excessive heat (above 120°C), UV radiation from sunlight, and corrosive elements like sea air or chemical fumes.

The long-term integrity of a PTFE bond depends more on proactive environmental protection than on reactive maintenance. Because degradation typically starts at the exposed edges, shielding these vulnerable areas is the most effective preservation strategy.

Key Factors That Degrade PTFE Bonds

Understanding what weakens the bond is the first step toward effective maintenance. The adhesive layer, not the PTFE itself, is typically the point of failure.

Environmental Exposure

Continuous exposure to the elements is the primary enemy of a strong PTFE bond. Sunlight (UV radiation) can break down the chemical structure of many adhesives over time.

High Temperatures

Temperatures exceeding 120°C can compromise the bond's integrity. This is a critical operational limit to respect for any bonded PTFE assembly.

Corrosive Agents

Chemicals in the air can initiate a corrosive attack on the adhesive. Common culprits include sea air (salt spray) and industrial chemical fumes, which can slowly eat away at the bond.

The Vulnerability of Bond Edges

Degradation almost always begins at the exposed edges of the bond line. This is where environmental factors have the easiest point of entry to attack the adhesive and begin the process of delamination.

A Two-Part Maintenance Strategy

Effective maintenance involves both preventing damage before it starts and correctly repairing it when it occurs.

Pillar 1: Proactive Protection

The most effective maintenance is preventative. Applying protective coatings or sealants over the exposed bond line can create a barrier against moisture, UV light, and corrosive agents.

This simple step shields the vulnerable edges of the bond from the environment, drastically extending its service life.

Pillar 2: Reactive Repair

If you notice the bond beginning to weaken at the edges, a targeted repair is necessary.

The process involves carefully cleaning the affected area to remove any contamination or degraded adhesive. Afterward, the bond must be reapplied along the cleaned edges, following strict procedural guidelines.

Understanding Repair Parameters

Repairing a bond is not a simple matter of applying more glue. To achieve a strong, lasting fix, you must replicate the conditions of the original bonding process.

Curing Temperature

The curing temperature for the adhesive must not exceed 40°C. This is because PTFE and the substrate it's bonded to have different coefficients of thermal expansion, and higher temperatures can induce stress that weakens the new bond as it sets.

Curing Time

Hardening time is inversely proportional to temperature. A repair will take approximately 15 hours to cure at 20°C, 12 hours at 25°C, or 5 hours at 40°C.

Clamping Pressure

During the entire curing (hardening) period, a consistent clamping pressure of 10-15 Kg/cm² must be maintained. This ensures intimate contact between the surfaces and a strong, void-free bond line.

Making the Right Choice for Your Goal

Your maintenance strategy should align with the component's operating environment.

- If your primary focus is maximizing lifespan in a controlled environment: Ensure the initial bond is perfect and strictly control operating temperatures below the 120°C limit.

- If your primary focus is maintaining performance in a harsh environment: Implement a regular inspection schedule focused on bond edges and proactively use protective coatings to seal them from corrosive elements.

Ultimately, preserving the strength of bonded PTFE is a matter of respecting its environmental limits and protecting its most vulnerable points.

Summary Table:

| Maintenance Action | Key Parameter | Purpose |

|---|---|---|

| Proactive Protection | Apply sealants/coatings | Shield bond edges from UV, moisture, and corrosive agents |

| Reactive Repair (Curing) | Max Temp: 40°C | Prevent stress from thermal expansion mismatch |

| Reactive Repair (Curing) | Time: 5-15 hours (20-40°C) | Allow adhesive to fully harden |

| Reactive Repair (Clamping) | Pressure: 10-15 Kg/cm² | Ensure intimate contact for a void-free bond |

Need reliable, high-performance bonded PTFE components? KINTEK specializes in the precision manufacturing of PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Our expertise ensures your components are built to last, even in demanding environments. Contact our experts today to discuss your specific application and receive a custom solution—from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key features of PTFE gaskets? Unlock Superior Chemical & Thermal Sealing

- What are the tensile strengths of PTFE and graphite packing? Choosing the Right Material for Your Application

- What are the aerospace and defense applications of PTFE? Essential for Extreme Reliability

- Why are PTFE rotary shaft seals preferred in aggressive media? Superior Chemical Resistance & Reliability

- What is the difference between PTFE valves and PFA valves? Choose the Right Fluoropolymer for Your System

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the key differences between monoaxial and multidirectional expanded PTFE? Choose the Right ePTFE for Your Seal

- What are the two main types of additives in PTFE-based materials? Reinforcements vs. Fillers Explained