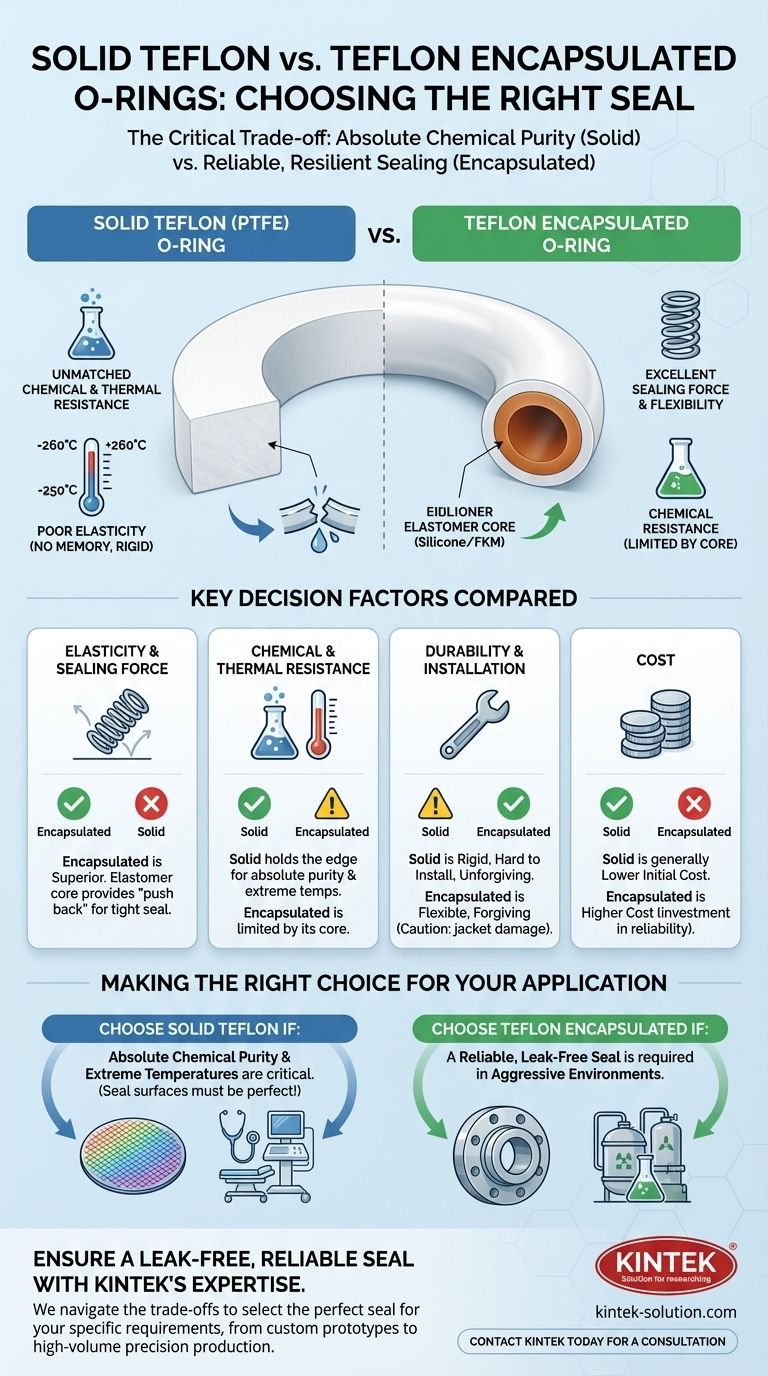

The choice between solid Teflon and Teflon encapsulated O-rings hinges on a critical engineering trade-off: chemical purity versus mechanical flexibility. Solid Teflon offers the highest resistance to chemicals and temperature but lacks the elasticity needed for a reliable seal. Teflon encapsulated O-rings combine a protective Teflon jacket with a flexible elastomer core, providing an excellent balance of chemical resistance and the sealing force required for most demanding applications.

The core decision comes down to this: Solid Teflon is for applications where absolute chemical inertness is non-negotiable and sealing force is a secondary concern, while encapsulated O-rings are for applications that demand both chemical resistance and a reliable, resilient seal.

Deconstructing the Sealing Options

To make an informed decision, you must first understand the fundamental construction and properties of each O-ring type. They are not interchangeable and are engineered to solve different problems.

Solid Teflon (PTFE) O-Rings

Solid Teflon O-rings are machined from pure Polytetrafluoroethylene (PTFE). This single-material composition is the source of both their greatest strengths and most significant weaknesses.

Their primary advantage is unmatched chemical and thermal resistance. They are virtually inert to all industrial chemicals and can operate in an exceptionally wide temperature range, from -250°C to +260°C.

They also possess a very low coefficient of friction, making them suitable for some dynamic applications where minimizing wear and drag is crucial.

However, their critical flaw is a lack of elasticity. Solid PTFE has no "memory" and does not spring back once compressed, which can easily lead to leaks if there are any surface imperfections or pressure fluctuations.

Teflon Encapsulated O-Rings

Encapsulated O-rings feature a hybrid design. They consist of an elastomer core (typically Silicone or FKM/Viton®) that is seamlessly enclosed within a thin Teflon jacket (FEP or PFA).

This construction provides the best of both worlds. The outer jacket delivers excellent chemical resistance, protecting the core from aggressive media.

The inner core provides the flexibility and resilience that solid Teflon lacks. This allows the O-ring to compress and maintain a constant sealing force, ensuring a reliable, leak-free connection in static and semi-dynamic applications.

Key Decision Factors Compared

Your choice will depend on which of the following properties is most critical for your specific application's success and long-term reliability.

Elasticity and Sealing Force

This is the most important differentiator. Encapsulated O-rings are far superior in this regard. The elastomer core provides the "push back" necessary to maintain a tight seal, even with minor imperfections in the sealing surfaces. Solid Teflon provides almost no sealing force on its own.

Chemical and Thermal Resistance

Solid Teflon O-rings hold the edge here, offering the absolute highest level of chemical inertness and the widest possible temperature range. While the Teflon jacket on an encapsulated ring is highly resistant, the overall performance is ultimately limited by the temperature constraints of the inner core material (e.g., Silicone or FKM).

Durability and Installation

The rigidity of solid Teflon O-rings can make installation difficult and risks damaging the ring if it must be stretched over a flange. Their lack of flexibility also makes them unforgiving of any scratches or flaws in the gland.

Encapsulated O-rings are more flexible and forgiving during installation. However, their thin Teflon jacket is susceptible to scratching or damage in abrasive environments, which could compromise the seal by exposing the inner core.

Cost

Due to their complex, multi-material construction, Teflon encapsulated O-rings are generally more expensive than their solid Teflon counterparts.

Understanding the Trade-offs

Choosing the wrong seal can lead to costly downtime and equipment failure. You must weigh the upfront cost against the long-term operational risks.

The True Cost of a Leak

While a solid Teflon O-ring may be cheaper initially, the cost of a leak caused by its poor elasticity can be catastrophic. The higher upfront cost of an encapsulated O-ring is often an investment in reliability and process safety.

The Purity vs. Reliability Dilemma

The choice is a classic engineering compromise. If your application demands absolute chemical purity and any elastomer contact is forbidden (e.g., in some semiconductor or pharmaceutical processes), solid Teflon is your only option. For nearly all other applications that require a robust seal in a harsh chemical environment, the encapsulated design is the more reliable choice.

Making the Right Choice for Your Application

Use these guidelines to determine the best fit for your operational goals.

- If your primary focus is absolute chemical purity and extreme temperatures: Choose a Solid Teflon O-ring, but ensure your hardware has perfectly machined sealing surfaces to compensate for the material's lack of elasticity.

- If your primary focus is a reliable, leak-free seal in a chemically aggressive environment: Choose a Teflon Encapsulated O-ring, as its flexible core provides the necessary sealing force that solid Teflon lacks.

- If your primary focus is cost reduction on a non-critical static seal: Carefully evaluate the risks. The higher upfront cost of an encapsulated ring is often cheaper than the downtime caused by a single leak from a solid ring.

Ultimately, your selection must be based on a clear understanding of your application's mechanical, chemical, and thermal demands.

Summary Table:

| Factor | Solid Teflon O-Ring | Teflon Encapsulated O-Ring |

|---|---|---|

| Chemical Resistance | Excellent (Unmatched) | Excellent (Limited by core) |

| Sealing Force / Elasticity | Poor (No memory) | Excellent (Flexible core) |

| Temperature Range | Very Wide (-250°C to +260°C) | Limited by elastomer core |

| Durability / Installation | Rigid, risk of damage | Flexible, more forgiving |

| Cost | Lower | Higher |

| Best For | Absolute purity, extreme temperatures | Reliable sealing in harsh environments |

Ensure a Leak-Free, Reliable Seal for Your Critical Application

Choosing the wrong O-ring can lead to costly downtime and equipment failure. Let KINTEK's expertise guide you to the optimal solution.

We manufacture precision PTFE components for the most demanding industries:

- Semiconductor & Medical: Where absolute purity and reliability are non-negotiable.

- Laboratory & Industrial: For harsh chemical environments that demand robust sealing.

Our value to you:

- Expert Guidance: We help you navigate the trade-offs between solid and encapsulated designs to select the perfect seal for your specific mechanical, chemical, and thermal requirements.

- Precision Production: From custom prototypes to high-volume orders, we deliver components that meet exact specifications for a perfect fit and reliable performance.

- Quality Assurance: Trust in seals that protect your processes and equipment, ensuring long-term operational safety and efficiency.

Don't compromise on your seal's performance. Contact KINTEK today for a consultation and let our specialists provide a solution tailored to your application's unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability