PTFE-lined bearings are exceptionally well-suited for suspension parts due to their unique combination of self-lubrication, extreme durability, and resistance to environmental contamination. Unlike traditional greased bearings that can attract and trap grit, a PTFE-lined bearing is self-wiping, ensuring consistent, low-friction performance in the harsh conditions faced by suspension components.

The core advantage of a PTFE-lined bearing in a suspension system is its ability to provide maintenance-free, predictable performance in environments where traditional lubricated joints would quickly degrade due to contamination from dirt, water, and road grime.

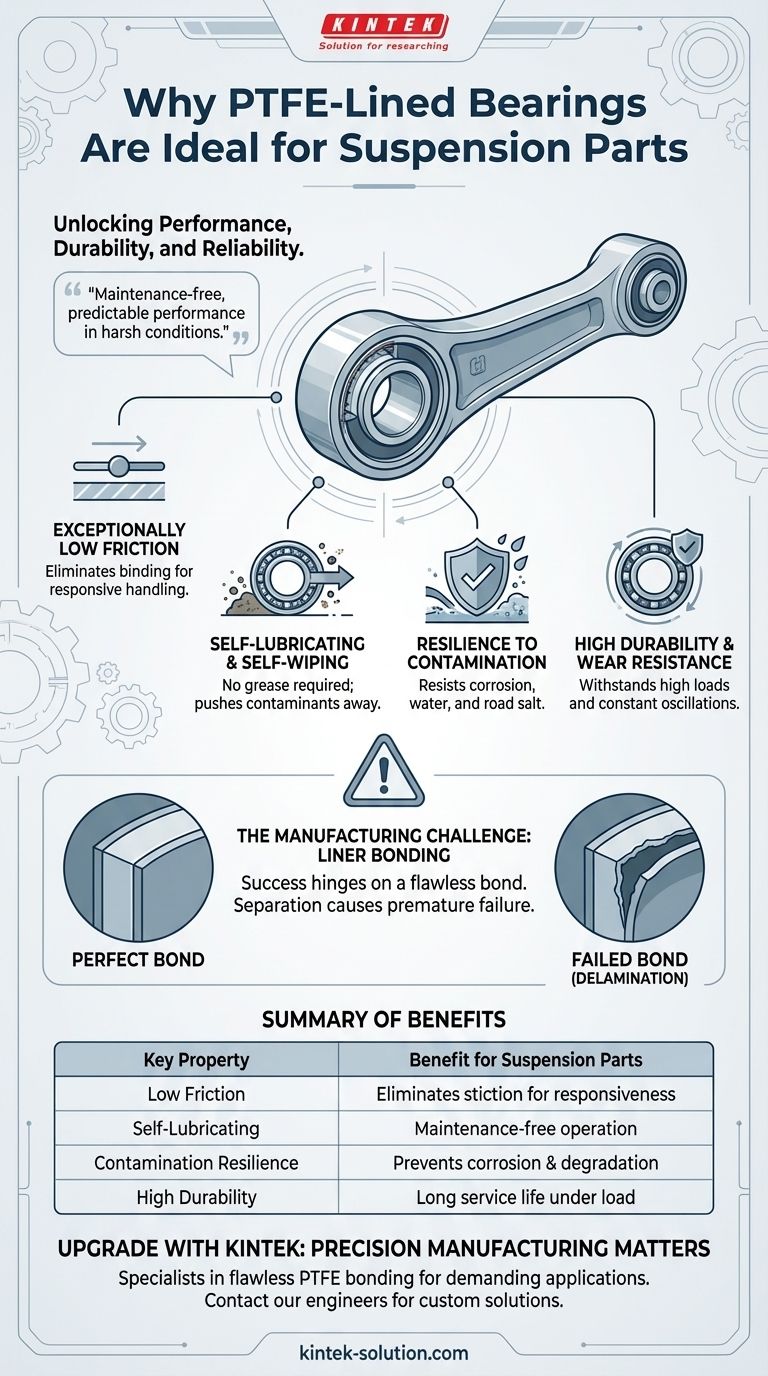

The Core Advantages in a High-Stress Environment

To understand why PTFE (polytetrafluoroethylene) is so effective, we must look at its fundamental material properties and how they address the primary challenges of a vehicle's suspension.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows suspension components to rotate and articulate smoothly without the binding or "stiction" that can occur with other materials. This translates directly to a more responsive and predictable suspension feel.

Self-Lubricating and Self-Wiping

The PTFE liner is the lubricant. It requires no external grease, which is a key advantage. Grease attracts and holds onto dirt and grit, which can form an abrasive paste that accelerates wear. Because PTFE-lined bearings are designed with no clearance, they are self-wiping, pushing contaminants away from the load-bearing surface.

Resilience to Contamination

Suspension components are constantly exposed to water, road salt, and dirt. PTFE is chemically inert and non-porous, making it highly resistant to moisture and chemicals. This prevents the corrosion and degradation that can plague conventional bearings.

High Durability and Wear Resistance

Despite its slick surface, PTFE is a very tough polymer. When woven into a fabric liner and bonded to a metal race, it can withstand the high loads and constant, small-angle oscillations characteristic of suspension movement, ensuring a long service life.

The Critical Importance of Manufacturing Quality

The exceptional benefits of PTFE come with a significant engineering challenge that cannot be overlooked. The success or failure of the entire bearing hinges on one critical factor: the quality of the liner's bond to the bearing race.

The Risk of Liner Separation

The single greatest point of failure for a PTFE-lined bearing is the separation, or "delamination," of the liner from its backing. Once the liner separates, the bearing degrades with extreme speed.

Why Bonding Is Difficult

PTFE is famous for its non-stick properties. While excellent for performance, this same property makes it inherently difficult to bond securely to other materials. This process requires extensive knowledge and highly controlled manufacturing techniques.

Consequences of a Failed Bond

If the liner separates, it will quickly tear and bunch up, causing a dramatic increase in friction and play within the joint. In a critical suspension component, this can lead to poor handling, noise, and potentially catastrophic failure of the part.

The Need for a Proven Manufacturer

It is imperative to select a manufacturer with extensive, proven experience in bonding PTFE liners for high-stress applications. An improperly bonded bearing from a low-quality source presents a significant reliability and safety risk.

Making the Right Choice for Your Application

Selecting the right component is about matching its properties to your primary goal.

- If your primary focus is maximum performance: PTFE offers the lowest friction possible, eliminating suspension bind and allowing for the most responsive and predictable vehicle handling.

- If your primary focus is longevity in harsh conditions: The self-wiping and contaminant-resistant nature of PTFE makes it the superior choice for off-road or daily-driven vehicles exposed to dirt, rain, and road salt.

- If your primary focus is safety and reliability: The benefits of PTFE are only realized when sourced from a high-quality manufacturer with documented expertise in liner bonding to prevent premature failure.

By understanding both the material's inherent strengths and its manufacturing dependencies, you can confidently leverage PTFE-lined bearings to build a more robust and responsive suspension system.

Summary Table:

| Key Property | Benefit for Suspension Parts |

|---|---|

| Exceptionally Low Friction | Eliminates binding/stiction for responsive handling |

| Self-Lubricating & Self-Wiping | Maintenance-free operation; pushes contaminants away |

| Resilience to Contamination | Resists water, road salt, and dirt, preventing corrosion |

| High Durability & Wear Resistance | Withstands high loads and constant oscillations for long service life |

Upgrade your suspension system with reliable, high-performance PTFE components from KINTEK.

As specialists in precision PTFE manufacturing for demanding industries like automotive and industrial equipment, we understand the critical importance of a flawless bond between the PTFE liner and bearing race. Our custom fabrication process, from prototypes to high-volume orders, ensures your PTFE-lined bearings deliver on their promise of maintenance-free operation, contamination resistance, and long-term durability—without the risk of premature failure.

Let us help you build a safer, more responsive vehicle. Contact our engineering team today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability