In short, expanded Polytetrafluoroethylene (ePTFE) sheets are used for gaskets because they provide an exceptionally reliable seal across a vast range of demanding conditions. They combine the near-universal chemical resistance and temperature stability of standard PTFE with superior mechanical properties, effectively solving PTFE's primary weakness of material creep or "cold flow." This makes ePTFE a highly versatile and durable solution for critical sealing applications.

The core advantage of ePTFE is that it delivers the chemical inertness of PTFE while adding crucial mechanical stability. This resistance to cold flow ensures a long-lasting, tight seal under fluctuating pressures and temperatures where other materials, including standard PTFE, might fail.

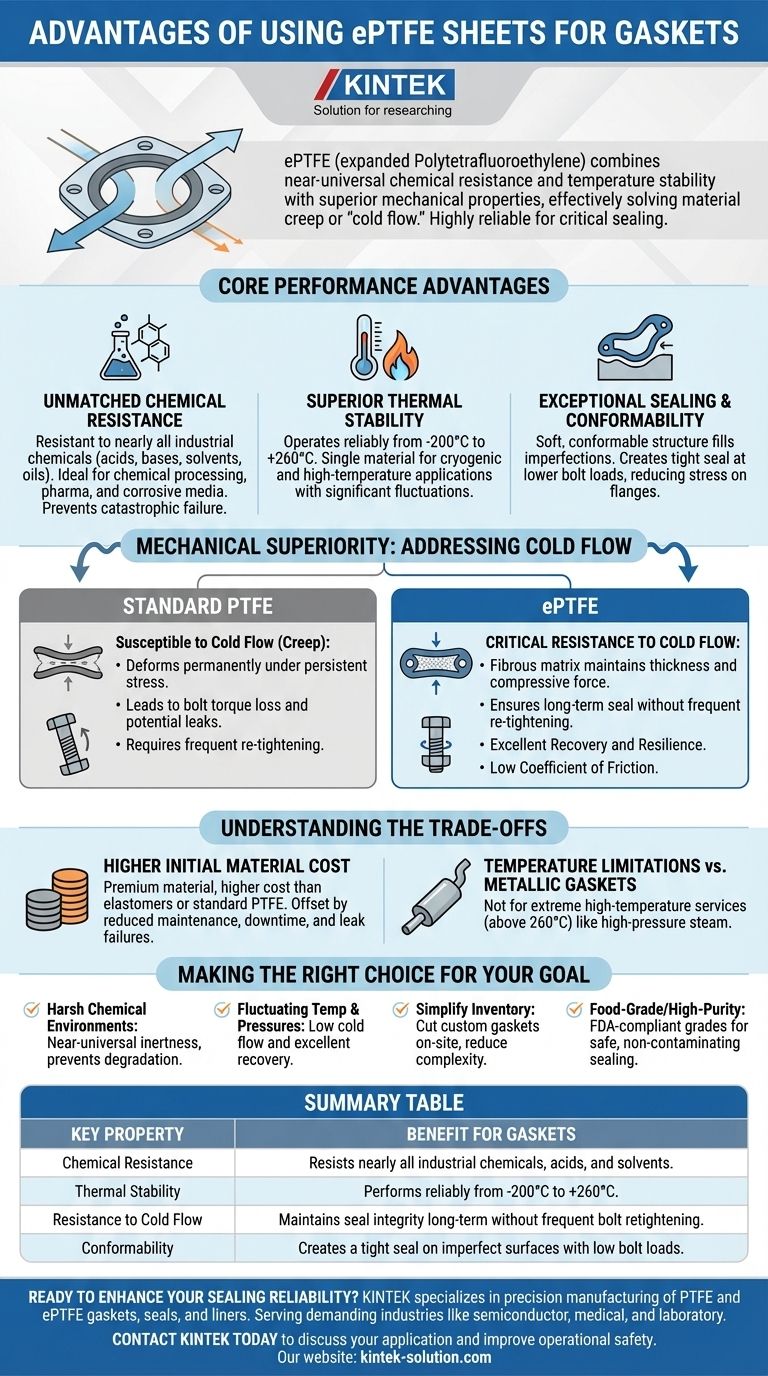

Unpacking the Core Performance Advantages

To understand why ePTFE is a premier gasketing material, we must look at its fundamental chemical, thermal, and mechanical characteristics.

Unmatched Chemical Resistance

ePTFE inherits the exceptional chemical inertness of Polytetrafluoroethylene. It is resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, oils, and hydrocarbons.

This makes it an ideal choice for chemical processing, pharmaceuticals, and any application involving corrosive media where gasket degradation could lead to catastrophic failure.

Superior Thermal Stability

The material demonstrates remarkable stability across a very wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used reliably in applications involving cryogenic fluids as well as high-temperature processes, providing a single material solution for systems with significant temperature fluctuations.

Exceptional Sealing and Conformability

The "expanded" nature of ePTFE gives it a soft, conformable structure. This allows the gasket to easily fill imperfections, scratches, and minor warping on flange surfaces.

This results in an extremely tight seal at lower bolt loads, reducing stress on flanges and equipment, especially on delicate or non-metallic flanges (e.g., glass-lined steel).

The Mechanical Superiority of ePTFE

The expansion process transforms standard PTFE into a material with a multidirectional fibrous structure. This is what gives ePTFE its significant mechanical advantages, addressing the primary shortcoming of virgin PTFE.

Critical Resistance to Cold Flow (Creep)

Cold flow, or creep, is the tendency of a solid material to deform permanently under persistent stress. Standard PTFE is highly susceptible to this, causing the gasket to thin out over time, which leads to a loss of bolt torque and potential leaks.

ePTFE's fibrous matrix provides excellent resistance to cold flow. The gasket maintains its thickness and compressive force, ensuring a reliable, long-term seal without the need for frequent re-tightening of bolts.

Excellent Recovery and Resilience

This resistance to creep also gives ePTFE excellent recovery properties. It can adapt to changing pressures and thermal cycles without losing its sealing integrity.

This makes it exceptionally well-suited for dynamic applications where pressure and temperature are not constant, as it can expand and contract with the flanges while maintaining a tight seal.

Low Coefficient of Friction

Like all PTFE, ePTFE has an extremely low coefficient of friction. This "non-stick" property makes gaskets easy to remove from flange surfaces without residue, simplifying maintenance and cleanup.

Understanding the Trade-offs

While ePTFE is a high-performance material, no solution is perfect for every scenario. Acknowledging its limitations is key to making an informed decision.

Higher Initial Material Cost

ePTFE is a premium material, and its initial cost is typically higher than that of common elastomers (like rubber) or standard PTFE gaskets.

This cost must be weighed against the total cost of ownership. The reduction in maintenance, downtime, and potential leak-related failures often provides a strong return on the initial investment.

Temperature Limitations vs. Metallic Gaskets

While its temperature range is excellent for a polymer, it cannot compete with metallic or semi-metallic gaskets (like spiral wound gaskets) in extreme high-temperature services, such as high-pressure steam or exhaust systems that operate well above 260°C (500°F).

Not a "One-Size-Fits-All" Solution

Despite its versatility, the specific grade of ePTFE and its suitability for the application's pressure, temperature, and media must be verified. Different densities and structures are manufactured for different purposes. Always consult manufacturer specifications for your specific operating conditions.

Making the Right Choice for Your Goal

The decision to use ePTFE should be driven by the specific demands of your application.

- If your primary focus is reliability in harsh chemical environments: ePTFE is an ideal choice due to its near-universal chemical inertness, preventing gasket degradation and ensuring process purity.

- If your primary focus is maintaining a seal under fluctuating temperatures and pressures: The low cold flow and excellent recovery of ePTFE make it superior to standard PTFE for dynamic conditions.

- If your primary focus is simplifying inventory and maintenance: The ability to cut custom gaskets from ePTFE sheets on-site significantly reduces operational complexity, lead times, and warehousing costs.

- If your primary focus is food-grade or high-purity applications: Choose an FDA-compliant grade of ePTFE for a safe, non-contaminating, and non-stick sealing solution that simplifies cleaning.

Ultimately, choosing ePTFE is an investment in long-term operational reliability and safety.

Summary Table:

| Key Property | Benefit for Gaskets |

|---|---|

| Chemical Resistance | Resists nearly all industrial chemicals, acids, and solvents. |

| Thermal Stability | Performs reliably from -200°C to +260°C. |

| Resistance to Cold Flow | Maintains seal integrity long-term without frequent bolt retightening. |

| Conformability | Creates a tight seal on imperfect surfaces with low bolt loads. |

Ready to enhance your sealing reliability with high-performance ePTFE gaskets?

KINTEK specializes in the precision manufacturing of PTFE and ePTFE components, including custom gaskets, seals, and liners. We serve demanding industries like semiconductor, medical, and laboratory, where material performance is critical. Our expertise ensures you get a solution tailored to your specific chemical, temperature, and pressure requirements—from prototypes to high-volume production.

Contact KINTEK today to discuss your application and discover how our ePTFE solutions can improve your operational safety and reduce maintenance costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What environmental conditions were studied for PTFE sliding rubber bearing corrosion? Simulate Decades of Harsh Exposure

- How do PTFE envelope gaskets perform in corrosive environments? Achieve Superior Chemical Resistance

- What are the features and applications of PTFE lip gaskets? A Guide to Sealing in Extreme Environments

- Which substances is PTFE not chemically resistive to? Avoid These Extreme Conditions

- What are some standard sizes available for PTFE washers? Find the Perfect Fit for Your Application

- What non-standard options are available for PTFE slide bearings? Customize for Temperature, Load, and Movement

- What are the compression and rebound characteristics of ePTFE gaskets? Master Sealing for Demanding Flanges

- How have gland packing materials evolved over time? From Natural Fibers to High-Performance Synthetics