At its core, a PTFE lip gasket is a specialized sealing component designed for challenging environments where both physical constraints and material resilience are critical. Its effectiveness comes from combining the unique physical shape of a "lip" seal—a thin cross-section with a thick, flexible lip—with the exceptional properties of Polytetrafluoroethylene (PTFE) plastic.

The primary advantage of a PTFE lip gasket lies in its dual capability: the lip design creates a tight, effective seal in space-constrained or irregular applications with minimal force, while the PTFE material provides unmatched resistance to chemicals, temperature extremes, and contamination.

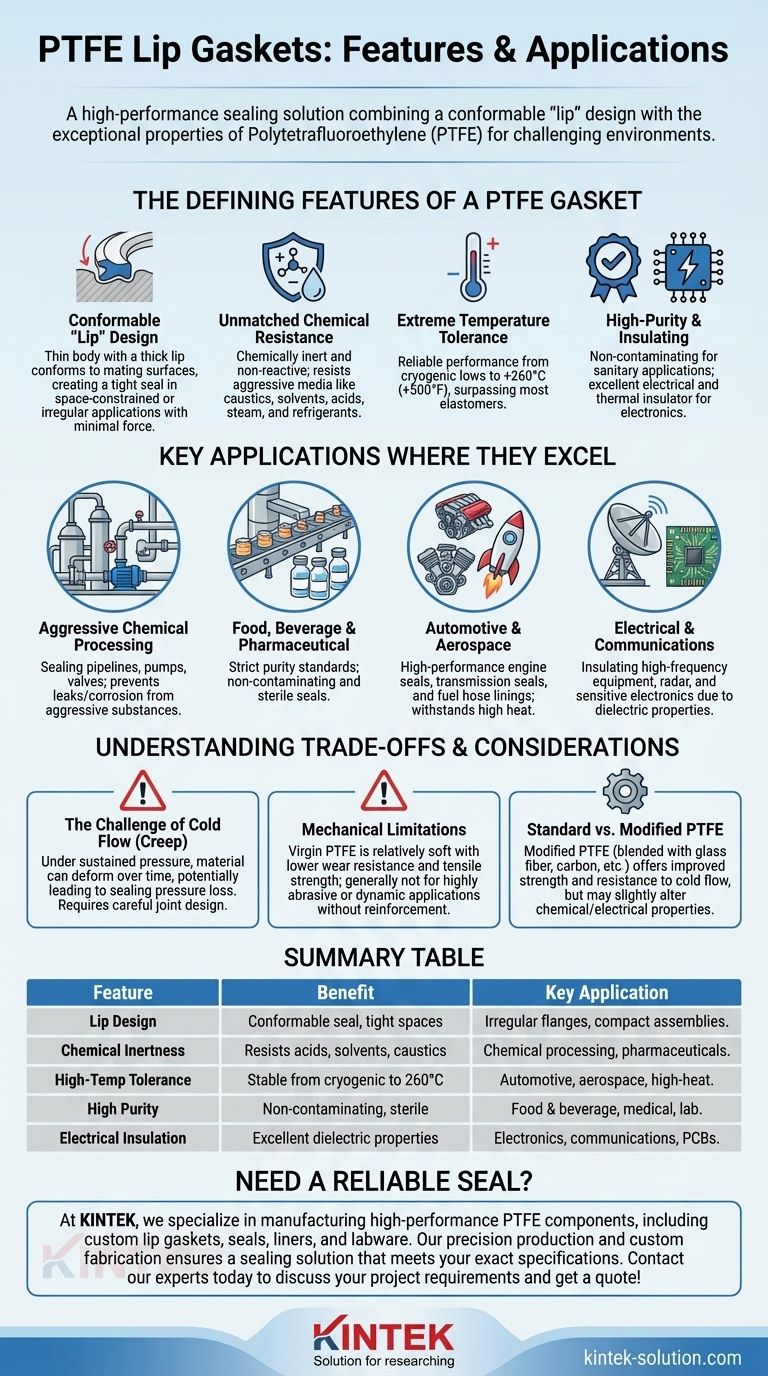

The Defining Features of a PTFE Gasket

To understand where these gaskets excel, we must first look at the distinct benefits offered by their material and their design.

The "Lip" Design for Conformable Sealing

The term "lip gasket" refers to its physical profile. A thin body with a thicker, protruding lip allows the seal to flex and conform to mating surfaces.

This design creates a highly effective seal when compressed, making it ideal for applications with tight space limitations or where flange surfaces may not be perfectly flat.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert plastics available. It is non-reactive and does not corrode.

This makes it the material of choice for sealing aggressive media such as caustic chemicals, hydrocarbons, strong acids, solvents, steam, and refrigerants.

Extreme Temperature Tolerance

PTFE gaskets perform reliably across an exceptionally wide temperature range.

They maintain their integrity and sealing capability in conditions from cryogenic lows up to +260°C (+500°F), far surpassing the limits of most common elastomers.

High-Purity and Insulating Properties

In its virgin form, PTFE is non-contaminating, odorless, and non-wetting, making it perfect for sanitary applications.

Furthermore, it is an excellent electrical and thermal insulator, used to protect sensitive electronic components like printed circuit boards.

Where PTFE Lip Gaskets Excel: Key Applications

The combination of these features makes PTFE lip gaskets a problem-solver across numerous demanding industries.

Aggressive Chemical Processing

Due to their chemical inertness, these gaskets are widely used in chemical plants for sealing pipelines, pumps, valves, and vessels. They prevent leaks and corrosion when handling highly aggressive substances.

Food, Beverage, and Pharmaceutical

The non-contaminating and non-reactive nature of PTFE is critical for industries with strict purity standards. These gaskets ensure that the product remains sterile and untainted.

Automotive and Aerospace

In high-performance applications, PTFE is used for engine oil seals, transmission fluid seals, and fuel hose linings. Its ability to withstand high heat makes it a superior replacement for materials like polyethylene in aerospace and computer components.

Electrical and Communications

The outstanding dielectric properties of PTFE make it a primary choice for insulating high-frequency communication equipment, radar systems, and other sensitive electronics.

Understanding the Trade-offs and Considerations

While incredibly versatile, PTFE is not the solution for every sealing challenge. An objective assessment requires understanding its limitations.

The Challenge of Cold Flow (Creep)

The most significant characteristic to manage with PTFE is cold flow, or creep. Under sustained pressure (like the bolt load on a flange), the material can slowly deform over time.

This can lead to a loss of sealing pressure and potential leaks if not accounted for in the joint design. This is particularly relevant in high-pressure or high-temperature applications.

Mechanical Limitations

Standard, or "virgin," PTFE is a relatively soft material. While its flexibility is an asset for sealing, it has lower wear resistance and tensile strength compared to other engineering plastics or metals.

It is generally not suited for highly abrasive or dynamic sealing applications without reinforcement.

Standard vs. Modified PTFE

To overcome these mechanical limitations, PTFE is often blended with fillers like glass fiber, carbon, or bronze. This modified PTFE offers significantly improved strength and resistance to cold flow.

However, be aware that adding fillers can sometimes slightly reduce the overall chemical resistance or change the electrical properties of the material.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its capabilities to your primary engineering goal.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: PTFE's inherent material properties make it one of the best and safest choices available.

- If your primary focus is sealing within a tight space or on an uneven surface: The conformable nature of the lip gasket design provides a reliable seal with minimal compression force.

- If your primary focus is a high-pressure joint or a dynamic seal: You must account for cold flow and wear by considering a modified (filled) PTFE or another class of sealing material entirely.

Ultimately, a PTFE lip gasket is a high-performance solution for when both the physical environment and the chemical media are too demanding for conventional seals.

Summary Table:

| Feature | Benefit | Key Application |

|---|---|---|

| Lip Design | Conformable seal in tight spaces | Irregular flanges, compact assemblies |

| Chemical Inertness | Resists acids, solvents, caustics | Chemical processing, pharmaceuticals |

| High-Temp Tolerance | Stable from cryogenic to 260°C (500°F) | Automotive, aerospace, high-heat processes |

| High Purity | Non-contaminating, sterile | Food & beverage, medical, laboratory |

| Electrical Insulation | Excellent dielectric properties | Electronics, communications, PCBs |

Need a reliable seal for a demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom lip gaskets, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a sealing solution that meets your exact specifications for chemical resistance, temperature stability, and purity.

Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection