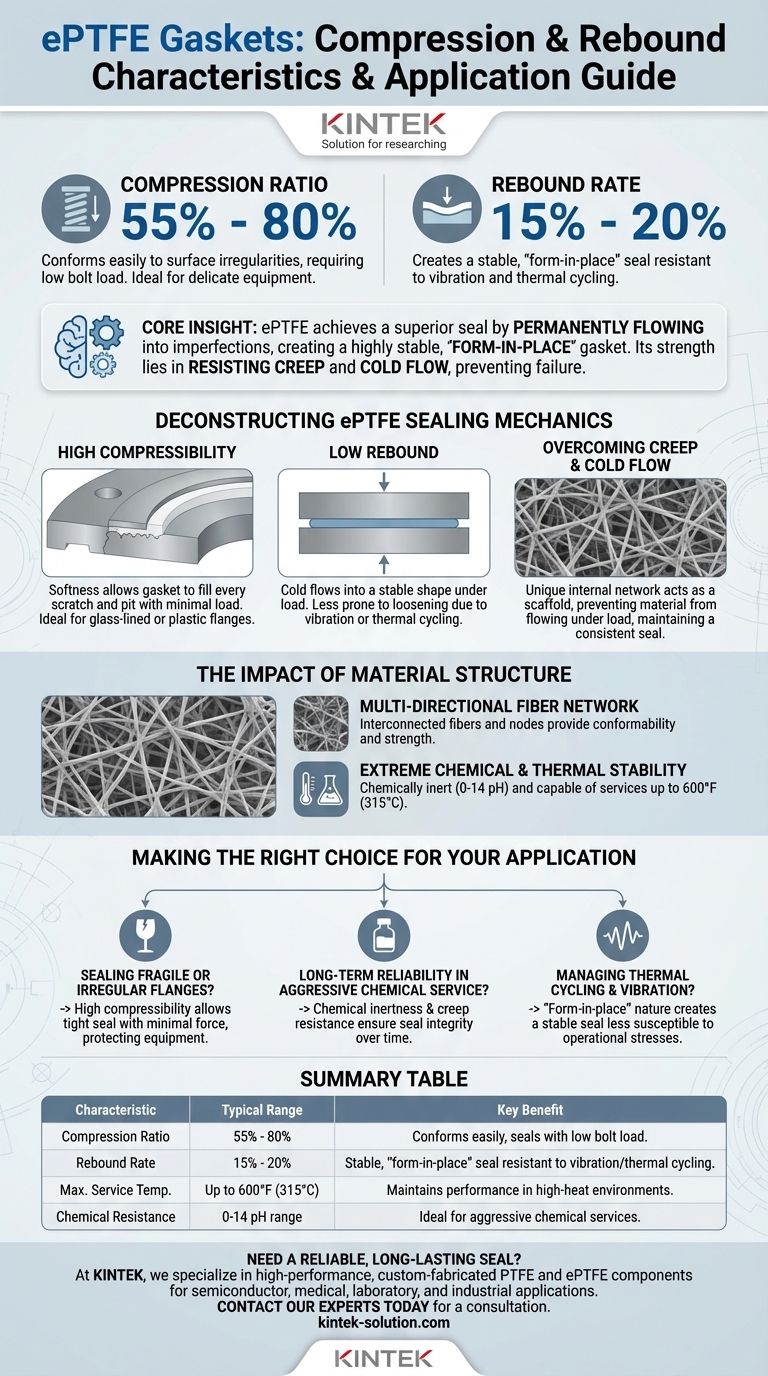

To be clear, Expanded Polytetrafluoroethylene (ePTFE) gaskets are characterized by very high compressibility and relatively low rebound. They exhibit a compression ratio between 55% and 80%, allowing them to conform easily to surface irregularities, while their rebound rate is typically only 15% to 20% when under load.

The core insight is that ePTFE creates a superior seal not through elastic memory like rubber, but by permanently flowing into imperfections to create a highly stable, "form-in-place" gasket. Its true strength lies in resisting the creep and cold flow that typically cause other PTFE materials to fail over time.

Deconstructing ePTFE Sealing Mechanics

Understanding the numbers is only the first step. The real value comes from knowing how these distinct properties work together to create an exceptionally reliable static seal, especially in demanding industrial environments.

High Compressibility: The Key to an Initial Seal

The standout feature of ePTFE is its softness, reflected in its 55% to 80% compression ratio.

This extreme conformability allows the gasket to fill every scratch, pit, and irregularity on a flange face with minimal bolt load. This makes it an ideal choice for delicate or easily damaged equipment, such as glass-lined or plastic flanges.

Low Rebound: Creating a Stable, Set Seal

A rebound rate of only 15% to 20% might seem low, but it is fundamental to how ePTFE functions.

Unlike an elastomer that constantly pushes back, ePTFE cold flows into a stable shape under compression. This low rebound signifies that the material is not storing significant elastic energy, resulting in a seal that is less prone to loosening due to vibration or thermal cycling.

Overcoming Creep and Cold Flow

The primary failure mode for standard solid PTFE gaskets is creep, or cold flow, where the material slowly extrudes out from under the flange load, causing bolt tension and sealing pressure to be lost.

The unique, multi-directional fibrous structure of ePTFE fundamentally solves this problem. This internal network acts like a scaffold, providing exceptional toughness and preventing the material from flowing, thus maintaining a consistent seal over a very long service life.

The Impact of Material Structure

The performance characteristics of ePTFE are a direct result of its unique manufacturing process and resulting physical structure.

The Multi-Directional Fiber Network

The expansion process creates a microscopic web of interconnected PTFE fibers and nodes. This structure gives the material its softness and conformability while providing the strength to resist being squeezed out of the joint.

Extreme Chemical and Thermal Stability

As a pure PTFE material, ePTFE retains its parent polymer's extraordinary resilience.

It is chemically inert across the entire 0-14 pH range, with the only notable exceptions being molten alkali metals and elemental fluorine. It also maintains its properties across a wide operational temperature range, capable of handling services up to 600°F (315°C).

Understanding the Trade-offs and Application Limits

No material is perfect for every situation. Being objective about ePTFE's limitations is key to using it successfully.

Rebound is Not Dynamic Recovery

The low rebound means ePTFE is designed for static applications. It is not suitable for joints that are frequently opened and closed or for applications that require a gasket to perform repeated dynamic sealing cycles.

Pressure Ratings are System-Dependent

While capable of sealing pressures over 3000 psi, this rating is highly dependent on the flange design, surface finish, bolt load, and the media being sealed. The maximum pressure for any given application must be calculated based on the entire joint system.

Not a "One-Size-Fits-All" Solution

Despite its versatility, the softness of ePTFE means it may not be the primary choice for extremely high-pressure applications where a rigid, high-strength gasket like a spiral wound or ring type joint is specified by design codes.

Making the Right Choice for Your Application

Use these guidelines to determine if ePTFE's unique profile fits your specific goal.

- If your primary focus is sealing fragile or irregular flanges: The high compressibility of ePTFE allows it to achieve a tight seal with minimal compressive force, protecting your equipment.

- If your primary focus is long-term reliability in aggressive chemical service: The combination of chemical inertness and exceptional creep resistance makes ePTFE a premier choice for maintaining seal integrity over time.

- If your primary focus is managing thermal cycling and vibration: The "form-in-place" nature of ePTFE creates a stable seal that is less susceptible to loosening from operational stresses than traditional gaskets.

By understanding these properties, you can confidently specify ePTFE for creating exceptionally stable and durable static seals in your most critical applications.

Summary Table:

| Characteristic | Typical Range | Key Benefit |

|---|---|---|

| Compression Ratio | 55% - 80% | Conforms easily to surface irregularities, seals with low bolt load. |

| Rebound Rate | 15% - 20% | Creates a stable, "form-in-place" seal resistant to vibration and thermal cycling. |

| Max. Service Temperature | Up to 600°F (315°C) | Maintains performance in high-heat environments. |

| Chemical Resistance | 0-14 pH range | Ideal for aggressive chemical services. |

Need a reliable, long-lasting seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance, custom-fabricated PTFE and ePTFE components. Our expertise ensures your gaskets provide the precise compression and stability required for success in semiconductor, medical, laboratory, and industrial applications.

Let's solve your sealing challenge together. Contact our experts today for a consultation on custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of using PTFE impellers despite their manufacturing challenges? Unlock Superior Performance in Harsh Conditions

- What makes PTFE expansion bellows durable and long-lasting? Unmatched Chemical & Thermal Resistance

- What makes ePTFE sheets a preferred material in the food, beverage, and pharmaceutical sectors? Ensuring Product Purity and Safety

- What are the types of PTFE expansion joints available? Find the Right Fit for Your Piping System

- What are POT-PTFE bearings, and how do they function? Manage Massive Loads with Precision Movement

- What industries benefit most from PTFE coatings? Unlock Superior Performance in Demanding Environments

- How do PTFE gaskets perform under extreme temperatures? Unlock Reliable Sealing from -200°C to +260°C

- How do fillers improve the properties of PTFE? Boost Wear Resistance, Creep Resistance & Thermal Conductivity