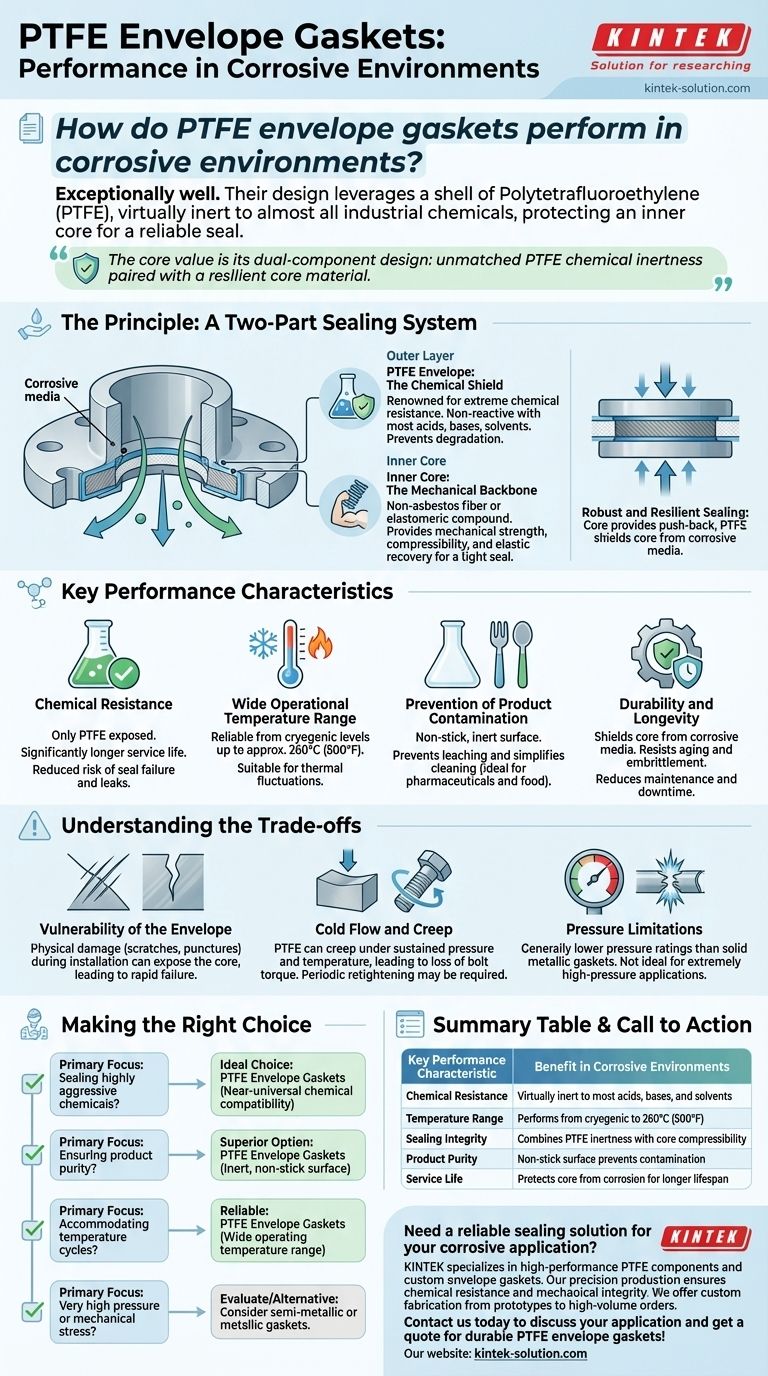

In corrosive environments, PTFE envelope gaskets perform exceptionally well. Their design leverages a shell of Polytetrafluoroethylene (PTFE), a material that is virtually inert to almost all industrial chemicals. This PTFE "envelope" acts as a protective shield for an inner core material, combining near-universal chemical resistance with the mechanical properties needed for a reliable seal.

The core value of a PTFE envelope gasket is its dual-component design. It successfully pairs the unmatched chemical inertness of a PTFE shell with the superior compressibility and resilience of a separate core material, creating a robust seal for aggressive media where a single material would fail.

The Principle: A Two-Part Sealing System

To understand their performance, you must see PTFE envelope gaskets not as a single material, but as a composite system designed for a specific purpose.

The PTFE Envelope: The Chemical Shield

The outer layer, or envelope, is made of PTFE. This material is renowned for its extreme chemical resistance.

It is non-reactive with most acids, bases, solvents, and other corrosive agents, preventing the gasket itself from degrading or corroding when in contact with the process fluid.

The Inner Core: The Mechanical Backbone

Inside the envelope is a core material, often a non-asbestos fiber or an elastomeric compound. This core provides the gasket's mechanical strength.

It delivers the compressibility and elastic recovery required to conform to flange imperfections and maintain a tight seal under pressure, properties that solid PTFE lacks on its own.

The Result: Robust and Resilient Sealing

This combination allows the gasket to maintain its structural integrity and sealing force over time. The core provides the physical push-back, while the PTFE envelope ensures that corrosive media never reaches and attacks that core.

Key Performance Characteristics in Corrosive Service

The unique construction of PTFE envelope gaskets gives them several distinct advantages in demanding chemical applications.

Unmatched Chemical Resistance

Because the only surface exposed to the media is PTFE, the gasket is protected from chemical attack. This leads to a significantly longer service life and reduces the risk of seal failure and leaks in harsh environments.

Wide Operational Temperature Range

PTFE performs reliably across a vast temperature spectrum, from cryogenic levels up to approximately 260°C (500°F). This makes it suitable for processes with significant temperature fluctuations.

Prevention of Product Contamination

The non-stick and inert surface of PTFE is critical in industries like pharmaceuticals and food processing. It prevents gasket material from leaching into the product and simplifies cleaning by resisting material adhesion.

Durability and Longevity

By shielding the mechanically-focused core from corrosive media, the gasket resists the aging and embrittlement that would otherwise cause conventional gaskets to fail. This durability reduces maintenance frequency and downtime.

Understanding the Trade-offs

While highly effective, it's crucial to recognize the limitations inherent in the envelope design to ensure proper application.

Vulnerability of the Envelope

The primary weakness is the potential for physical damage to the PTFE envelope. If the envelope is scratched or punctured during installation, the inner core can be exposed to the corrosive media, leading to rapid failure.

Cold Flow and Creep

PTFE is a relatively soft material susceptible to "cold flow," or creep, under sustained pressure and temperature. This can lead to a loss of bolt torque over time, requiring periodic retightening to maintain a secure seal.

Pressure Limitations

While the core improves mechanical performance, PTFE envelope gaskets generally have lower pressure ratings than solid metallic or semi-metallic gaskets. They are not the ideal choice for extremely high-pressure applications.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your operational goals.

- If your primary focus is sealing highly aggressive chemicals: PTFE envelope gaskets are an ideal choice due to their near-universal chemical compatibility.

- If your primary focus is ensuring product purity: The inert, non-stick surface of the PTFE envelope makes it a superior option for food, beverage, and pharmaceutical processes.

- If your primary focus is accommodating temperature cycles: The gasket's wide operating temperature range provides reliability in systems with thermal fluctuations.

- If your primary focus is very high pressure or mechanical stress: You should evaluate whether the envelope's integrity can be maintained and consider a semi-metallic or metallic gasket as an alternative.

By understanding its composite design, you can confidently deploy the PTFE envelope gasket as a powerful solution for your most demanding sealing challenges.

Summary Table:

| Key Performance Characteristic | Benefit in Corrosive Environments |

|---|---|

| Chemical Resistance | Virtually inert to most acids, bases, and solvents |

| Temperature Range | Performs from cryogenic to 260°C (500°F) |

| Sealing Integrity | Combines PTFE inertness with core compressibility |

| Product Purity | Non-stick surface prevents contamination |

| Service Life | Protects core from corrosion for longer lifespan |

Need a reliable sealing solution for your corrosive application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets designed for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets provide the chemical resistance and mechanical integrity your processes demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and performance for your specific needs.

Contact us today to discuss your application and get a quote for durable PTFE envelope gaskets!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry