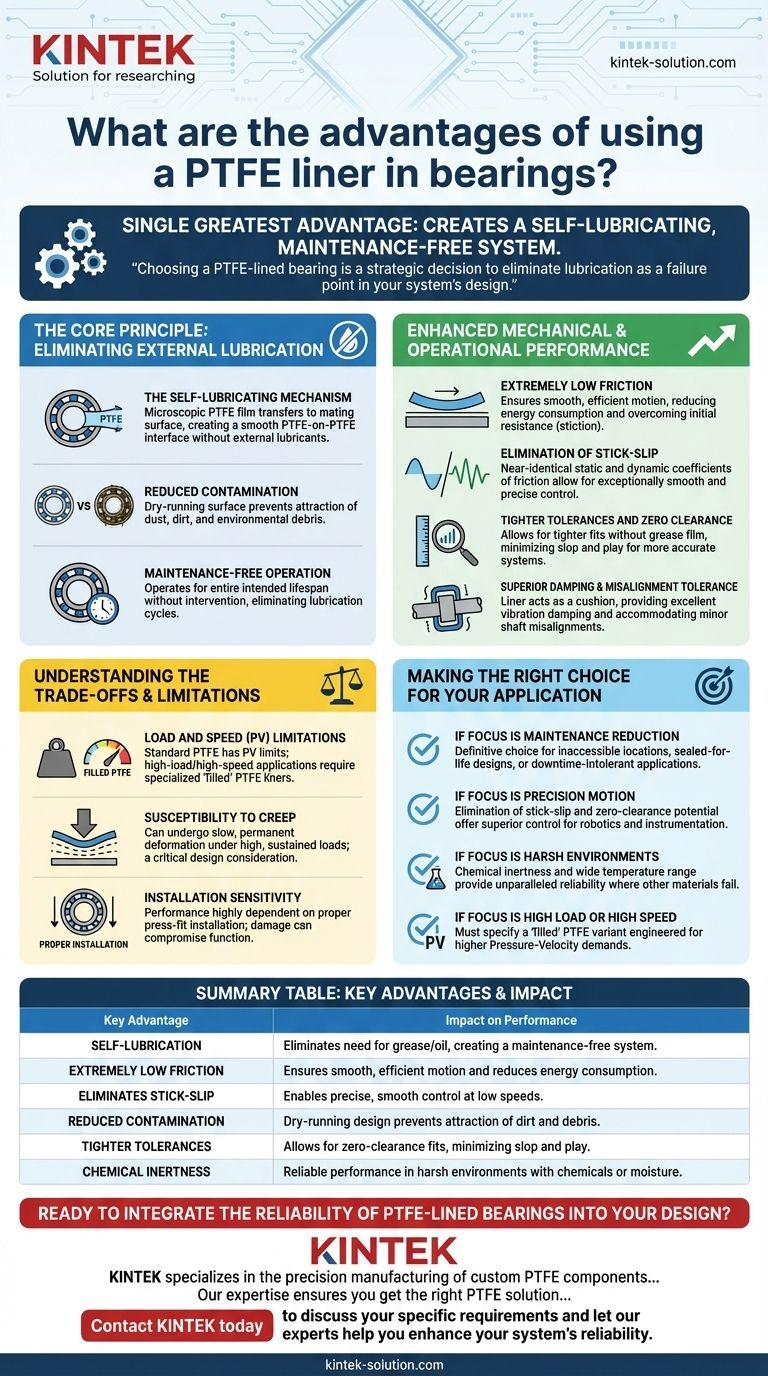

The single greatest advantage of a PTFE liner in a bearing is its ability to create a self-lubricating, maintenance-free system. By incorporating a Polytetrafluoroethylene (PTFE) liner, you eliminate the need for external grease or oil, which in turn reduces friction, prevents the attraction of dirt and contaminants, and dramatically extends the bearing's operational lifespan.

Choosing a PTFE-lined bearing is a strategic decision to eliminate lubrication as a failure point in your system's design. It trades the complexity of ongoing maintenance for the inherent material properties of PTFE, enabling consistent, predictable performance in environments where traditional lubrication is impractical or would certainly fail.

The Core Principle: Eliminating External Lubrication

The most immediate benefit of a PTFE liner is the removal of the entire lifecycle of lubrication management—from application and monitoring to re-application and cleanup. This creates a fundamentally simpler and more reliable mechanical joint.

The Self-Lubricating Mechanism

PTFE possesses one of the lowest coefficients of friction of any solid material. As the bearing operates, a microscopic film of this material transfers to the mating surface, creating a smooth PTFE-on-PTFE interface that requires no external lubricants to function smoothly.

Reduced Contamination

Liquid lubricants like grease and oil are natural magnets for dust, dirt, and other environmental debris. A dry-running PTFE-lined bearing has no such sticky surface, ensuring it remains clean and operates consistently, especially in dirty or exposed conditions.

Maintenance-Free Operation

The combination of self-lubrication and resistance to contamination means these bearings are often described as "maintenance-free." Once installed, they are designed to operate for their entire intended lifespan without intervention.

Enhanced Mechanical and Operational Performance

Beyond just removing the need for grease, the material properties of PTFE directly translate to superior performance characteristics that are difficult to achieve with traditionally lubricated metal bearings.

Extremely Low Friction

The inherently low friction of PTFE ensures smooth, efficient motion. This reduces the energy required to overcome initial resistance (stiction) and maintain movement, leading to more efficient system operation.

Elimination of Stick-Slip

"Stick-slip" is the jerky motion that occurs at very low speeds in other bearings as they cycle between static and dynamic friction. Because PTFE's static and dynamic coefficients of friction are nearly identical, this phenomenon is eliminated, allowing for exceptionally smooth and precise control.

Tighter Tolerances and Zero Clearance

Without the need to accommodate a film of grease, PTFE-lined bearings can be manufactured with much tighter fits. This reduction in internal clearance between the ball and race minimizes slop and play, leading to more accurate and responsive mechanical systems.

Superior Damping and Misalignment Tolerance

The liner acts as a cushion between the metal components, providing excellent vibration damping. It can also accommodate minor shaft misalignments more effectively than a rigid, all-metal bearing, reducing stress on the overall assembly.

Understanding the Trade-offs and Limitations

While powerful, PTFE-lined bearings are not a universal solution. An objective assessment requires understanding their operational boundaries.

Load and Speed (PV) Limitations

Standard PTFE has limits on the Pressure (P) and Velocity (V) it can handle. For high-load or high-speed applications, specialized "filled" PTFE liners are required. These liners include additives like glass fiber, carbon, or graphite to increase their strength and wear resistance, allowing them to handle much higher PV values.

Susceptibility to Creep

Under a high, sustained load, PTFE can be subject to "creep," a slow, permanent deformation. This is a critical design consideration, particularly in applications with high static loads, and is another reason why filled PTFE variants are often specified for demanding roles.

Installation Sensitivity

The performance of a PTFE-lined bearing is highly dependent on a proper press-fit installation. The liner is a relatively thin layer, and damage during installation can compromise the entire bearing's function and lifespan.

Making the Right Choice for Your Application

Selecting the right bearing depends entirely on your primary design goal. PTFE liners offer a distinct set of advantages tailored for specific engineering challenges.

- If your primary focus is maintenance reduction: PTFE is the definitive choice for inaccessible locations, sealed-for-life designs, or applications where downtime is unacceptable.

- If your primary focus is precision motion: The elimination of stick-slip and the potential for zero-clearance fits offer superior control and smoothness for robotics, instrumentation, and control linkages.

- If your primary focus is operation in harsh environments: PTFE's chemical inertness and wide temperature range provide unparalleled reliability where chemicals, moisture, or extreme temperatures would cause other materials to fail.

- If your primary focus is high load or high speed: You must specify a "filled" PTFE variant engineered to handle the higher Pressure-Velocity (PV) demands of your application.

Ultimately, integrating a PTFE liner is an engineering decision to prioritize inherent material reliability over traditional mechanical maintenance.

Summary Table:

| Key Advantage | Impact on Performance |

|---|---|

| Self-Lubrication | Eliminates need for grease/oil, creating a maintenance-free system. |

| Extremely Low Friction | Ensures smooth, efficient motion and reduces energy consumption. |

| Eliminates Stick-Slip | Enables precise, smooth control at low speeds. |

| Reduced Contamination | Dry-running design prevents attraction of dirt and debris. |

| Tighter Tolerances | Allows for zero-clearance fits, minimizing slop and play. |

| Chemical Inertness | Reliable performance in harsh environments with chemicals or moisture. |

Ready to integrate the reliability of PTFE-lined bearings into your design?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right PTFE solution—from prototypes to high-volume orders—to achieve maintenance-free operation, superior precision, and long-lasting performance in your application.

Contact KINTEK today to discuss your specific requirements and let our experts help you enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What temperature range can welded PTFE bellow seals withstand? Unmatched Performance from -200°C to +260°C

- What material are PTFE washers made from? Unlocking the Power of PTFE for Demanding Seals

- What are the standard gasket choices for PTFE rotary lip seals? Ensure Total System Reliability

- What new technologies are being applied to PTFE O-ring seals? Enhance Performance with Nanomaterials & 3D Printing

- What role does longitudinal movement play in PTFE sliding bearing design? A Key to Managing Structural Stress

- What advantages do PTFE spherical balls provide? Unmatched Chemical Resistance & Low Friction

- How is Teflon used in thermal breaks in construction? Enhance Building Energy Efficiency with PTFE

- What are the advantages of PTFE sliding rubber bearings? Achieve Low-Friction, Maintenance-Free Structural Movement