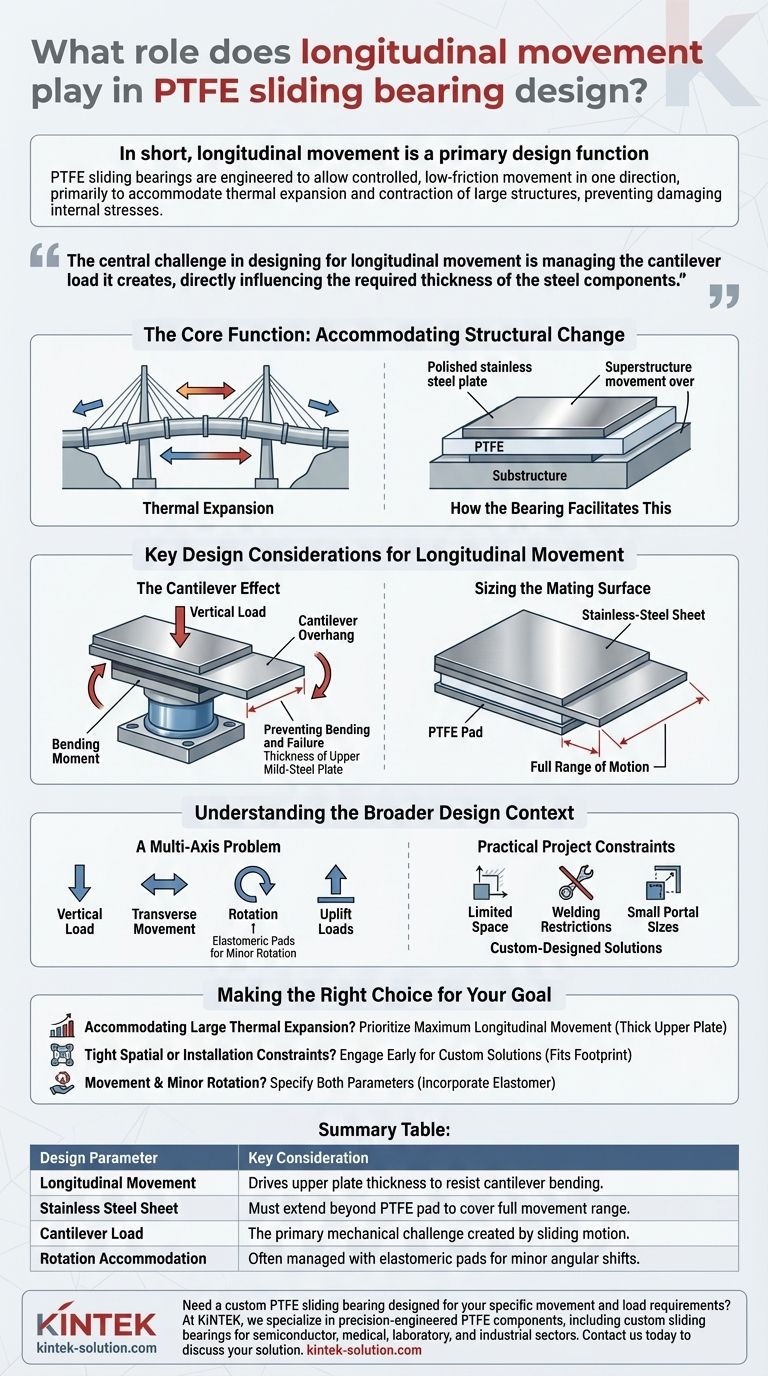

In short, longitudinal movement is a primary design function of PTFE sliding bearings, not a secondary characteristic. These components are engineered specifically to allow controlled, low-friction movement in one direction, primarily to accommodate the thermal expansion and contraction of large structures like pipelines and bridges, preventing the buildup of damaging internal stresses.

The central challenge in designing for longitudinal movement is not the movement itself, but managing the cantilever load it creates. As the upper bearing plate slides, the unsupported overhang must be strong enough to resist bending under load, which directly influences the required thickness of the steel components.

The Core Function: Accommodating Structural Change

PTFE sliding bearings are fundamentally a solution for structures that are not static. They provide a controlled interface where movement can safely occur.

Why Movement is Necessary

Virtually all large-scale structures, particularly those made of steel, are subject to thermal expansion. As ambient temperatures change, the structure expands or contracts.

Without a mechanism to absorb this movement, immense internal stresses would build up, potentially leading to material fatigue, buckling, or catastrophic failure.

How the Bearing Facilitates This

The bearing assembly consists of a polished stainless steel plate sliding over a low-friction PTFE pad.

This simple but effective mechanism allows the superstructure (e.g., a pipeline) to glide smoothly over the substructure, relieving stress as it changes length.

Key Design Considerations for Longitudinal Movement

While the concept is straightforward, its implementation requires careful engineering to ensure the bearing itself does not become a point of failure.

The Cantilever Effect

As the upper bearing element slides longitudinally, the portion extending beyond the lower PTFE pad becomes an unsupported cantilever.

This overhang is still subject to the full vertical load from the structure above.

Preventing Bending and Failure

This cantilever load creates a bending moment that can deform or break the upper plate if it is not sufficiently robust.

Therefore, the thickness of the upper mild-steel plate is a critical design parameter. It must be engineered to resist the maximum anticipated bending moment at the point of greatest movement.

Sizing the Mating Surface

To facilitate the full range of motion, the stainless-steel sheet must extend beyond the PTFE plate. The length of this extension must be equal to or greater than the maximum specified longitudinal movement to ensure a low-friction surface is always present.

Understanding the Broader Design Context

Longitudinal movement is a critical parameter, but it is one of several factors that must be considered in a complete bearing design.

A Multi-Axis Problem

Design specifications from clients typically include more than just one axis of movement. Parameters often include:

- Vertical load: The primary force the bearing must support.

- Transverse movement: Side-to-side motion.

- Rotation: Minor angular shifts, often handled by adding elastomeric pads.

- Uplift loads: Forces that could try to separate the bearing plates.

Accommodating Minor Rotation

While designed for translation, some minor rotation or misalignment is often unavoidable.

Small amounts of rotation (fractions of a degree) can be compensated for by incorporating an elastomer like neoprene into the assembly. Thicker elastomers can handle more rotation but may introduce stability issues.

Practical Project Constraints

Engineers often face real-world challenges where bearings are specified late in the design process.

Limited space between the substructure and superstructure, restrictions on welding, or small portal plate sizes all necessitate custom-designed solutions rather than off-the-shelf products.

Making the Right Choice for Your Goal

When specifying a PTFE sliding bearing, your primary objective will dictate the most critical design considerations.

- If your primary focus is accommodating large thermal expansion: Prioritize specifying the maximum required longitudinal movement to ensure the upper steel plate is thick enough to handle the resulting cantilever load.

- If your project has tight spatial or installation constraints: Engage with the bearing manufacturer early in the process to develop a custom solution that fits within the available footprint.

- If your structure will experience both movement and minor rotation: Clearly specify both parameters, as the design will need to incorporate an elastomeric element to safely manage the angular shift.

By understanding the direct relationship between longitudinal movement and the structural demands it places on the bearing components, you can confidently specify a solution that ensures long-term integrity.

Summary Table:

| Design Parameter | Key Consideration |

|---|---|

| Longitudinal Movement | Drives upper plate thickness to resist cantilever bending. |

| Stainless Steel Sheet | Must extend beyond PTFE pad to cover full movement range. |

| Cantilever Load | The primary mechanical challenge created by sliding motion. |

| Rotation Accommodation | Often managed with elastomeric pads for minor angular shifts. |

Need a custom PTFE sliding bearing designed for your specific movement and load requirements?

At KINTEK, we specialize in precision-engineered PTFE components, including custom sliding bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your bearing can handle the exact longitudinal movement, cantilever loads, and spatial constraints of your project—from prototype to high-volume production.

Contact us today to discuss how we can deliver a reliable, high-performance solution for your structural needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials