In short, the primary advantages of PTFE sliding rubber bearings are their unique combination of exceptionally low friction, high load-bearing capacity, and maintenance-free operation. They allow heavy structures like bridges to expand, contract, and shift smoothly without generating harmful stress, all while providing a durable and cost-effective solution.

The core value of a PTFE sliding bearing lies in its ability to decouple vertical load support from horizontal movement. The rubber element absorbs the vertical load, while the specialized PTFE and stainless steel surfaces provide a near-frictionless plane for translation, protecting the structure's integrity.

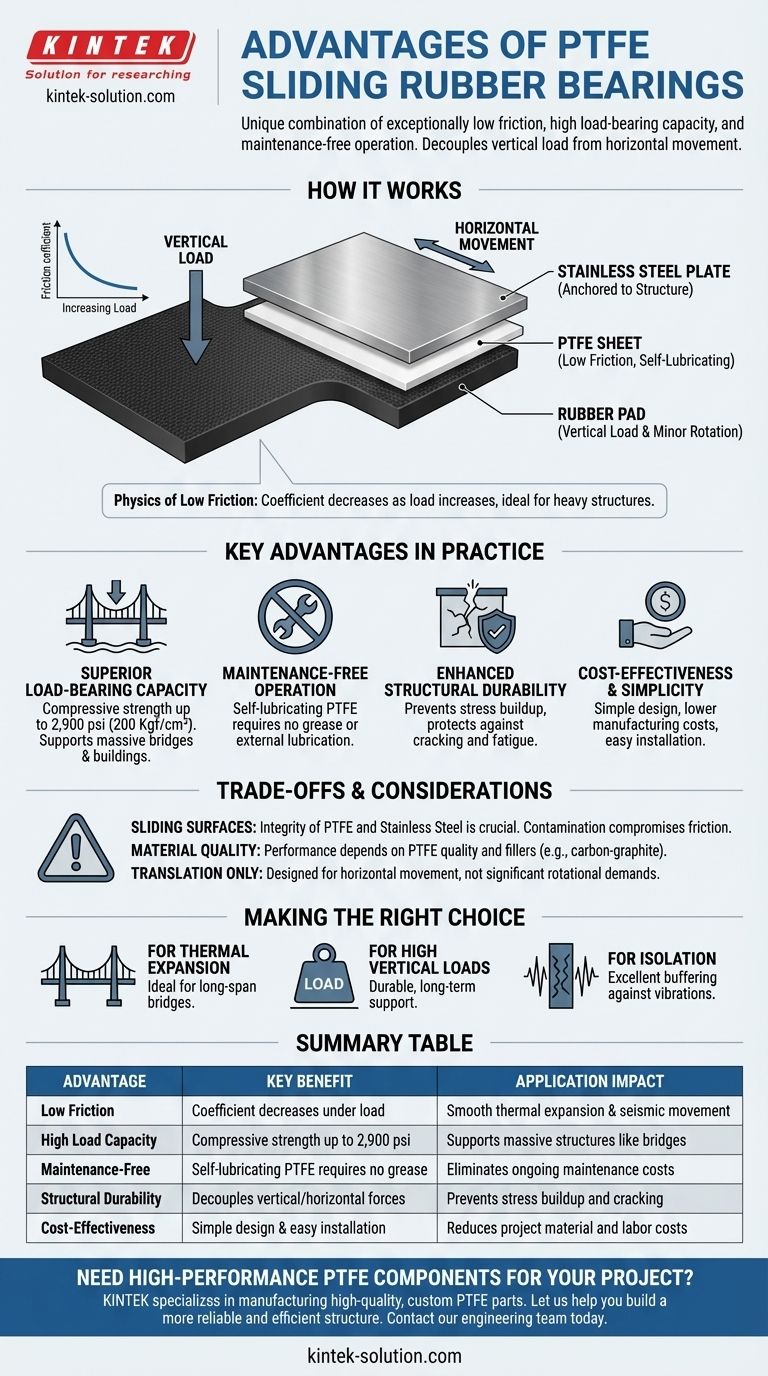

How PTFE Bearings Fundamentally Work

To understand their advantages, it's essential to understand their design. These are not simple blocks of material; they are engineered components designed for a specific purpose.

The Core Components

A typical PTFE sliding bearing is a laminated assembly. It consists of a standard elastomeric (rubber) bearing pad that accommodates vertical loads and minor rotations.

On top of this rubber pad, a PTFE (polytetrafluoroethylene) sheet is bonded. This PTFE layer slides against a polished stainless steel plate that is anchored to the structure's upper element.

The Physics of Low Friction

PTFE is renowned for having the lowest coefficient of friction of any known solid material. This property is the key to the bearing's performance.

Crucially, this coefficient of friction actually decreases as the load increases. This makes it exceptionally effective for heavy civil engineering applications where massive forces are at play.

Decoupling Vertical and Horizontal Forces

This design effectively separates two distinct jobs. The robust rubber bearing supports the immense vertical weight of the structure.

Simultaneously, the PTFE-on-steel sliding surface allows for significant horizontal translation with minimal resistance. This accommodates movements caused by thermal expansion, wind, or seismic activity.

Key Advantages in Practice

This intelligent design translates directly into tangible benefits for large-scale construction and industrial projects.

Superior Load-Bearing Capacity

PTFE has an excellent compressive strength, capable of absorbing pressures up to 2,900 psi (200 Kgf/cm²). This is approximately double the capacity of standard neoprene pads.

This allows for the support of massive loads in bridges, buildings, and heavy factory equipment, ensuring stability and safety.

Maintenance-Free Operation

The inherent properties of PTFE make it a self-lubricating material. Unlike mechanical bearings, it requires no grease or external lubrication throughout its service life.

This eliminates ongoing maintenance costs and inspection requirements, making it a "fit and forget" solution.

Enhanced Structural Durability

By allowing for smooth, controlled movement, these bearings prevent the buildup of stress within the primary structure.

They effectively absorb and isolate the superstructure from movements in the substructure, protecting concrete and steel from cracking and fatigue over decades.

Cost-Effectiveness and Simplicity

Compared to more complex mechanical bearing systems, PTFE sliding bearings have a simple structure that is less expensive to manufacture.

They are also easy to install and replace. Their low profile can even contribute to a lower overall building or bridge height, reducing material costs for the entire project.

Understanding the Trade-offs and Considerations

While highly effective, PTFE bearings are not a universal solution. Their performance is contingent on specific conditions and quality control.

Importance of the Sliding Surfaces

The system's low friction is dependent on the integrity of both the PTFE and the polished stainless steel plate.

Contamination by dust, debris, or corrosion on the steel plate can significantly increase the coefficient of friction and compromise the bearing's effectiveness.

Material Quality is Paramount

The performance specifications of the PTFE itself are critical. Fillers, such as carbon-graphite, are often added to enhance mechanical properties and wear resistance.

The manufacturing and testing process must be rigorous to ensure the PTFE plate can withstand the specified loads and repeated movements without degradation. This is why they undergo specific friction and wear resistance tests.

Designed for Translation, Not High Rotation

These bearings excel at allowing horizontal movement (translation). While the underlying rubber pad can accommodate some minor rotation, they are not designed for significant rotational demands.

For structures requiring high rotation, such as complex interchanges or curved bridges, a different type of bearing (like a spherical or pot bearing) may be more appropriate.

Making the Right Choice for Your Structure

Selecting the correct bearing is a critical engineering decision. Your choice should be guided by the primary demands of the structure.

- If your primary focus is accommodating thermal expansion in long-span bridges: The near-frictionless horizontal translation offered by PTFE bearings is the ideal and most efficient solution.

- If your primary focus is supporting high vertical loads with minimal maintenance: The combination of high compressive strength and self-lubricating PTFE provides a durable, long-term, and cost-effective system.

- If your primary focus is isolating a structure from low-frequency vibrations or movements: The buffering and isolation properties of the integrated rubber and sliding elements make this an excellent choice.

By understanding the principles behind their design, you can confidently specify PTFE sliding bearings for applications where they provide unparalleled performance and value.

Summary Table:

| Advantage | Key Benefit | Application Impact |

|---|---|---|

| Low Friction | Coefficient of friction decreases under load | Smooth thermal expansion & seismic movement |

| High Load Capacity | Compressive strength up to 2,900 psi | Supports massive structures like bridges |

| Maintenance-Free | Self-lubricating PTFE requires no grease | Eliminates ongoing maintenance costs |

| Structural Durability | Decouples vertical/horizontal forces | Prevents stress buildup and cracking |

| Cost-Effectiveness | Simple design & easy installation | Reduces project material and labor costs |

Need High-Performance PTFE Components for Your Project?

PTFE sliding bearings are a perfect example of how precision-engineered PTFE components solve complex engineering challenges. At KINTEK, we specialize in manufacturing high-quality, custom PTFE parts—from seals and liners to specialized labware and bearing components.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production. Our focus on precision ensures your components meet the highest standards for performance and durability.

Let us help you build a more reliable and efficient structure. Contact our engineering team today to discuss your specific PTFE component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs