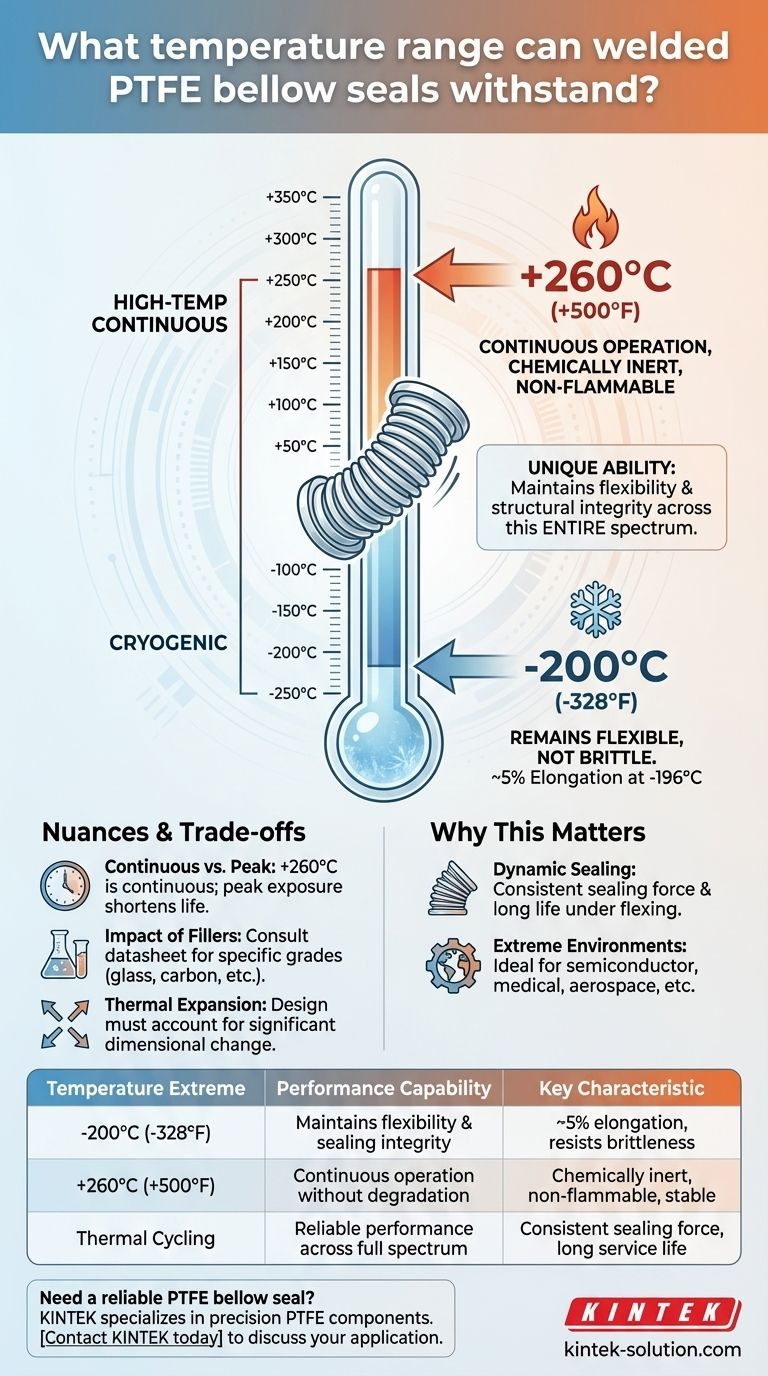

In short, welded PTFE bellow seals can operate reliably within an exceptionally wide temperature range, from cryogenic lows of approximately -200°C (-328°F) to continuous high temperatures of +260°C (+500°F). This remarkable thermal stability allows them to maintain their structural integrity and sealing performance in environments where most other materials would fail.

The true value of PTFE is not just its wide temperature tolerance, but its ability to retain critical mechanical properties—like flexibility—across that entire spectrum. This makes it uniquely suited for dynamic sealing applications like bellows in the most demanding thermal conditions.

The Exceptional Thermal Range of PTFE Explained

To properly apply a PTFE bellow seal, it's crucial to understand how the material behaves at the extremes of its operational window. Its performance is not merely about survival; it's about consistent, reliable function.

Performance in Cryogenic Conditions

At the low end of the spectrum, PTFE excels. It can withstand temperatures down to -200°C (-328°F) without becoming brittle.

Crucially for a bellow seal, which must flex, PTFE maintains significant elongation (around 5%) even at -196°C. This means it remains pliable enough to function as a dynamic seal in cryogenic applications.

Stability at High Temperatures

On the high end, PTFE offers a continuous service temperature of +260°C (+500°F). Some grades can handle brief excursions to even higher temperatures, approaching 300°C (572°F).

This performance is complemented by PTFE's inherent chemical inertness and non-flammability. These properties make it an ideal choice for high-temperature environments involving steam, petroleum processing, or even aerospace applications.

Why This Matters for Bellow Seals

A bellow seal is not a static component; it is designed to compress, extend, and flex.

PTFE's ability to perform this role without cracking in extreme cold or degrading in high heat is its core advantage. This thermal stability ensures a consistent sealing force and long service life across wide temperature cycles.

Understanding the Nuances and Trade-offs

While the general temperature range is a reliable guide, a technical advisor must point out the critical details that ensure successful implementation. Misunderstanding these can lead to premature failure.

"Continuous" vs. "Peak" Temperature

The commonly cited limit of +260°C (+500°F) is for continuous operation. The material can perform indefinitely at this temperature without significant degradation.

Some sources may cite higher peak temperatures, but exposing the seal to these temperatures for extended periods will shorten its operational lifespan and can compromise its mechanical properties.

The Impact of Fillers and Grades

The figures provided are for pure, virgin PTFE. Many applications use filled grades of PTFE (e.g., filled with glass, carbon, or bronze) to enhance properties like compressive strength or wear resistance.

These fillers can slightly alter the thermal limits of the material. It is essential to consult the specific datasheet for the exact grade of PTFE being used in your bellow seal.

Thermal Expansion is a Design Factor

Like all materials, PTFE expands and contracts with temperature changes. Given its exceptionally wide operating range, the total change in dimension can be significant.

Engineers must account for PTFE's coefficient of thermal expansion during the design phase to ensure the seal maintains proper contact and pressure throughout the entire temperature cycle.

Making the Right Choice for Your Environment

Your specific application will determine which aspect of PTFE's thermal performance is most critical.

- If your primary focus is cryogenic sealing: PTFE is a premier choice due to its unique ability to remain flexible and functional at temperatures approaching -200°C.

- If your primary focus is high-temperature stability: PTFE provides a high continuous service temperature of 260°C, combined with chemical inertness that is vital for aggressive media.

- If your primary focus is wide thermal cycling: PTFE is one of the few materials that can reliably handle repeated cycles from deep cold to high heat without compromising its sealing integrity.

Ultimately, PTFE's unparalleled thermal range makes it a definitive material for welded bellow seals in the most extreme industrial and scientific applications.

Summary Table:

| Temperature Extreme | Performance Capability | Key Characteristic |

|---|---|---|

| Cryogenic: -200°C (-328°F) | Maintains flexibility and sealing integrity | ~5% elongation even at -196°C, resists brittleness |

| High-Temp: +260°C (+500°F) | Continuous operation without degradation | Chemically inert, non-flammable, stable performance |

| Thermal Cycling | Reliable performance across full temperature spectrum | Maintains consistent sealing force and long service life |

Need a PTFE bellow seal that performs reliably in extreme temperatures?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the most demanding applications in semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures your bellow seals are optimized for your specific thermal and chemical environment, from prototypes to high-volume orders.

Contact KINTEK today to discuss your application requirements and benefit from our material science expertise.

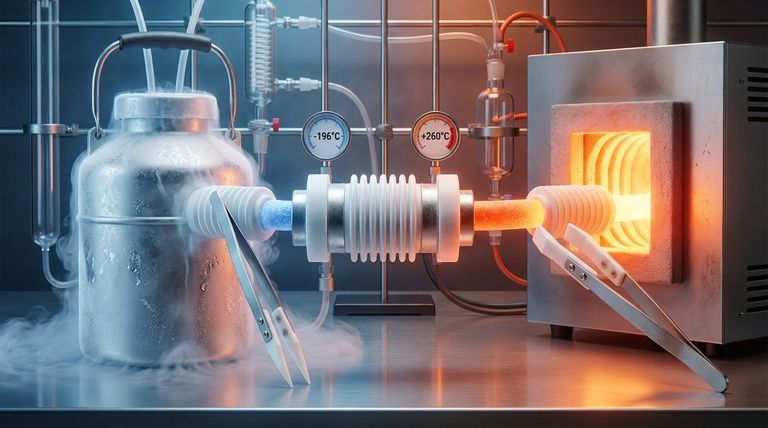

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some examples of electrical insulation products that can be made from PTFE? High-Performance Solutions for Demanding Applications

- How should the right PTFE washer thickness be selected? Balance Sealing, Creep, and Pressure

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- Why are PTFE gaskets considered a preferred sealing solution? Ensure Reliability in Demanding Environments

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions

- What temperature range can ePTFE gaskets operate within? Seal from -200°C to 315°C

- What are the process advantages of machining Teflon? High-Speed Production with Superior Thermal Stability

- What are the applications of barium sulphate fillers in PTFE? Enhance Chemical Purity & Dimensional Stability