The primary advantages of PTFE gaskets are their near-universal chemical resistance, exceptional performance across a wide temperature range, and long-term sealing reliability. Made from Polytetrafluoroethylene, these gaskets provide a durable seal in harsh industrial environments where other materials would quickly fail, resisting everything from aggressive acids to cryogenic temperatures without aging or degrading.

The core reason to choose a PTFE gasket is for its chemical inertness and thermal stability in demanding applications. However, a successful implementation requires understanding its mechanical limitations, specifically its tendency to "creep" under pressure.

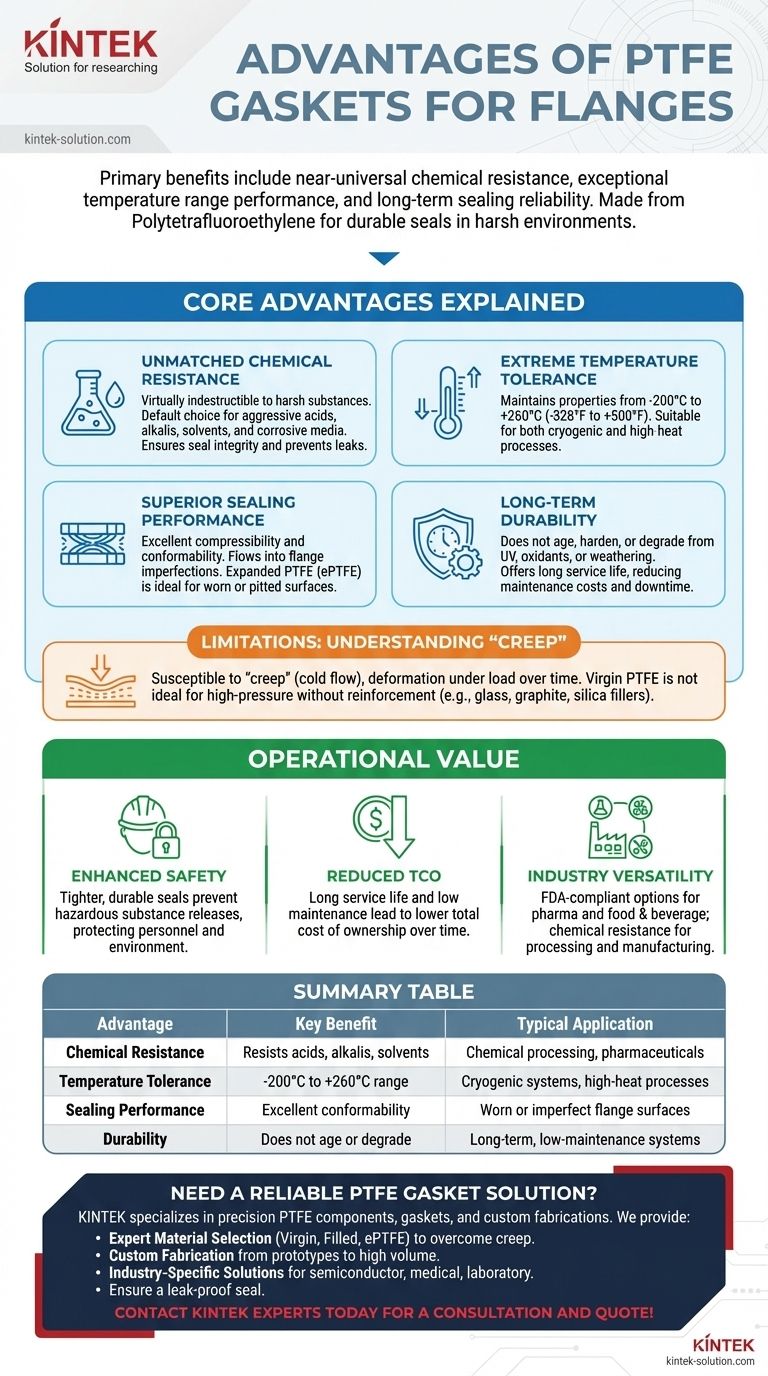

The Core Advantages of PTFE Gaskets Explained

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually indestructible to most harsh substances.

This makes PTFE gaskets the default choice for applications involving aggressive acids, alkalis, solvents, and other corrosive media. They ensure the integrity of the seal and prevent dangerous leaks.

Extreme Temperature Tolerance

PTFE gaskets operate effectively in conditions where most other sealing materials would become brittle or degrade.

They maintain their physical properties and sealing capability across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This makes them suitable for both cryogenic and high-heat processes.

Superior Sealing Performance

PTFE provides excellent compressibility and conformability. This allows the gasket to flow into minor imperfections on flange faces, creating a tight, leak-proof seal.

For worn, pitted, or damaged flanges, expanded PTFE (ePTFE) is particularly effective. Its soft, form-in-place nature ensures a reliable seal even on less-than-perfect surfaces.

Long-Term Durability and Low Maintenance

Unlike many elastomers, PTFE does not age, harden, or degrade when exposed to UV radiation, oxidants, or general weathering.

This inherent stability translates to a very long service life. The durability of PTFE gaskets reduces the need for frequent replacement, which in turn lowers maintenance costs and minimizes operational downtime.

Understanding the Trade-offs: The Limitations of PTFE

No material is perfect, and being an objective advisor means acknowledging a material's weaknesses. The primary limitation of pure PTFE is its mechanical behavior under load.

The Challenge of "Creep" (Cold Flow)

The most significant drawback of PTFE is its tendency to creep, also known as cold flow. This is the material's inclination to slowly deform or "flow" away from a concentrated load over time.

In a bolted flange joint, this means the gasket can thin out under the sustained pressure of the bolts, leading to a loss of bolt torque and a potential leak path.

Not Ideal for High-Pressure Applications (Without Reinforcement)

Because of its susceptibility to creep, virgin (pure) PTFE is generally not recommended for high-pressure or critical service applications without some form of reinforcement.

To counteract creep, manufacturers often add fillers like glass, graphite, or silica to the PTFE. These "filled PTFE" gaskets offer improved mechanical strength and creep resistance while retaining most of the material's chemical and thermal benefits.

How These Advantages Translate to Operational Value

The technical properties of PTFE gaskets provide tangible benefits that impact safety, cost, and efficiency.

Enhanced Safety and Reliability

By providing a tight, durable seal against aggressive chemicals, PTFE gaskets are critical for enhancing process safety. They prevent the release of hazardous substances, protecting personnel and the environment.

Reduced Total Cost of Ownership

While the initial cost of a PTFE gasket may be higher than some alternatives, its long service life and low maintenance requirements result in a lower total cost of ownership. Fewer replacements and less downtime lead to significant long-term savings.

Versatility Across Industries

The unique combination of properties makes PTFE suitable for a vast range of industries. Its non-toxic, FDA-compliant options are ideal for pharmaceutical and food & beverage applications, while its chemical resistance is essential for chemical processing and manufacturing.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE gasket is the correct solution for your specific needs.

- If your primary focus is handling aggressive chemicals or high-purity media: PTFE is almost certainly your best choice due to its unmatched chemical inertness.

- If you are sealing in extreme temperature environments (hot or cryogenic): PTFE's exceptionally wide operating range makes it a top contender.

- If your application involves very high mechanical pressure and bolt loads: You must consider a filled or reinforced PTFE gasket to mitigate the effects of creep and ensure a stable seal.

- If you are dealing with older or slightly damaged flange surfaces: Look specifically for expanded PTFE (ePTFE) gaskets, which offer superior conformability.

Ultimately, selecting the right gasket requires matching the material's distinct strengths and weaknesses to the specific demands of your application.

Summary Table:

| Advantage | Key Benefit | Typical Application |

|---|---|---|

| Chemical Resistance | Resists acids, alkalis, solvents | Chemical processing, pharmaceuticals |

| Temperature Tolerance | -200°C to +260°C range | Cryogenic systems, high-heat processes |

| Sealing Performance | Excellent conformability | Worn or imperfect flange surfaces |

| Durability | Does not age or degrade | Long-term, low-maintenance systems |

Need a Reliable PTFE Gasket Solution?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including gaskets, seals, and custom fabrications. Our expertise ensures you get a sealing solution that perfectly matches your application's demands for chemical resistance, temperature stability, and long-term reliability.

We provide:

- Expert Material Selection: Guidance on choosing between virgin, filled, or expanded PTFE (ePTFE) to overcome limitations like creep.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your specific flange requirements.

- Industry-Specific Solutions: Proven components for semiconductor, medical, laboratory, and industrial applications.

Ensure a leak-proof, durable seal for your critical processes. Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE enhance baseball equipment? Unlock Faster Swings and Longer-Lasting Gear

- What are the physical and chemical properties of pure PTFE bushings? Unlock Extreme Chemical & Thermal Resistance

- What are the main benefits of using a Teflon sheet for heat press? Achieve Flawless, Professional Transfers

- What are the main differences between solid Teflon O-rings and Teflon encapsulated O-rings? Choose the Right Seal for Harsh Environments

- Why are custom Teflon rotary shaft seals preferred for demanding applications? Achieve Superior Reliability in Extreme Conditions

- What are the benefits of PTFE bushes over plastic bushings? Superior Performance for Harsh Environments

- What are the advantages of using PTFE for spring-energized seal jackets? Superior Performance in Extreme Conditions

- What temperature range can PTFE impellers withstand? Operate from -200°C to 260°C