At a glance, the fundamental difference lies in their construction and flexibility. A solid Teflon O-ring is made entirely from rigid PTFE, offering supreme chemical and thermal resistance but almost no elasticity. In contrast, a Teflon encapsulated O-ring features a flexible elastomer core (like Silicone or FKM) wrapped in a thin, seamless Teflon jacket, combining the chemical inertness of Teflon with the flexibility required for a reliable seal.

The core decision is a trade-off between absolute purity and mechanical performance. Solid Teflon is for extreme, static environments where chemical inertness is the only priority, while encapsulated Teflon provides the elasticity needed for effective sealing in a much wider range of applications.

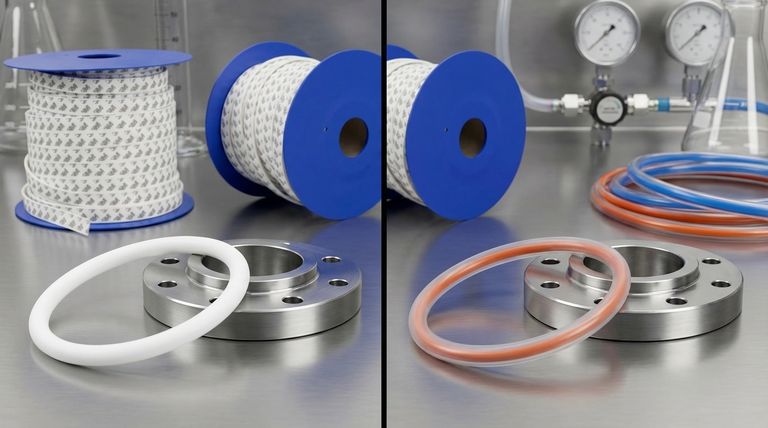

Deconstructing the Two O-Ring Designs

To understand which O-ring is right for your application, you must first appreciate their fundamental structural differences. One is a monolithic material, while the other is a hybrid composite, each designed to solve a different engineering problem.

Solid Teflon (PTFE) O-Rings: The Pure Performer

A solid O-ring is machined from a single piece of Polytetrafluoroethylene (PTFE).

This monolithic design gives it an exceptional operational temperature range, from -250°C to +260°C, and makes it virtually immune to aggressive chemicals.

However, its greatest strength is also its critical weakness: PTFE is a rigid material with very poor "memory." It does not compress and rebound like rubber, making it difficult to achieve and maintain a consistent seal.

Teflon Encapsulated O-Rings: The Hybrid Solution

An encapsulated O-ring is a two-part system designed to offer the best of both worlds.

It starts with an inner core made from an elastomer, such as Silicone or FKM (Viton). This core provides the flexibility, resilience, and "bounce" of a traditional rubber O-ring.

This core is then seamlessly enclosed within an outer jacket of Teflon resin, typically FEP or PFA. This jacket provides the chemical resistance and low-friction surface, protecting the vulnerable core from the process media.

Key Performance Factors Compared

The structural differences directly translate into distinct performance characteristics. Your application's mechanical and chemical demands will determine which factors are most critical.

Elasticity and Sealing Force

Solid Teflon O-rings have very low elasticity. They rely on being perfectly compressed into a groove to create a seal and are highly susceptible to leaking if pressure or temperature fluctuations occur.

Encapsulated O-rings behave much more like standard rubber O-rings. The elastomer core provides a constant, live sealing force, allowing it to adapt to minor imperfections and maintain integrity during pressure cycles.

Chemical and Thermal Resistance

Solid Teflon O-rings offer the absolute gold standard in resistance. Because the entire body is pure PTFE, there are no concerns about a weaker material being exposed.

Encapsulated O-rings offer nearly the same level of chemical resistance due to the outer jacket. However, their overall temperature rating is often limited by the inner core material, which may have a lower maximum temperature than the FEP or PFA jacket.

Application Suitability

Solid Teflon O-rings are best suited for completely static face seals where extreme chemical purity or temperature is the overriding concern and the hardware is precisely machined.

Encapsulated O-rings are far more versatile. Their flexibility makes them ideal for a wide range of static and semi-dynamic applications, such as in pump housings, filters, and flanges where a reliable, leak-free seal is non-negotiable.

Understanding the Trade-offs and Limitations

Choosing the wrong O-ring can lead to costly downtime and system failure. Understanding the inherent compromises of each design is critical for making a reliable decision.

The Rigidity Problem of Solid Teflon

The primary drawback of solid PTFE is its tendency to creep or cold-flow under pressure. This means it can permanently deform over time, causing the seal to loosen and eventually fail. Installation can also be difficult without overstretching and damaging the ring.

The Durability Concern of Encapsulated Jackets

The main vulnerability of an encapsulated O-ring is its thin Teflon jacket. This jacket is susceptible to scratching, nicking, or abrasive wear. Any breach in the jacket exposes the chemically weaker inner core, which can be quickly degraded by the process media, leading to rapid seal failure.

The Cost Factor

Due to their complex, multi-material manufacturing process, encapsulated O-rings are significantly more expensive than their solid Teflon counterparts. This cost must be weighed against the greater reliability and versatility they provide.

Making the Right Choice for Your Application

Your selection depends entirely on balancing the need for chemical purity against the mechanical demands of the seal.

- If your primary focus is maximum chemical inertness in a purely static seal: A solid Teflon (PTFE) O-ring is the most robust choice, provided your hardware is precise and the conditions are stable.

- If your primary focus is a reliable, resilient seal against harsh chemicals: A Teflon encapsulated O-ring provides the essential flexibility that a solid ring lacks, making it the safer and more versatile option for most static and semi-dynamic needs.

- If your application involves potential abrasion or sharp hardware edges: The vulnerability of the encapsulated jacket is a major risk, and you must proceed with caution, ensuring surfaces are smooth and installation is careful.

Understanding this fundamental trade-off between rigid purity and flexible performance is the key to specifying the correct O-ring and ensuring long-term system integrity.

Summary Table:

| Feature | Solid Teflon O-Ring | Teflon Encapsulated O-Ring |

|---|---|---|

| Construction | Monolithic PTFE | Elastomer core with Teflon jacket |

| Flexibility | Very Low (Rigid) | High (Flexible) |

| Chemical Resistance | Supreme | Excellent (dependent on jacket integrity) |

| Temperature Range | -250°C to +260°C | Limited by core material (e.g., Silicone, FKM) |

| Primary Application | Static seals, extreme purity/heat | Static & semi-dynamic seals, reliable sealing |

| Key Limitation | Creep/Cold-Flow, difficult installation | Jacket vulnerability to abrasion, higher cost |

Need a High-Performance PTFE Seal for Your Critical Application?

Choosing between a solid or encapsulated Teflon O-ring is critical for the integrity of your system. At KINTEK, we specialize in manufacturing precision PTFE components, including custom O-rings, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors.

We understand the trade-offs between chemical purity and mechanical performance. Our experts can help you select or custom-fabricate the perfect seal—from prototypes to high-volume orders—ensuring it meets your exact requirements for chemical resistance, temperature, and pressure.

Let us provide a sealing solution that guarantees reliability and longevity.

Contact our engineering team today for a consultation to discuss your specific needs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance