At its core, pure Polytetrafluoroethylene (PTFE) is defined by two dominant characteristics. Physically, it possesses one of the lowest coefficients of friction of any solid material, making it exceptionally slippery. Chemically, it is almost completely inert, resisting attack from nearly all chemicals and solvents across a vast temperature range.

The true value of a pure PTFE bushing lies in its unique combination of extreme chemical inertness and self-lubricating, non-stick surfaces. This makes it a specialized material for applications where resistance to harsh environments is more critical than high mechanical strength.

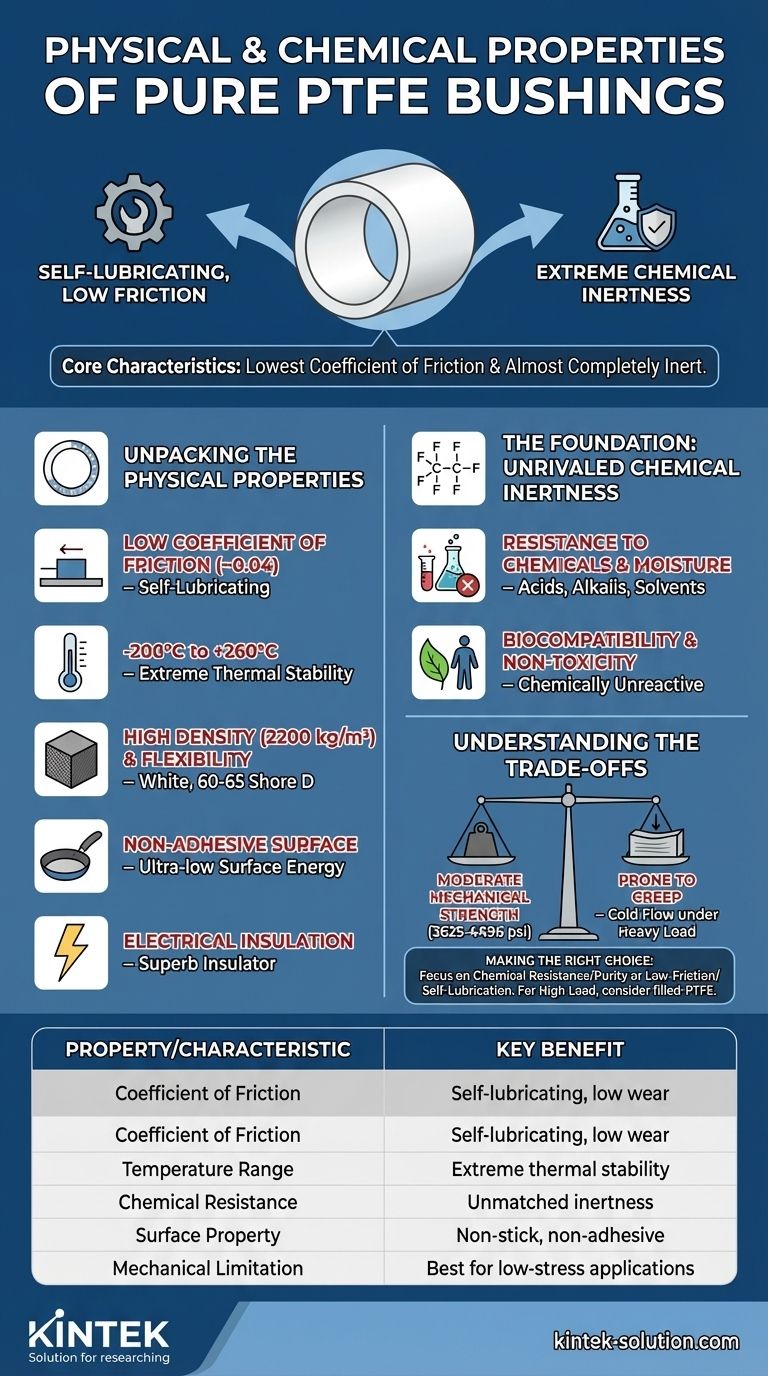

Unpacking the Physical Properties

The physical behaviors of PTFE directly enable its most common applications, from non-stick coatings to high-performance bearings.

The Signature Low Coefficient of Friction

PTFE has an exceptionally low friction coefficient, approximately 0.04. This allows it to function as a self-lubricating material.

This property is critical for components in motion, as it minimizes wear, reduces energy consumption, and ensures quiet operation with little to no maintenance.

Exceptional Thermal Stability

Pure PTFE bushings can withstand huge temperature swings, operating reliably from cryogenic lows of -200°C up to +260°C (-328°F to +500°F).

It has a very high melting point of approximately 327°C (621°F), ensuring its structural integrity in high-heat applications.

High Density and Material Characteristics

PTFE is a dense polymer, with a typical density of 2200 kg/m³. It is also highly flexible, allowing it to conform well to mating surfaces.

Visually, it is white. Its hardness is rated at 60-65 Shore D, which is firm but softer than many engineering plastics.

Non-Adhesive Surface

The material has an ultra-low surface energy, which gives it powerful non-adhesive or "non-stick" properties.

This prevents other materials from sticking to the bushing, which is invaluable in food processing and medical applications where contamination must be avoided and cleaning must be easy.

Electrical Insulation

PTFE is a superb electrical insulator, making it a valuable material for electronic components where conductivity must be prevented.

The Foundation: Unrivaled Chemical Inertness

The chemical properties of PTFE are a direct result of its molecular structure—a high-molecular-weight compound consisting solely of strong carbon-fluorine bonds.

Resistance to Chemicals and Moisture

PTFE offers outstanding resistance to nearly all acids, alkalis, and solvents.

It is also highly resistant to moisture, preventing absorption or degradation in wet or humid environments. This contributes to its excellent environmental tolerance.

Biocompatibility and Non-Toxicity

Because PTFE is chemically unreactive and insoluble, it is considered non-toxic and biocompatible.

This chemical stability is why it is trusted for sensitive applications in the medical, pharmaceutical, and food production industries, including use in catheter coatings.

Understanding the Trade-offs

While its properties are exceptional, pure PTFE is not universally ideal. Its primary limitations are mechanical.

Moderate Mechanical Strength

Pure PTFE is a relatively soft material. Its tensile strength, while respectable at 3625-4496 psi, is lower than many other engineering polymers.

Prone to Creep

Under a constant, heavy load, pure PTFE can be susceptible to "creep" or cold flow, meaning it can slowly deform over time. This must be a key consideration in high-load structural designs.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is chemical resistance and purity: Pure PTFE is an ideal choice for components in chemical processing, medical devices, or food-grade machinery where inertness is non-negotiable.

- If your primary focus is low-friction, self-lubricating motion: PTFE excels in bearings, seals, and sliding components, especially where external lubricants are undesirable or impractical.

- If your primary focus is high load capacity or abrasion resistance: You should consider filled-PTFE grades (e.g., glass or carbon-filled) or alternative polymers, as pure PTFE may deform or wear too quickly under high mechanical stress.

Ultimately, leveraging PTFE effectively means embracing its strengths in extreme environments while respecting its mechanical limitations.

Summary Table:

| Property | Value / Characteristic | Key Benefit |

|---|---|---|

| Coefficient of Friction | ~0.04 | Self-lubricating, low wear |

| Temperature Range | -200°C to +260°C | Extreme thermal stability |

| Chemical Resistance | Resists nearly all acids, alkalis, solvents | Unmatched inertness |

| Surface Property | Ultra-low surface energy | Non-stick, non-adhesive |

| Mechanical Limitation | Moderate strength, prone to creep under load | Best for low-stress applications |

Leverage the unique properties of PTFE for your most demanding applications.

At KINTEK, we specialize in manufacturing high-precision, pure PTFE components—including bushings, seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a component that delivers superior chemical resistance, self-lubrication, and thermal stability.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific requirements.

Contact our experts today to discuss how our PTFE solutions can solve your engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications