At its core, a Teflon sheet serves three primary functions in a heat press workflow: it protects your garment from scorching, it shields your heat platen from residue, and it helps ensure heat is distributed evenly for a flawless transfer. This simple accessory acts as a critical barrier between the intense heat of the press and your materials.

While often seen as optional, a Teflon sheet is the most effective and inexpensive insurance policy against the most common heat press failures. It elevates your work from amateur to professional by managing heat, preventing stains, and protecting both your project and your equipment.

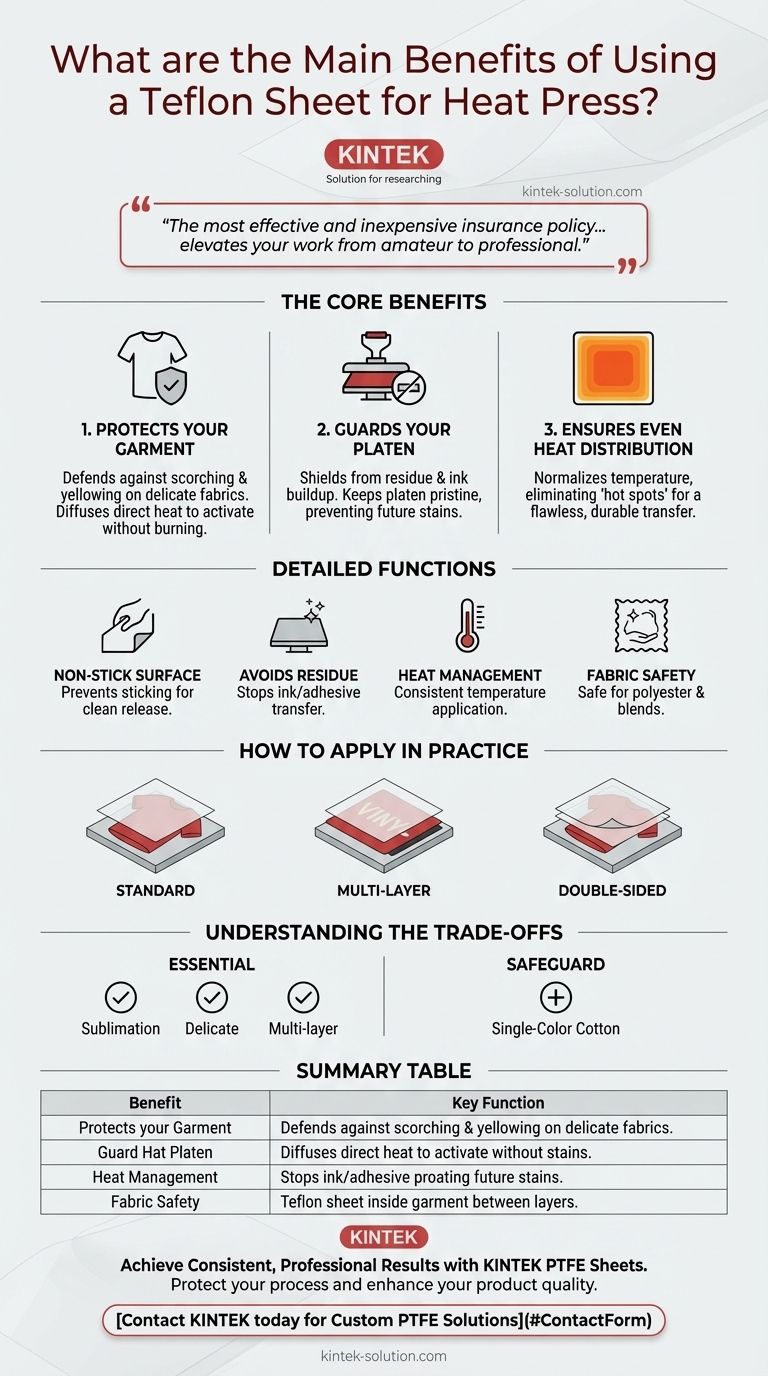

The Core Functions of a Teflon Sheet

A Teflon sheet is more than just a protective layer; it's an active component in achieving a high-quality finish. Its unique properties directly address the main variables that can ruin a heat transfer project.

It Protects Your Garment from Damage

The most immediate benefit is safeguarding the fabric. The sheet acts as a buffer, diffusing direct heat to prevent the tell-tale scorching or yellowing that can occur on delicate materials like polyester or blends.

By creating a barrier, it ensures the heat activates the adhesive or ink without burning the surrounding fibers.

It Guards Your Heat Press Platen

Residue is the enemy of a clean heat press. Without a protective sheet, excess ink from sublimation prints or stray adhesive from heat transfer vinyl (HTV) can permanently bond to the upper platen.

This buildup can then transfer onto subsequent projects, causing stains and forcing costly, time-consuming cleaning. A Teflon sheet keeps your platen pristine.

It Ensures Even Heat Distribution

Heating elements within a platen can sometimes have minor "hot spots." A Teflon sheet helps to normalize these temperature variations across the entire surface of your design.

This even distribution is critical for ensuring that all parts of the transfer receive the correct temperature for the correct duration, resulting in a consistent and durable application.

It Provides a Critical Non-Stick Surface

The non-stick nature of Teflon prevents the transfer paper or vinyl carrier from sticking to the hot platen. This ensures a clean release after pressing, preventing smudges or accidental peeling of the design.

How to Apply It in Practice

Using a Teflon sheet is straightforward, but its placement depends on the project. Correct usage maximizes its protective benefits.

For Standard Single-Sided Transfers

This is the most common use. Simply place your garment and transfer design on the lower platen, then lay the Teflon sheet over the top before closing the press.

For Multi-Layered Vinyl Designs

When adding a second or third layer of vinyl, you must protect the layers already pressed. Cover the existing, exposed vinyl with the Teflon sheet before pressing the next layer. This prevents the carrier sheet from leaving an impression and protects the vinyl from direct, excessive heat.

For Double-Sided Garments

To prevent ink from a sublimation print or HTV from bleeding through to the other side of the shirt, place a Teflon sheet inside the garment. This creates an internal barrier between the front and back layers.

Understanding the Trade-offs: Is a Teflon Sheet Always Necessary?

While highly recommended, a Teflon sheet is not a mandatory requirement for every single press. Understanding when it is critical versus optional allows for a more efficient workflow.

When It Is Essential

For sublimation printing, a Teflon sheet (or protective paper) is non-negotiable to prevent ink from turning to gas and permanently staining your platen. It is also crucial for delicate, heat-sensitive fabrics or for any multi-layer vinyl application.

When It Is Merely a Safeguard

For a simple, single-color HTV design on a durable fabric like a 100% cotton t-shirt, you can often get away without one. The vinyl's own carrier sheet provides a degree of protection.

However, given the low cost of a Teflon sheet versus the cost of a ruined garment, using one every time is a best practice that eliminates nearly all risk of error.

Making the Right Choice for Your Goal

Your specific project will determine how critical a Teflon sheet is to your success.

- If your primary focus is professional-quality results on any fabric: Use a Teflon sheet every time to prevent scorching and ensure even heat for a durable, clean transfer.

- If your primary focus is equipment longevity and cleanliness: The sheet is your best defense against the ink and adhesive buildup that can ruin your heat platen and future projects.

- If your primary focus is complex, multi-layer designs: A Teflon sheet is an essential tool for protecting underlying layers as you build your design.

Ultimately, this simple sheet is one of the key differentiators between inconsistent results and consistently professional work.

Summary Table:

| Benefit | Key Function |

|---|---|

| Garment Protection | Prevents scorching and yellowing on delicate fabrics. |

| Platen Guard | Shields the heat press from ink and adhesive residue. |

| Even Heat Distribution | Normalizes temperature for a consistent, durable application. |

| Non-Stick Surface | Ensures a clean release, preventing smudges or peeling. |

Achieve Consistent, Professional Results with KINTEK PTFE Sheets

Just as a Teflon sheet is essential for protecting your heat press and projects, high-performance PTFE components are critical for reliability in demanding industrial applications. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and specialized industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your equipment operates with maximum efficiency and longevity.

Protect your process and enhance your product quality. Contact KINTEK today to discuss your custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What engineering details contribute to the reliability of PTFE Lip Seals? Master the 4 Pillars of Seal Design

- What are the key benefits of using PTFE gaskets for ball valves? Achieve Superior Sealing and Reliability

- How should PTFE be protected during installation? Prevent Leaks and Damage with Proper Handling

- How does PTFE's coefficient of friction compare to other materials? Discover the Slipperiest Solid

- What happens during suspension polymerization for PTFE production? Creating High-Purity Granular Polymer

- How do PTFE and graphite packing compare in terms of corrosion resistance? Selecting the Right Material for Your Application

- How do PTFE expansion bellows benefit pulse dampeners? Achieve Superior Flow Stability and Corrosion Resistance

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal