For demanding industrial applications, custom Teflon (PTFE) rotary shaft seals are the preferred solution because they merge the exceptional material properties of PTFE—like extreme chemical and temperature resistance—with the ability to be precisely engineered for a specific operational challenge. This tailored approach allows them to succeed where standard elastomeric seals would quickly degrade and fail.

The core advantage of custom PTFE seals is not just the raw material, but the ability to enhance its properties with specific fillers and tailor the seal's physical design. This creates a component perfectly matched to the unique stresses of a high-performance environment, ensuring reliability where off-the-shelf parts cannot.

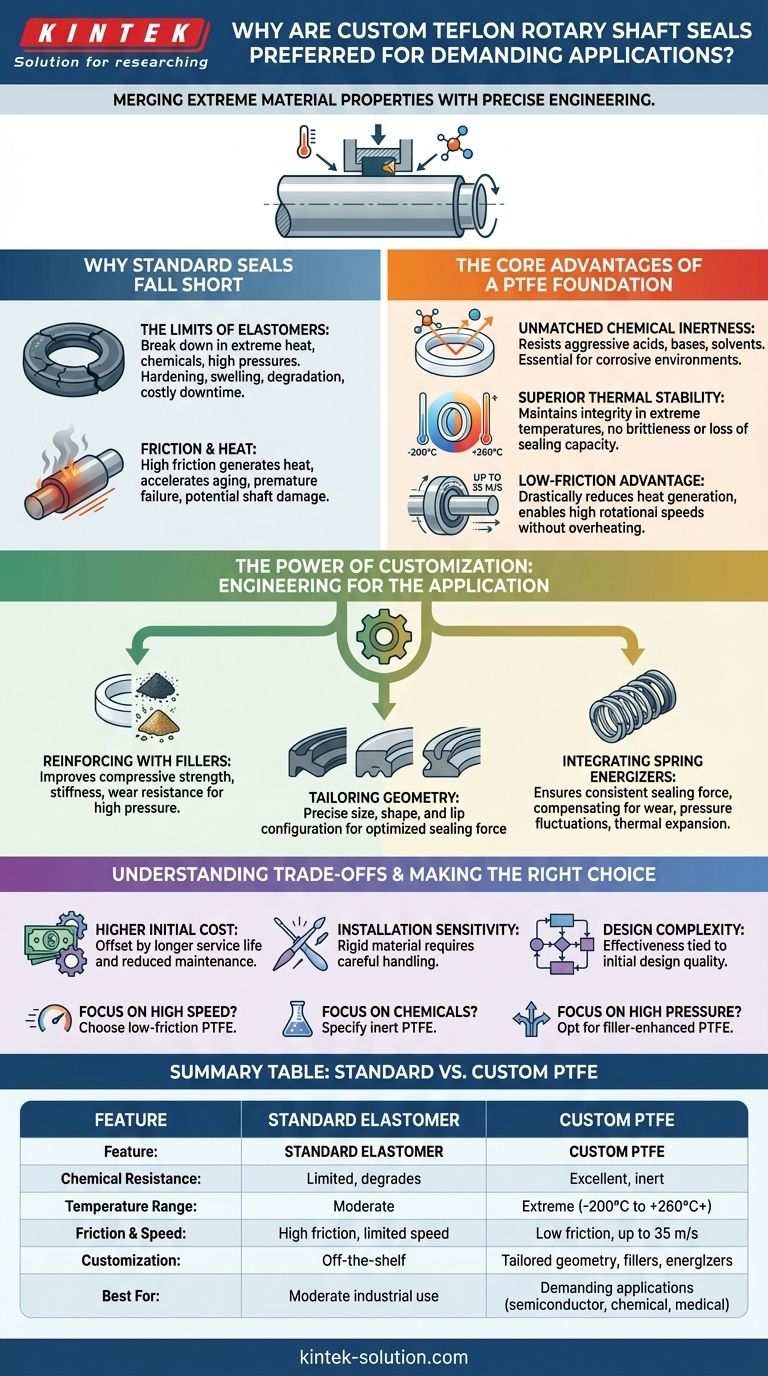

Why Standard Seals Fall Short in Extreme Conditions

To understand the value of custom PTFE seals, we must first recognize the limitations of conventional seals, which are often made from elastomeric (rubber-like) materials.

The Limits of Traditional Elastomers

Standard rubber seals perform well in moderate conditions but break down when faced with extreme heat, aggressive chemicals, or high pressures. These factors cause the material to harden, swell, or degrade, leading to seal failure and costly downtime.

The Problem of Friction and Heat

In high-speed rotating equipment, the friction between a standard seal lip and the shaft generates significant heat. This heat accelerates material aging and wear, causing the seal to fail prematurely and potentially damaging the shaft itself.

The Core Advantages of a PTFE Foundation

PTFE, commonly known by the brand name Teflon, provides a material baseline that fundamentally overcomes the weaknesses of traditional elastomers.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, and solvents. This makes PTFE seals essential in industries like chemical processing, where equipment must reliably contain highly corrosive substances.

Superior Thermal Stability

These seals maintain their integrity and performance across a wide range of temperatures. They can operate in environments far too hot for conventional elastomers without becoming brittle or losing their sealing capability.

The Low-Friction Advantage

PTFE has one of the lowest coefficients of friction of any solid material. This property drastically reduces heat generation, allowing PTFE seals to operate effectively at very high rotational speeds, sometimes up to 35 m/s, without overheating.

The Power of Customization: Engineering for the Application

The true performance of these seals comes from tailoring both the material and the design to the exact needs of the equipment.

Reinforcing PTFE with Fillers

While pure PTFE is impressive, it can be enhanced by blending it with fillers like carbon, glass, or bronze. These additives significantly improve critical properties such as compressive strength, stiffness, and wear resistance, making the seal robust enough for high-pressure and heavy-duty applications.

Tailoring the Seal Geometry

Manufacturers can customize every aspect of the seal's physical design. This includes its precise size and shape, as well as the lip configuration, which is critical for optimizing the sealing force against the shaft under specific operational pressures.

Integrating Spring Energizers

For applications requiring consistent sealing force across a wide range of conditions, a metallic spring can be integrated into the seal design. This "energizer" ensures the seal lip maintains constant contact with the shaft, compensating for wear, pressure fluctuations, and thermal expansion.

Understanding the Trade-offs

While highly effective, custom PTFE seals are a specialized solution with specific considerations.

Higher Initial Cost

The engineering, custom molding, and advanced materials involved mean that custom PTFE seals typically have a higher upfront cost than standard, mass-produced elastomeric seals. However, this cost is often offset by longer service life and reduced maintenance.

Installation Sensitivity

PTFE is a more rigid material than rubber. As a result, these seals can be less forgiving during installation. Care must be taken to avoid scratching or damaging the seal lip, which could compromise its performance.

Design Complexity

Selecting the right blend of PTFE, filler material, and seal geometry requires a clear understanding of the application's specific pressures, temperatures, and media. The effectiveness of the seal is directly tied to the quality of its initial design specification.

Making the Right Choice for Your Application

Choosing the correct seal configuration is critical for maximizing reliability and performance in your machinery.

- If your primary focus is high rotational speed: Choose a low-friction PTFE compound to minimize heat generation and prevent premature wear.

- If your primary focus is aggressive chemical exposure: Specify a PTFE seal for its chemical inertness, ensuring it won't degrade from contact with acids, bases, or solvents.

- If your primary focus is high pressure or heavy loads: Opt for a custom PTFE seal enhanced with fillers like carbon or bronze to increase its compressive strength and wear resistance.

By aligning the seal's material and design to your specific operational challenge, you move from using a generic component to implementing a truly engineered solution.

Summary Table:

| Feature | Standard Elastomer Seals | Custom PTFE Seals |

|---|---|---|

| Chemical Resistance | Limited, degrades with acids/bases | Excellent, inert to most chemicals |

| Temperature Range | Moderate | Extreme (-200°C to +260°C+) |

| Friction & Speed | High friction, limited speed | Low friction, handles up to 35 m/s |

| Customization | Off-the-shelf designs | Tailored geometry, fillers, and energizers |

| Best For | Moderate industrial use | Demanding applications (semiconductor, chemical, medical) |

Ready to solve your toughest sealing challenges? At KINTEK, we specialize in manufacturing custom PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our precision engineering ensures your seals are tailored for extreme conditions, combining chemical inertness, thermal stability, and low friction for maximum reliability. Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications