Beyond the non-stick pan, Polytetrafluoroethylene (PTFE) is one of the most versatile and critical materials in modern industry. Its best-known applications include non-stick coatings for kitchenware, waterproof and breathable membranes like Gore-Tex, and high-performance industrial seals and gaskets used in aggressive chemical environments.

PTFE's wide-ranging applications are not accidental; they are a direct result of its unique and powerful combination of three core properties: extreme chemical inertness, an exceptionally low coefficient of friction, and excellent electrical insulation.

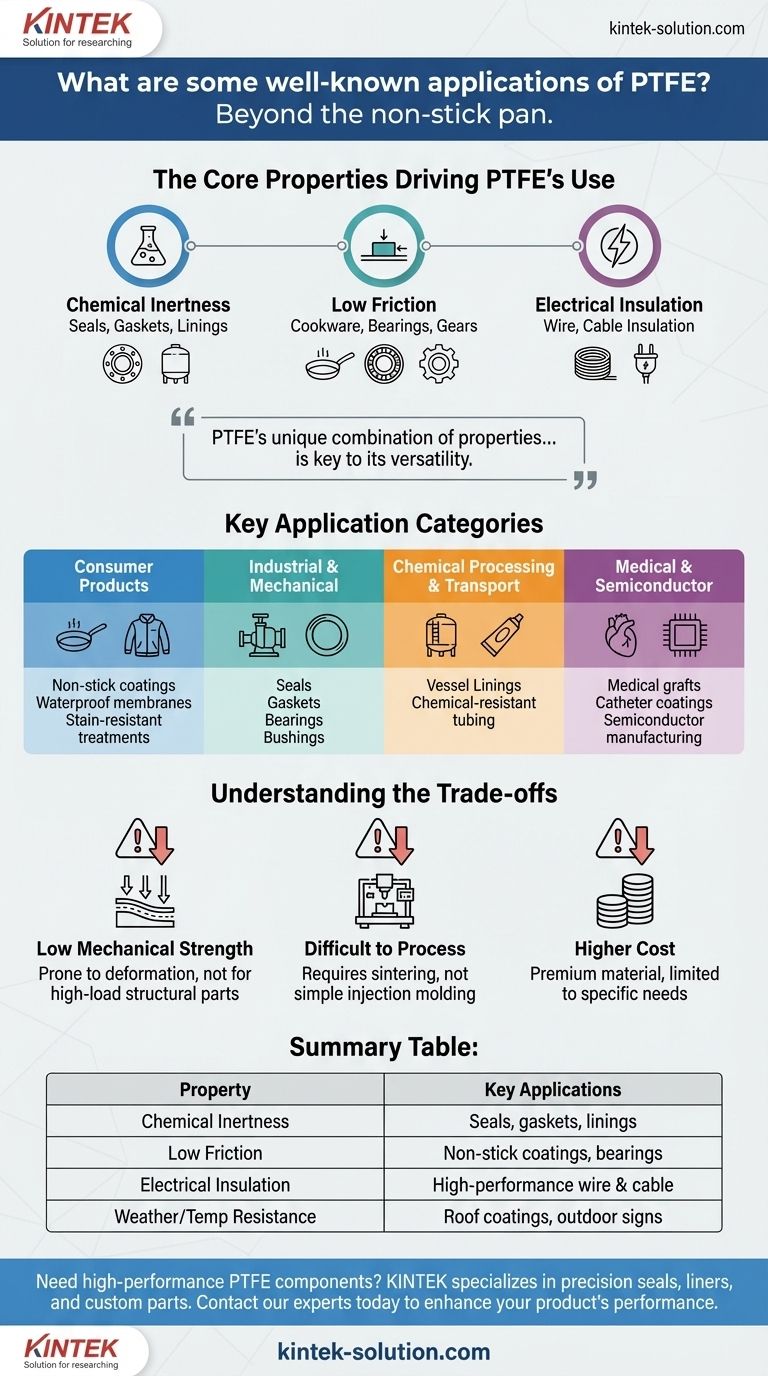

The Core Properties Driving PTFE's Use

To understand where PTFE is used, you must first understand why. The material's value stems from a few key characteristics that make it the best—or only—choice for certain demanding jobs.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all chemicals, solvents, and corrosive agents. This non-reactivity makes it indispensable for handling aggressive substances.

This property is why it's used for seals, gaskets, and linings in chemical processing equipment, pipes, and tanks. It ensures the integrity of the system and prevents contamination.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material, giving it its famous "non-stick" quality.

While this is key for cookware, it is even more critical in industrial machinery. It's used for self-lubricating bearings, bushings, gears, and slide plates, reducing wear and energy consumption.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with very high dielectric strength, meaning it can withstand strong electric fields without breaking down.

This makes it a top choice for wire and cable insulation, especially in demanding aerospace and computer applications where signal integrity and safety are paramount.

Weather and Temperature Resistance

PTFE is highly resistant to UV radiation and performs reliably across a wide range of temperatures, making it suitable for long-term outdoor use.

You will find it used in protective coatings for the roofs of large venues like airports and stadiums or as a weatherproofing material for outdoor signs.

A Look at Key Application Categories

PTFE's properties allow it to serve critical functions across vastly different industries, from the home kitchen to outer space.

In Consumer Products

This is where most people encounter PTFE. Its non-stick and hydrophobic (water-repelling) properties are the main drivers.

Applications include non-stick coatings on pots and pans, stain-resistant treatments for fabrics and carpets, and waterproof membranes in high-performance outdoor gear.

In Industrial and Mechanical Systems

In manufacturing and machinery, PTFE's low-friction and sealing capabilities are essential for efficiency and reliability.

It's molded into seals, O-rings, gaskets, and valve components to prevent leaks in pumps and pipes. It's also machined into piston rings, bearings, and bushings to reduce friction in moving parts.

In Chemical Processing and Transport

The chemical industry relies on PTFE's inertness to safely handle corrosive materials.

It's used to create linings for vessels and tanks, as well as chemical-resistant tubing and laboratory containers.

In Medical and Semiconductor Fields

In high-purity environments, PTFE's non-reactive and biocompatible nature is a significant advantage.

It is used as a graft material in medical procedures, for coatings on catheters, and in semiconductor manufacturing where its resistance to strong acids is crucial.

Understanding the Trade-offs

While incredibly useful, PTFE is not the solution for every problem. Its unique properties come with certain limitations that are important to recognize.

Relatively Low Mechanical Strength

PTFE is a relatively soft material. It can be prone to "creep," meaning it can slowly deform over time when under a constant load. It is not suitable for high-load structural components on its own.

Difficult to Process

Unlike many common plastics that can be easily melt-processed and injection molded, PTFE must be processed using more complex and costly techniques like sintering.

Higher Cost

Compared to commodity plastics like polyethylene or polypropylene, PTFE is a premium material with a significantly higher cost, restricting its use to applications where its unique properties are truly necessary.

Making the Right Choice for Your Goal

Selecting a material depends entirely on the problem you are trying to solve. PTFE is a specialist material that excels in specific conditions.

- If your primary focus is reducing friction: PTFE is the gold standard for self-lubricating bearings, gears, and creating non-stick surfaces.

- If your primary focus is chemical resistance: It is the definitive material for seals, gaskets, and linings in aggressive chemical environments.

- If your primary focus is electrical insulation: Its excellent dielectric properties make it ideal for high-performance wiring in critical applications like aerospace.

- If your primary focus is biocompatibility: Its inertness allows it to be used for medical implants and devices like vascular grafts.

Ultimately, PTFE's value lies in its ability to perform reliably where other materials would quickly fail.

Summary Table:

| Property | Key Applications |

|---|---|

| Chemical Inertness | Seals, gaskets, chemical tank linings |

| Low Friction | Non-stick coatings, bearings, bushings |

| Electrical Insulation | High-performance wire & cable insulation |

| Weather/Temp Resistance | Roof coatings, outdoor weatherproofing |

Need high-performance PTFE components tailored to your specific requirements? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom parts for the semiconductor, medical, laboratory, and industrial sectors. We combine exacting production standards with flexible fabrication—from prototypes to high-volume orders—to deliver reliability in the most demanding environments. Contact our experts today to discuss your project and discover how our PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is PTFE and what is it commonly known as? The Ultimate Guide to Teflon & Its Uses

- What role does PTFE play in automotive applications? Enhance Efficiency and Reliability in EVs and Engines

- How does the electronegativity of fluorine affect PTFE's structure? The Key to Its Unmatched Chemical Resistance

- How is PTFE granular resin produced? The Key to Creating Robust, Machinable Components

- What is PTFE and why is it significant? Unlock the Power of a High-Performance Polymer

- What is PTFE's most familiar household application? Discover the Versatile Material Behind Non-Stick Cookware

- What is the coefficient of friction of PTFE? Unlocking Its Slippery Secrets for Your Designs

- What industries commonly use Teflon material? Unlocking Versatility Across Sectors