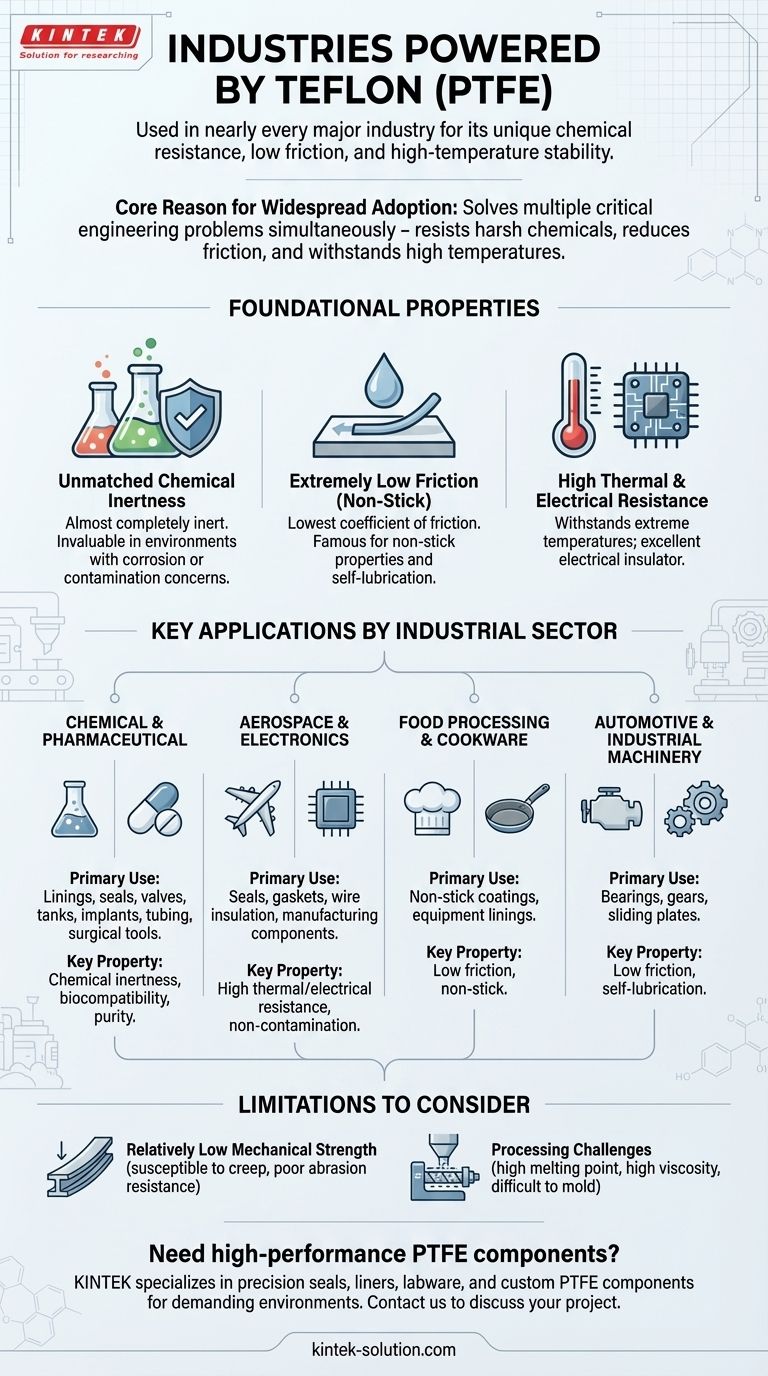

In short, Teflon is used in nearly every major industry imaginable. Its unique properties make it a foundational material in sectors ranging from aerospace, automotive, and medical to chemical processing, electronics, and food manufacturing. The material's versatility stems from a combination of chemical resistance, extremely low friction, and high-temperature stability found in few other polymers.

The core reason for Teflon's widespread adoption is not just that it performs one function well, but that it solves multiple critical engineering problems simultaneously—it can resist harsh chemicals while reducing friction in high-temperature environments, a combination that is indispensable.

Why Teflon is a Foundational Material Across Industries

Teflon is the brand name for Polytetrafluoroethylene (PTFE), a synthetic polymer with a unique set of characteristics. Understanding these core properties explains why it has become so essential across such a diverse range of applications.

Unmatched Chemical Inertness

Teflon is almost completely inert, meaning it does not react with the vast majority of chemicals. This property makes it invaluable in environments where corrosion or contamination is a major concern.

This is critical in the chemical processing industry for lining pipes, valves, reactors, and tanks. It is also essential in the medical and pharmaceutical fields for implants, tubing, and equipment that require absolute purity and biocompatibility.

Extremely Low Friction (Non-Stick)

Teflon has one of the lowest coefficients of friction of any solid material, which is why it is famous for its non-stick properties. This "slipperiness" is a significant engineering advantage.

In food processing and cookware, this enables non-stick surfaces. In industrial machinery, it is used to create self-lubricating bearings, gears, and sliding plates that reduce wear and improve efficiency in everything from automotive engines to power tools.

High Thermal and Electrical Resistance

Teflon can withstand a wide range of temperatures, from very low to high heat, without degrading. It is also an excellent electrical insulator.

These properties are vital in aerospace, where it is used for seals, gaskets, and wire insulation that must perform reliably under extreme temperature fluctuations. In the electronics and semiconductor industries, it serves as a high-performance insulator for wiring and a non-contaminating material for manufacturing equipment.

Understanding the Material's Limitations

While incredibly versatile, Teflon (PTFE) is not a perfect solution for every problem. Being an objective advisor means acknowledging its trade-offs.

Relatively Low Mechanical Strength

Compared to metals or other engineering plastics, Teflon is relatively soft. It can be susceptible to creep (deforming under load) and has poor abrasion resistance on its own.

For this reason, it is often used as a coating or a component within a larger assembly rather than as a primary structural material.

Processing Challenges

Teflon has a very high melting point and viscosity, which makes it difficult to process using conventional plastic manufacturing methods like injection molding.

This often requires specialized techniques like compression molding and sintering, which can increase manufacturing complexity and cost compared to more common polymers.

Key Applications by Industrial Sector

To apply this knowledge, consider the primary problem you are trying to solve. Teflon's use in any given industry is almost always tied to one of its core strengths.

- For handling aggressive chemicals: Its inertness makes it essential for linings and seals in the chemical, pharmaceutical, and oil & gas industries.

- For reducing friction and wear: Its low-friction surface is critical for bearings in industrial machinery, non-stick coatings in food processing, and reducing friction in automotive parts.

- For high-temperature and electrical demands: Its stability is vital for seals in aerospace and high-frequency insulation in the electronics sector.

- For biocompatibility and purity: Its non-reactive nature is crucial for implants, surgical tools, and tubing in the medical field.

Ultimately, Teflon's value lies in its ability to perform reliably where other materials fail.

Summary Table:

| Industry | Primary Use of Teflon (PTFE) | Key Property Leveraged |

|---|---|---|

| Chemical Processing | Linings, seals, valves, tanks | Chemical inertness |

| Medical & Pharmaceutical | Implants, tubing, surgical tools | Biocompatibility, purity |

| Aerospace | Seals, gaskets, wire insulation | High thermal/electrical resistance |

| Food Processing | Non-stick coatings, equipment linings | Low friction, non-stick |

| Electronics & Semiconductor | Wiring insulation, manufacturing components | Electrical insulation, non-contamination |

| Automotive & Industrial Machinery | Bearings, gears, sliding plates | Low friction, self-lubrication |

Need high-performance PTFE components tailored to your industry's demands? At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial applications. Whether you require prototypes or high-volume orders, our expertise ensures reliability in the most demanding environments. Contact us today to discuss your project and discover how our solutions can enhance your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability