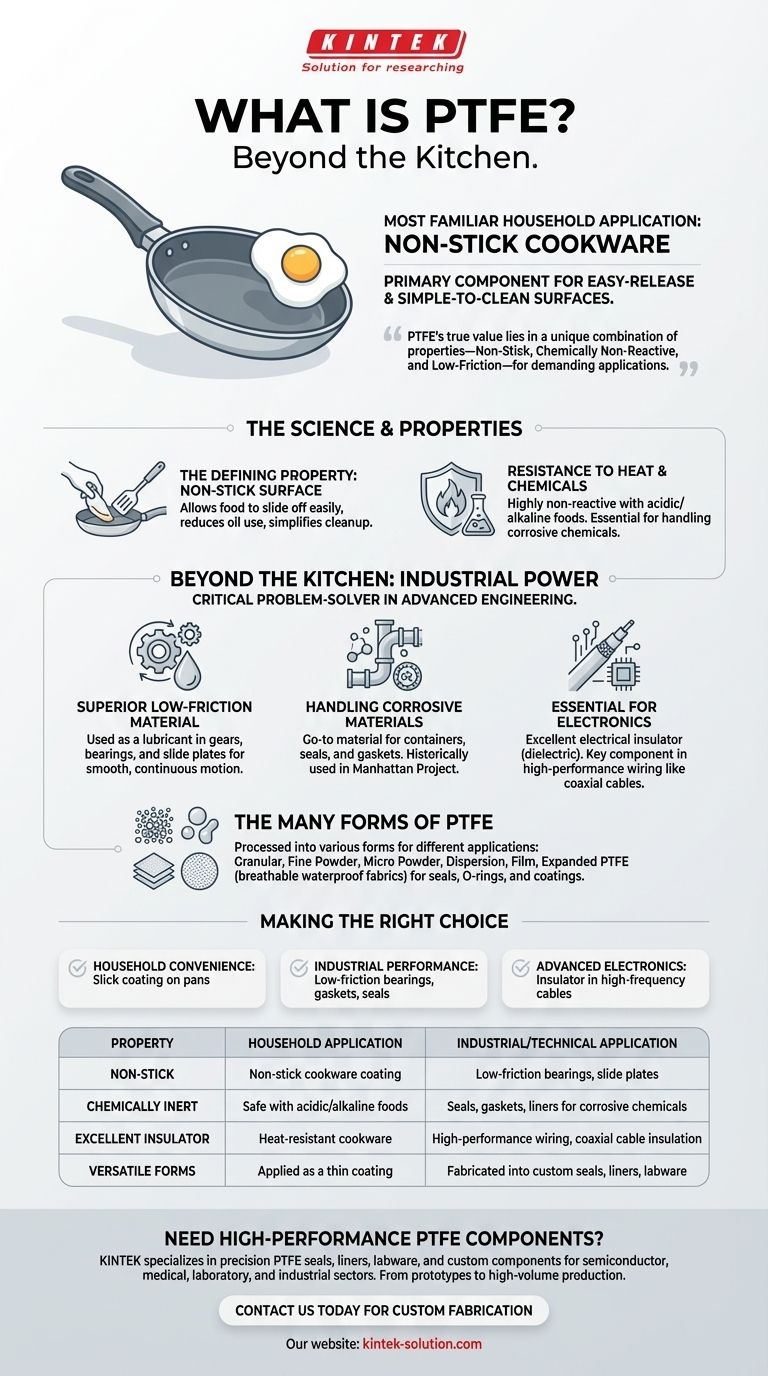

Without a doubt, Polytetrafluoroethylene (PTFE) is most famously known for its application as the non-stick coating on household cookware. This material is the primary component that gives pans, skillets, and baking trays their characteristic easy-release and simple-to-clean surfaces.

While its fame comes from the kitchen, PTFE's true value lies in a unique combination of properties—being non-stick, chemically non-reactive, and low-friction—that makes it an essential material in demanding industrial, chemical, and electronic applications.

The Science Behind the Non-Stick Pan

To understand why PTFE is so versatile, we first need to look at the properties that make it a star in the kitchen. Its household familiarity is a direct result of its unique molecular structure.

The Defining Property: Non-Stick Surface

The primary reason PTFE is used for cookware is its excellent non-stick properties. This characteristic allows food to slide off surfaces easily, reducing the need for oils and simplifying cleanup.

Resistance to Heat and Chemicals

PTFE is also highly non-reactive. This inertness prevents it from reacting with acidic or alkaline foods during cooking. The same property makes it invaluable for handling highly corrosive chemicals in industrial settings.

Beyond the Kitchen: PTFE's Industrial Power

The same characteristics that prevent an egg from sticking to a pan make PTFE a critical problem-solver in advanced engineering and science. Its applications extend far beyond household goods.

A Superior Low-Friction Material

Because of its slippery nature, PTFE is widely used as a lubricant to reduce friction between moving parts. You will find it in industrial applications like gears, bearings, and slide plates where smooth, continuous motion is critical.

Handling Corrosive Materials

Due to its non-reactive nature, PTFE is a go-to material for containers, pipework, seals, and gaskets that come into contact with aggressive chemicals. One of its earliest high-stakes uses was coating valves and seals in the uranium enrichment plants of the Manhattan Project.

Essential for Electronics

PTFE is an excellent electrical insulator, known for its dielectric properties. This makes it a key component in computer applications, particularly for insulating high-performance wiring like coaxial cables and hookup wires.

The Many Forms of PTFE

PTFE is not a single, uniform substance. It is processed into various forms to suit its intended application, highlighting its incredible versatility.

From Powders to Films

Engineers can work with several common types of PTFE, including Granular, Fine Powder, and Micro Powder forms. It can also be manufactured into Dispersion, Film, and Expanded PTFE (like that used in breathable waterproof fabrics) to create everything from seals and O-rings to specialized surface coatings.

Making the Right Choice for Your Goal

Understanding the context is key to identifying and appreciating the role of PTFE. Its application changes dramatically based on the performance requirements of the environment.

- If your primary focus is household convenience: You will recognize PTFE as the dark, slick coating on non-stick pans and bakeware.

- If your primary focus is industrial performance: You will find PTFE in low-friction bearings, chemical-resistant gaskets, and protective seals.

- If your primary focus is advanced electronics: PTFE serves as a critical insulator in high-frequency cables where signal integrity is paramount.

Ultimately, PTFE's journey from a top-secret wartime material to a kitchen staple demonstrates how truly advanced material science quietly improves both our daily lives and our most critical technologies.

Summary Table:

| Property | Household Application | Industrial/Technical Application |

|---|---|---|

| Non-Stick | Non-stick cookware coating | Low-friction bearings and slide plates |

| Chemically Inert | Safe with acidic/alkaline foods | Seals, gaskets, and liners for corrosive chemicals |

| Excellent Insulator | Heat-resistant cookware | High-performance wiring and coaxial cable insulation |

| Versatile Forms | Applied as a thin coating | Fabricated into custom seals, liners, and labware |

Need high-performance PTFE components tailored to your exact requirements? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures material integrity and performance in demanding environments.

Contact us today to discuss your project and benefit from our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments