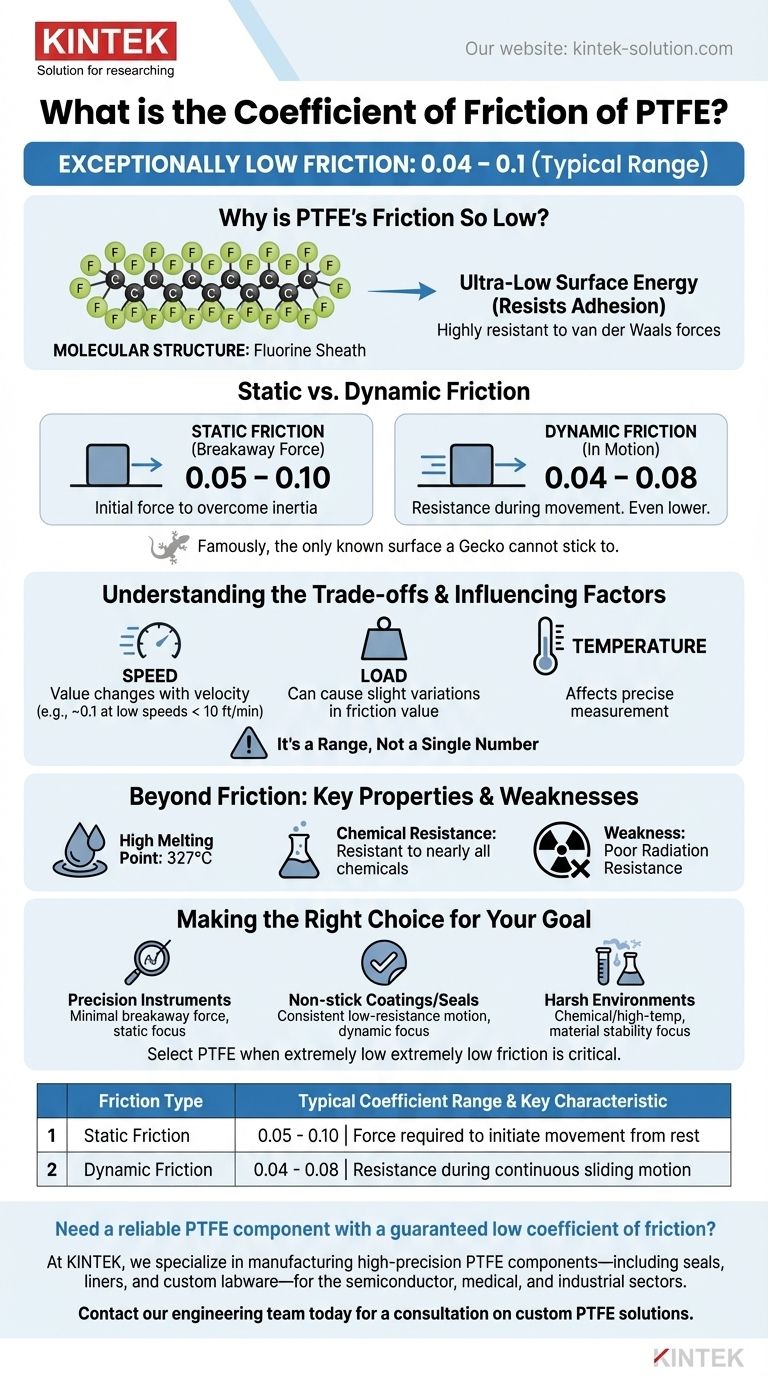

The coefficient of friction for Polytetrafluoroethylene (PTFE) is exceptionally low, typically cited in a range between 0.04 and 0.1. This value is not a single constant but varies depending on whether the material is in motion (dynamic) or at rest (static). Factors such as load, speed, and temperature also influence the precise measurement.

The core reason for PTFE's "slipperiness" is its unique molecular structure. This structure creates an ultra-low-energy surface that resists adhesion, making it one of the most frictionless solid materials known.

Why is PTFE's Friction So Low?

The incredibly low friction of PTFE isn't a fluke; it's a direct result of its chemical makeup and physical properties. Understanding this helps clarify why it's chosen for so many demanding applications.

The Role of Molecular Structure

PTFE consists of a long carbon chain completely sheathed by fluorine atoms. This fluorine sheath is extremely stable and non-reactive.

This structure creates an ultra-low surface energy, which means other materials have very little to "grab" onto. It is highly resistant to the weak intermolecular attractions known as van der Waals forces.

Static vs. Dynamic Friction

Friction is measured in two states: static (the force needed to start movement) and dynamic (the resistance during movement).

PTFE's static coefficient of friction typically ranges from 0.05 to 0.10. This is the initial force required to overcome inertia.

Its dynamic coefficient of friction is even lower, usually between 0.04 and 0.08. Once in motion, PTFE surfaces slide against each other with minimal resistance.

A Surface That Resists Sticking

This low-friction property makes PTFE one of the best non-stick materials available.

It is famously the only known surface a Gecko cannot stick to. This property also makes it nearly impossible to bond PTFE to other materials using conventional adhesives.

Understanding the Trade-offs and Influencing Factors

While the headline number is impressive, a technical advisor must consider the context. The coefficient of friction is not an absolute value and can be influenced by the operating environment.

It's a Range, Not a Single Number

You should never assume a single value for PTFE's friction. Always design for the range of possibilities based on your application's specific conditions.

The Impact of Speed and Load

The friction coefficient can change with velocity. At very low speeds (under 10 ft/min), the value is often cited closer to 0.1.

Similarly, the load applied to the surface and the finish of the mating material can cause slight variations in the friction value.

Beyond Friction: Other Key Properties

PTFE's usefulness comes from a combination of properties. It has a high melting point (327°C) and is resistant to nearly all chemicals.

However, it has notable weaknesses. PTFE exhibits poor radiation resistance, which can limit its use in certain aerospace or nuclear applications.

Making the Right Choice for Your Goal

Selecting a material requires balancing its benefits against its limitations. Use these guidelines to determine if PTFE is the optimal choice.

- If your primary focus is minimal breakaway force: PTFE's low static friction makes it ideal for precision instruments and bearings that must move from rest with very little effort.

- If your primary focus is consistent, low-resistance motion: Its even lower dynamic friction is perfect for non-stick coatings, seals, and sliding components in continuous operation.

- If your application involves harsh chemicals or high temperatures: PTFE's chemical inertness and high melting point make it a superior choice over other low-friction polymers that would degrade.

Ultimately, you should select PTFE when an extremely low coefficient of friction is the most critical design driver for your project.

Summary Table:

| Friction Type | Typical Coefficient Range | Key Characteristic |

|---|---|---|

| Static Friction | 0.05 - 0.10 | Force required to initiate movement from rest |

| Dynamic Friction | 0.04 - 0.08 | Resistance during continuous sliding motion |

Need a reliable PTFE component with a guaranteed low coefficient of friction?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise ensures your designs benefit from PTFE's exceptional slipperiness, chemical resistance, and thermal stability.

Let us help you optimize your application. Contact our engineering team today for a consultation on custom PTFE solutions, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments