In short, PTFE is Polytetrafluoroethylene, a synthetic polymer made of carbon and fluorine atoms. While that is its technical name, it is far more commonly known by the brand name Teflon, especially for its use as a non-stick coating on cookware.

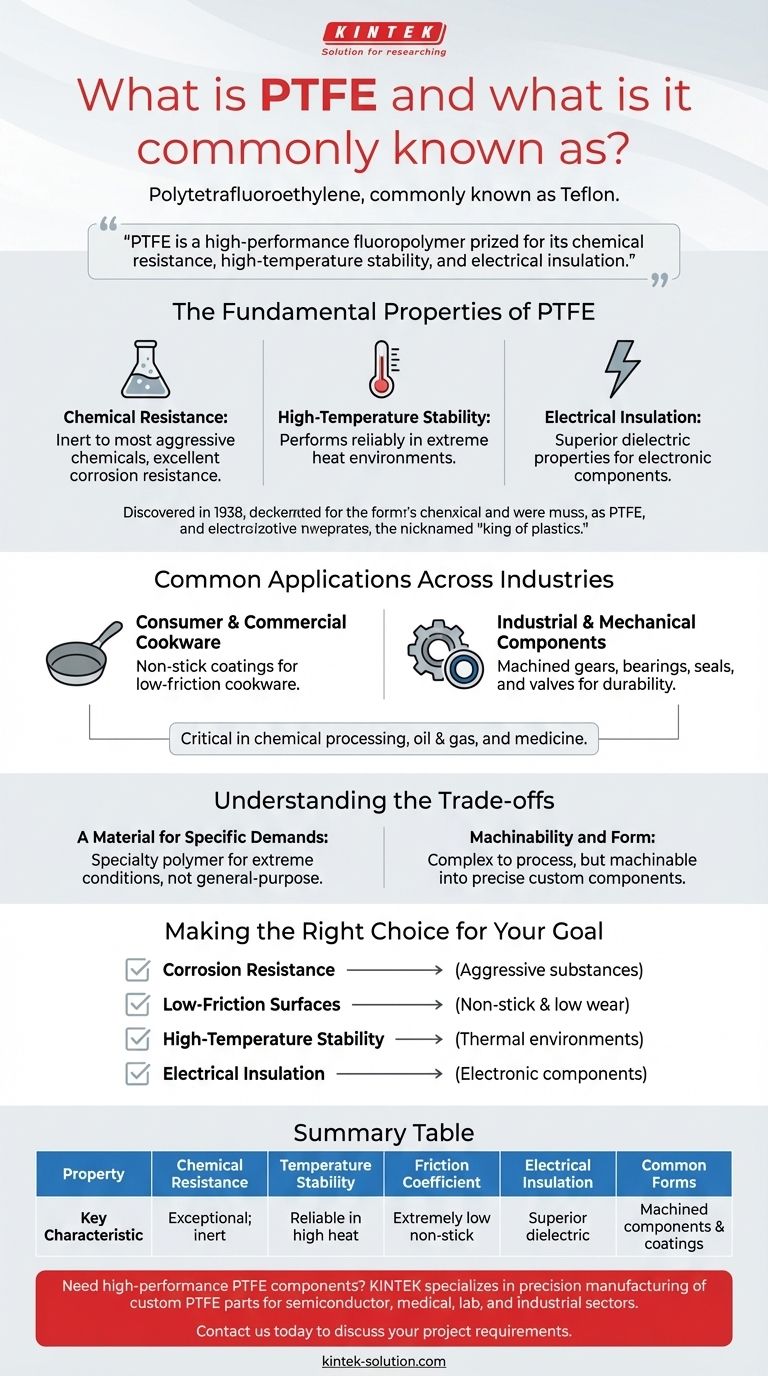

PTFE, widely known as Teflon, is a high-performance fluoropolymer prized not just for non-stick surfaces, but for an exceptional combination of chemical resistance, high-temperature stability, and electrical insulation that makes it a critical material in demanding industrial applications.

The Fundamental Properties of PTFE

PTFE was first discovered in 1938. Its unique molecular structure gives it a set of properties that make it incredibly valuable, earning it the nickname the "king of plastics" in some circles.

Chemical Composition

PTFE is a fluorocarbon-based polymer. It is created by polymerizing tetrafluoroethylene, resulting in a molecule with a long chain of carbon atoms completely surrounded by fluorine atoms.

Unmatched Chemical Resistance

The strong carbon-fluorine bonds make PTFE exceptionally non-reactive. It has excellent chemical stability and is one of the best materials in the world for corrosion resistance, capable of withstanding a vast range of aggressive chemicals.

High-Temperature Capability

This material maintains its properties across a wide range of temperatures. Its ability to perform reliably in high-temperature environments makes it suitable for many industrial processes where other plastics would fail.

Enhanced Electrical Properties

PTFE is an excellent electrical insulator. This characteristic makes it a go-to material for insulating wires, cables, and other electronic components, especially in high-performance applications.

Common Applications Across Industries

While most people associate PTFE with kitchen pans, its true impact is felt across a wide range of technical and industrial fields. Its unique properties allow it to solve problems that other materials cannot.

Consumer and Commercial Cookware

The most famous application is as the non-stick coating on pots, pans, and other cookware, a direct result of its low-friction surface.

Industrial and Mechanical Components

In industrial settings, PTFE is machined into custom parts that require durability and low friction. Common examples include gears, bearings, slide plates, seals, and distribution valves.

Critical Sector Use

Because of its chemical inertness and stability, PTFE is essential in sectors like chemical processing, oil and gas, and medicine. Its use in electrical insulation is also critical for the electronics industry.

Understanding the Trade-offs

While its properties are exceptional, it's important to understand the context of PTFE's "king of plastics" status.

A Material for Specific Demands

PTFE is not a general-purpose plastic used for everyday items like bottles or packaging. It is a specialty polymer chosen specifically for its ability to perform under extreme conditions—be it chemical, thermal, or electrical stress.

Machinability and Form

Unlike many common plastics that are easily molded, PTFE's properties can make it more complex to process. However, it can be effectively machined into precise, custom components like backup rings or valve seats for highly specific applications.

Making the Right Choice for Your Goal

Understanding the core strengths of PTFE helps clarify why it is chosen for a particular application.

- If your primary focus is corrosion resistance: PTFE is one of the most chemically inert and resistant materials available for handling aggressive substances.

- If your primary focus is low-friction surfaces: It provides the quintessential non-stick and low-wear surface for everything from cookware to industrial bearings.

- If your primary focus is high-temperature stability: It is a reliable choice for components that must operate in demanding thermal environments.

- If your primary focus is electrical insulation: Its superior dielectric properties make it a top-tier choice for insulating critical electronic and electrical components.

Ultimately, PTFE's value lies in its unique ability to solve a specific set of extreme engineering challenges.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Exceptional; inert to most aggressive chemicals |

| Temperature Stability | Performs reliably in high-temperature environments |

| Friction Coefficient | Extremely low, providing a non-stick surface |

| Electrical Insulation | Superior dielectric properties |

| Common Forms | Machined components (seals, bearings, liners), coatings |

Need high-performance PTFE components for your application?

KINTEK specializes in the precision manufacturing of custom PTFE parts—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get components that deliver unmatched chemical resistance, thermal stability, and reliability.

Contact us today to discuss your project requirements and see how our PTFE solutions can meet your most demanding specifications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications