In high-performance sealing, PTFE-based components are chosen for their unique combination of properties. The most common components include piston and rod seals to prevent fluid leakage, rod wipers to keep systems clean, bearing guide strips for alignment, backup rings to support primary seals under pressure, and ball valve seats for chemically demanding flow control applications.

The true value of PTFE in sealing is not just one characteristic, but its rare combination of extreme chemical inertness, exceptionally low friction, and a vast operating temperature range, making it a foundational material for reliability in harsh environments.

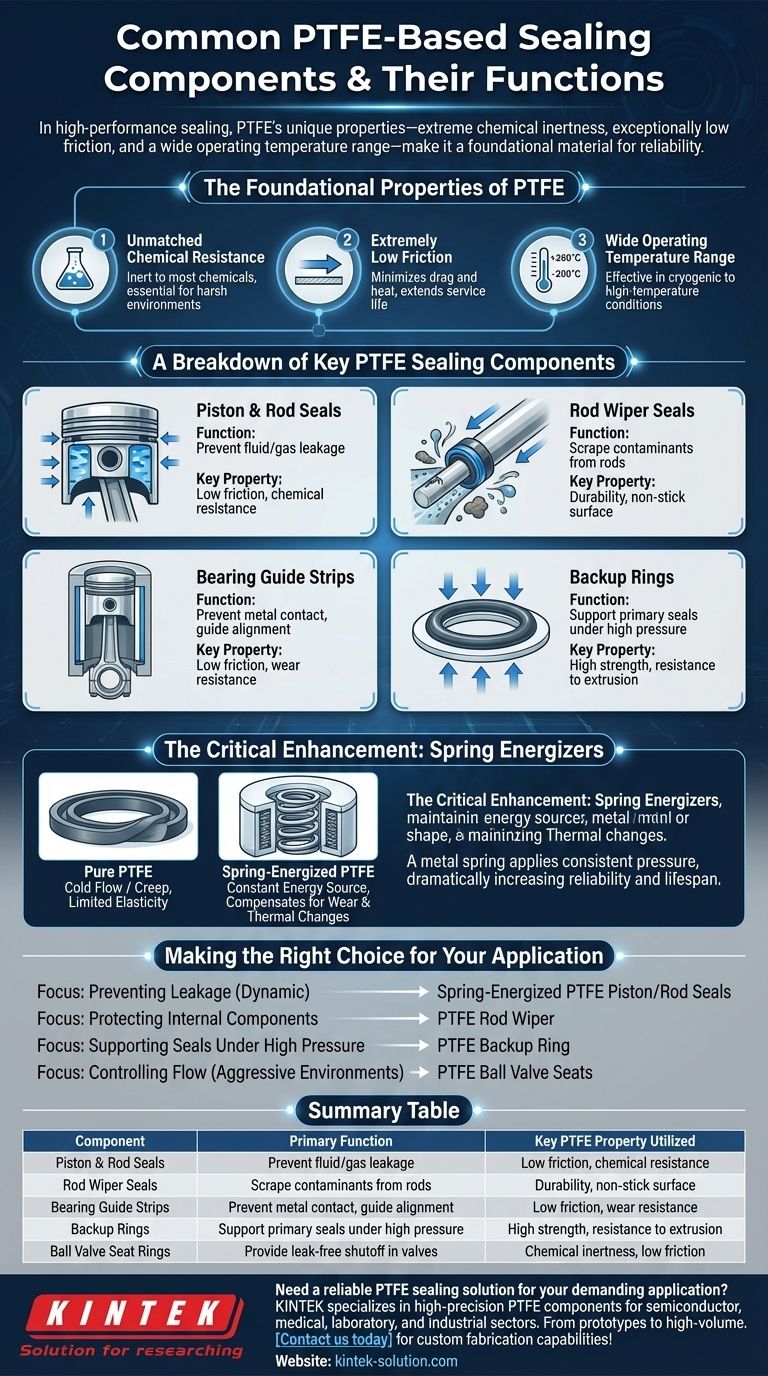

The Foundational Properties of PTFE

Before examining specific components, it's crucial to understand why PTFE (Polytetrafluoroethylene) is such a uniquely effective sealing material. Its molecular structure, a chain of carbon atoms shielded by fluorine atoms, is the source of its power.

Unmatched Chemical Resistance

PTFE is virtually inert and compatible with almost all industrial chemicals. This makes it an essential choice for seals in chemical processing, pharmaceuticals, and other industries where corrosive media are present.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-stick property minimizes drag and heat generation in dynamic applications, leading to less wear and a longer service life.

Wide Operating Temperature Range

This material maintains its key properties across an exceptionally broad temperature spectrum. It remains effective in cryogenic conditions (down to -200°C) and at high temperatures (up to +260°C), a versatility few other polymers can match.

A Breakdown of Key PTFE Sealing Components

Different PTFE components are engineered to solve specific challenges within a hydraulic or pneumatic system. Each leverages the core properties of the material in a distinct way.

Piston and Rod Seals

These are the primary seals responsible for preventing fluid or gas from leaking past a piston or rod. PTFE's low friction is critical here, as it allows for smooth, efficient movement while maintaining a tight seal, reducing energy loss and preventing component wear.

Rod Wiper Seals

A rod wiper's function is purely protective. It is designed to scrape contaminants like dust, dirt, and moisture from a piston rod as it retracts into a system. This prevents external debris from damaging internal components and compromising the primary seals.

Bearing Guide Strips

Also known as wear rings, these components prevent metal-to-metal contact between a piston or rod and the cylinder bore. They guide the moving parts, absorb side loads, and ensure proper alignment, which is critical for the longevity of the entire sealing system.

Backup Rings

Backup rings are not designed to be the primary sealing element. Instead, they are installed behind a primary seal (often an elastomeric O-ring) to prevent it from extruding into the clearance gap under high pressure. This allows the system to operate at higher pressures than it otherwise could.

Ball Valve Seat Rings

In a ball valve, the seat ring creates the seal against the ball to stop flow. PTFE is ideal for this role due to its chemical resistance and low friction, which ensures a tight, leak-free shutoff and allows the valve to be operated easily without excessive torque.

The Critical Enhancement: Spring Energizers

While PTFE has exceptional properties, it is also a relatively soft material. In demanding applications, this softness must be addressed to ensure a consistent and reliable seal.

The Challenge of Pure PTFE

Under load, pure PTFE can be susceptible to "cold flow" or creep, which can diminish its sealing force over time. It also has limited elasticity, meaning it may not always return to its original shape.

The Solution: The Spring Energizer

To overcome these limitations, many PTFE seals are spring-energized. A corrosion-resistant metal spring is fitted inside the PTFE jacket. This spring acts as a constant energy source, applying consistent pressure to the sealing lips.

The spring provides the necessary pre-tightening force for an effective seal at low pressures. Crucially, it also compensates for seal wear, thermal changes, and minor hardware misalignments, dramatically increasing the seal's reliability and lifespan.

Making the Right Choice for Your Application

Selecting the correct component is a matter of matching its function to your system's primary need.

- If your primary focus is preventing leakage in dynamic systems: Your solution involves spring-energized PTFE piston or rod seals, which provide a durable, low-friction barrier.

- If your primary focus is protecting internal components from external contaminants: A PTFE rod wiper is the dedicated component for this defensive role.

- If your primary focus is supporting a primary seal under high pressure: A PTFE backup ring is the necessary component to prevent seal extrusion and failure.

- If your primary focus is controlling flow in a chemically aggressive environment: Look to PTFE ball valve seats for reliable, low-torque sealing performance.

By understanding how these components leverage PTFE's unique properties, you can engineer a more robust and reliable sealing system for any demanding application.

Summary Table:

| Component | Primary Function | Key PTFE Property Utilized |

|---|---|---|

| Piston & Rod Seals | Prevent fluid/gas leakage | Low friction, chemical resistance |

| Rod Wiper Seals | Scrape contaminants from rods | Durability, non-stick surface |

| Bearing Guide Strips | Prevent metal contact, guide alignment | Low friction, wear resistance |

| Backup Rings | Support primary seals under high pressure | High strength, resistance to extrusion |

| Ball Valve Seat Rings | Provide leak-free shutoff in valves | Chemical inertness, low friction |

Need a reliable PTFE sealing solution for your demanding application? KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures optimal performance in harsh environments. Contact us today to discuss your specific needs and leverage our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common applications of PTFE bars? Key Uses in High-Performance Industries

- In which industries is RPTFE particularly suitable for throttle valves? Ensure Purity and Durability

- What makes PTFE valuable for food and beverage industry applications? Boost Efficiency & Safety

- What are the key advantages of using PTFE envelope gaskets? Superior Sealing for Aggressive Chemical & High-Pressure Applications

- What are the key properties of PTFE gaskets? Unlock Superior Sealing in Harsh Industrial Environments

- What precautions should be taken when installing PTFE O-rings? Avoid Permanent Damage and Seal Failure

- What new technologies are being applied to PTFE O-ring seals? Enhance Performance with Nanomaterials & 3D Printing

- What material is commonly used for lining valves, and what are its properties? Discover the Power of PTFE Liners