In the food and beverage industry, Polytetrafluoroethylene (PTFE) is highly valued for its unique combination of properties. Its non-stick surface, high heat tolerance, extreme chemical resistance, and the availability of food-safe grades make it an ideal material for direct contact with consumable products and for use in demanding processing environments.

While its famous non-stick quality is the most visible benefit, PTFE's true value lies in its ability to create a highly stable, inert, and low-friction barrier between processing equipment and the food itself. This combination directly translates to increased operational efficiency, enhanced safety, and reduced maintenance costs.

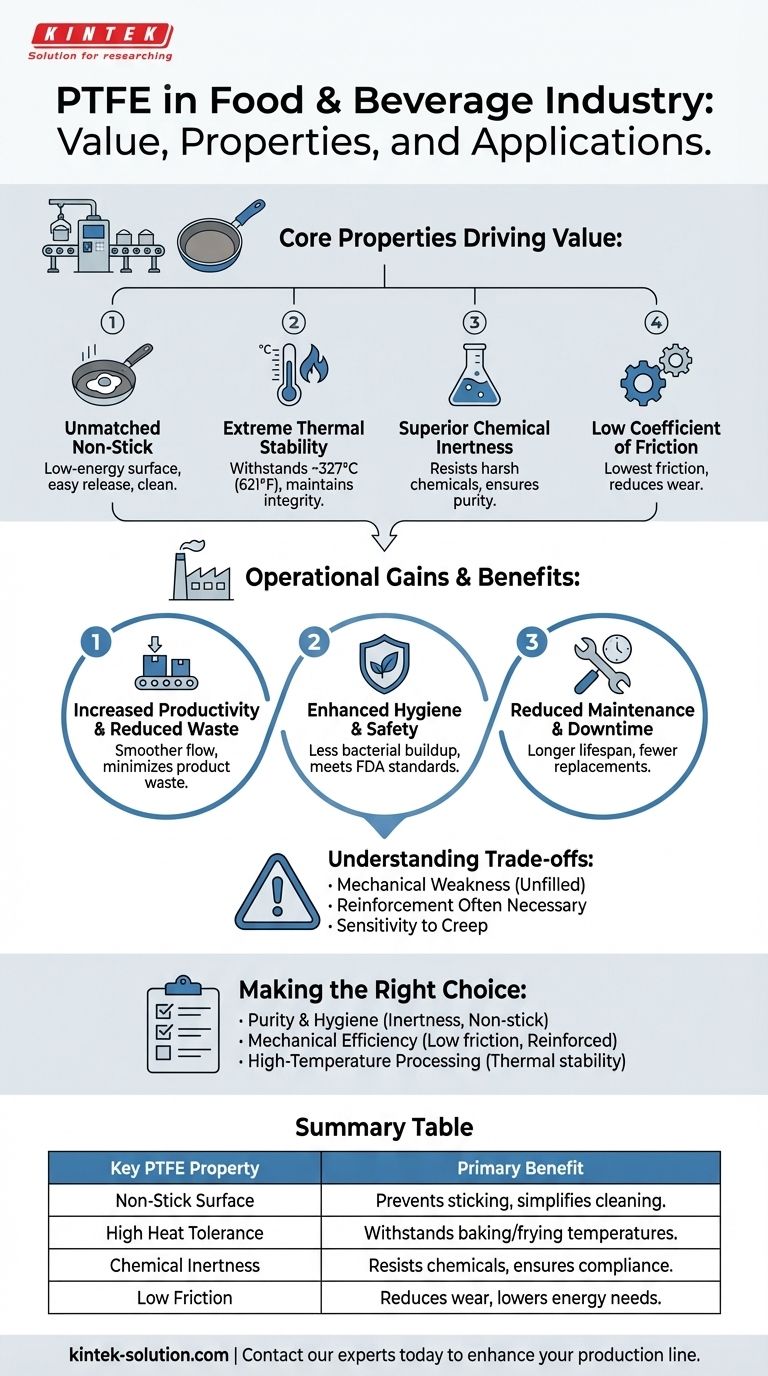

The Core Properties Driving PTFE's Value

The widespread adoption of PTFE is not based on a single feature, but on the synergy of several high-performance characteristics. Each one solves a distinct challenge common in food and beverage production.

Unmatched Non-Stick Performance

PTFE has an exceptionally low-energy surface, which means other substances, including sticky food products, struggle to adhere to it. This non-wetting property ensures an easy and clean release of products from cooking surfaces, molds, and conveyor belts.

Extreme Thermal Stability

With a melting point around 327°C (621°F), PTFE can withstand the high temperatures required in baking, frying, and other cooking processes without degrading. This stability ensures the material maintains its integrity through repeated thermal cycles.

Superior Chemical Inertness

PTFE is resistant to nearly all chemicals, including the aggressive cleaning agents and acidic or alkaline food products found in processing plants. This prevents the material from corroding or leaching harmful substances into the food, guaranteeing product purity.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it ideal for components like seals, gaskets, and valve seats, where it reduces wear on moving parts and minimizes operational energy needs.

How These Properties Translate to Operational Gains

The technical properties of PTFE deliver tangible benefits that impact a facility's bottom line and safety standards. These advantages are why it is specified for everything from cookware to industrial processing lines.

Increased Productivity and Reduced Waste

The non-stick surface of PTFE-coated transport belts and sheets prevents food from sticking during production. This ensures a smoother workflow, minimizes product waste, and simplifies cleanup between batches.

Enhanced Hygiene and Safety

Because food and other materials do not easily stick to PTFE, it is less prone to bacterial buildup. Its non-wetting nature can even promote a "self-cleaning" effect in some applications, and its chemical inertness ensures it meets stringent FDA requirements for food-contact materials.

Reduced Maintenance and Downtime

Components made from or coated with PTFE have a longer operational lifespan. Their resistance to wear, heat, and chemical corrosion means they need to be replaced less frequently, which significantly reduces costly industrial downtime and maintenance labor.

Understanding the Trade-offs and Limitations

No material is perfect, and being a trusted advisor means acknowledging a material's limitations. Understanding where PTFE falls short is critical for proper application.

Mechanical Weakness in Unfilled State

In its pure, or "unfilled," state, PTFE has relatively low tensile strength and can be susceptible to wear from abrasion. It is much softer than other high-performance polymers like PEEK.

Reinforcement is Often Necessary

To overcome its mechanical limitations, PTFE is often reinforced with fillers like glass fiber, carbon, graphite, or bronze. These additives dramatically improve durability, wear resistance, and reliability in demanding applications like ball valve seats.

Sensitivity to Creep and Abrasion

Under sustained load, PTFE can deform over time—a phenomenon known as "creep." This, combined with its softness, makes pure PTFE unsuitable for high-load structural applications where abrasive forces are present.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is product purity and hygiene: PTFE's extreme chemical inertness and easy-to-clean, non-stick surface are its most critical advantages.

- If your primary focus is improving mechanical efficiency: The exceptionally low friction of PTFE reduces wear on moving parts, but you should specify a reinforced grade for high-load or high-cycle applications.

- If your primary focus is high-temperature processing: PTFE's thermal stability ensures material integrity in baking, frying, and sterilization processes where other polymers would fail.

Ultimately, PTFE provides a uniquely reliable and inert surface, safeguarding both product integrity and operational efficiency in the food and beverage industry.

Summary Table:

| Key PTFE Property | Primary Benefit in Food & Beverage |

|---|---|

| Non-Stick Surface | Prevents product sticking, reduces waste, and simplifies cleaning. |

| High Heat Tolerance | Withstands baking/frying temperatures without degrading. |

| Chemical Inertness | Resists cleaning agents and acids; ensures product purity and FDA compliance. |

| Low Friction | Reduces wear on moving parts, lowering energy needs and maintenance. |

Ready to enhance your production line's efficiency and safety with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right solution, whether you need a prototype or a high-volume order, to meet the stringent demands of the food and beverage industry.

Contact our experts today to discuss how our PTFE solutions can solve your specific challenges and add value to your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers