In short, Polytetrafluoroethylene (PTFE) bars are machined into a vast range of components where chemical resistance, low friction, and high-temperature stability are critical. The most common applications include manufacturing seals, gaskets, bushings, bearings, and chemically inert parts for the food, medical, and semiconductor industries.

The core reason for PTFE's widespread use is its unique combination of properties. Its extreme chemical inertness, exceptionally low coefficient of friction, and high-temperature tolerance make it a premier problem-solving material in environments too harsh for conventional plastics or metals.

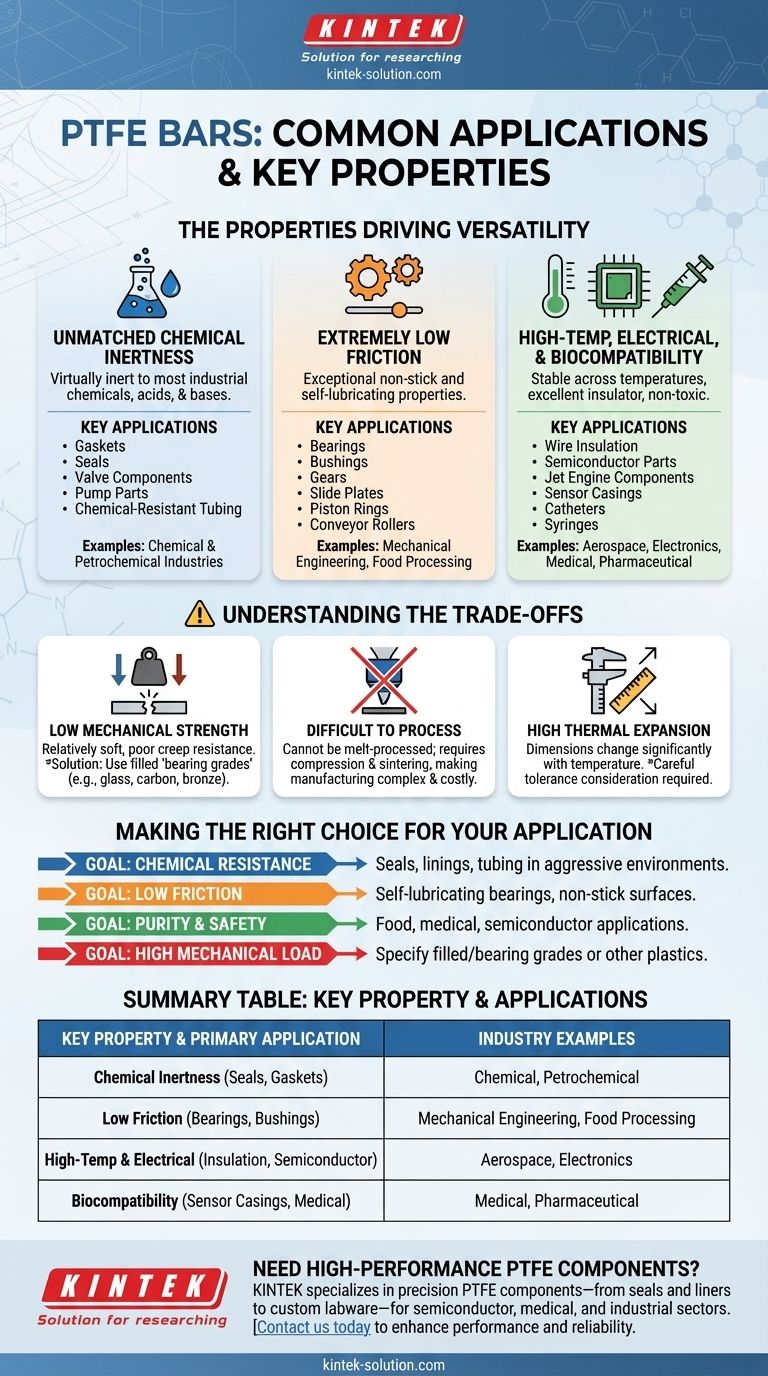

The Properties Driving PTFE's Versatility

To understand where PTFE bars are used, it's essential to first understand why they are chosen. Its utility stems from a few elite characteristics that make it uniquely suitable for demanding jobs.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases.

This property makes it indispensable in the chemical and petrochemical industries for components like gaskets, seals, valve components, pump parts, and chemical-resistant tubing. It ensures the integrity and purity of the process while preventing material degradation.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any known solid material, giving it exceptional non-stick and self-lubricating properties.

This is the key to its use in mechanical engineering for parts like bearings, bushings, gears, slide plates, and piston rings. These components operate smoothly with minimal wear and without the need for external lubricants. This same property is leveraged in food processing for conveyor belt rollers and non-stick surfaces.

High-Temperature and Electrical Resistance

PTFE maintains its stability across a wide temperature range and is an excellent electrical insulator.

This makes it a top choice for high-temperature applications such as components in jet engines or UV lamps. Its dielectric properties are critical for electrical applications, where it is used for wire insulation and components in transformers and semiconductors.

Biocompatibility and Purity

PTFE is non-toxic, biocompatible, and can be produced to high purity standards, making it safe for contact with food and medical products.

This is why it's widely used in the food, beverage, and pharmaceutical industries. Common applications include temperature sensor casings, catheters, syringes, and scientific equipment components where preventing contamination is paramount.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Low Mechanical Strength

Standard PTFE is a relatively soft material with poor creep resistance (the tendency to deform under constant load) and low tensile strength compared to other engineering plastics. For this reason, "bearing grades" are often produced by adding fillers like glass, carbon, or bronze to improve mechanical durability.

Difficult to Process

PTFE cannot be melt-processed like common thermoplastics. It must be formed through a process of compression and sintering, which can make manufacturing more complex and costly.

High Thermal Expansion

The material has a relatively high coefficient of thermal expansion. This means its dimensions can change significantly with temperature, a factor that must be carefully considered when designing components with tight tolerances.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal.

- If your primary focus is chemical resistance: PTFE is an elite choice for seals, linings, and tubing in the most aggressive chemical environments.

- If your primary focus is low friction: It is ideal for self-lubricating bearings, bushings, and non-stick surfaces where maintenance is difficult.

- If your primary focus is purity and safety: Its inert and non-toxic nature makes it a standard in food, medical, and semiconductor applications.

- If your primary focus is high mechanical load: You should specify a filled or "bearing grade" of PTFE or evaluate other engineering plastics entirely.

Ultimately, PTFE is the material of choice for solving engineering challenges where performance under extreme conditions is non-negotiable.

Summary Table:

| Key Property | Primary Application | Industry Examples |

|---|---|---|

| Chemical Inertness | Seals, Gaskets, Valve Parts | Chemical, Petrochemical |

| Low Friction | Bearings, Bushings, Slide Plates | Mechanical Engineering, Food Processing |

| High-Temp & Electrical Resistance | Wire Insulation, Semiconductor Parts | Aerospace, Electronics |

| Biocompatibility | Sensor Casings, Catheters, Syringes | Medical, Pharmaceutical |

Need High-Performance PTFE Components?

KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert fabrication with rigorous quality control, delivering solutions tailored to your unique requirements, whether for prototypes or high-volume orders.

Contact us today to discuss how our PTFE expertise can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components