For throttle valves, RPTFE (Reinforced Polytetrafluoroethylene) is the preferred material in industries where product purity and chemical resistance are non-negotiable. It is particularly suitable for applications within the food, dairy, pharmaceutical, and chemical processing sectors due to its unique combination of inertness and durability.

The core reason RPTFE is specified for these critical industries is its ability to provide the exceptional chemical inertness of PTFE while adding the mechanical strength needed to withstand the physical stresses of fluid control systems.

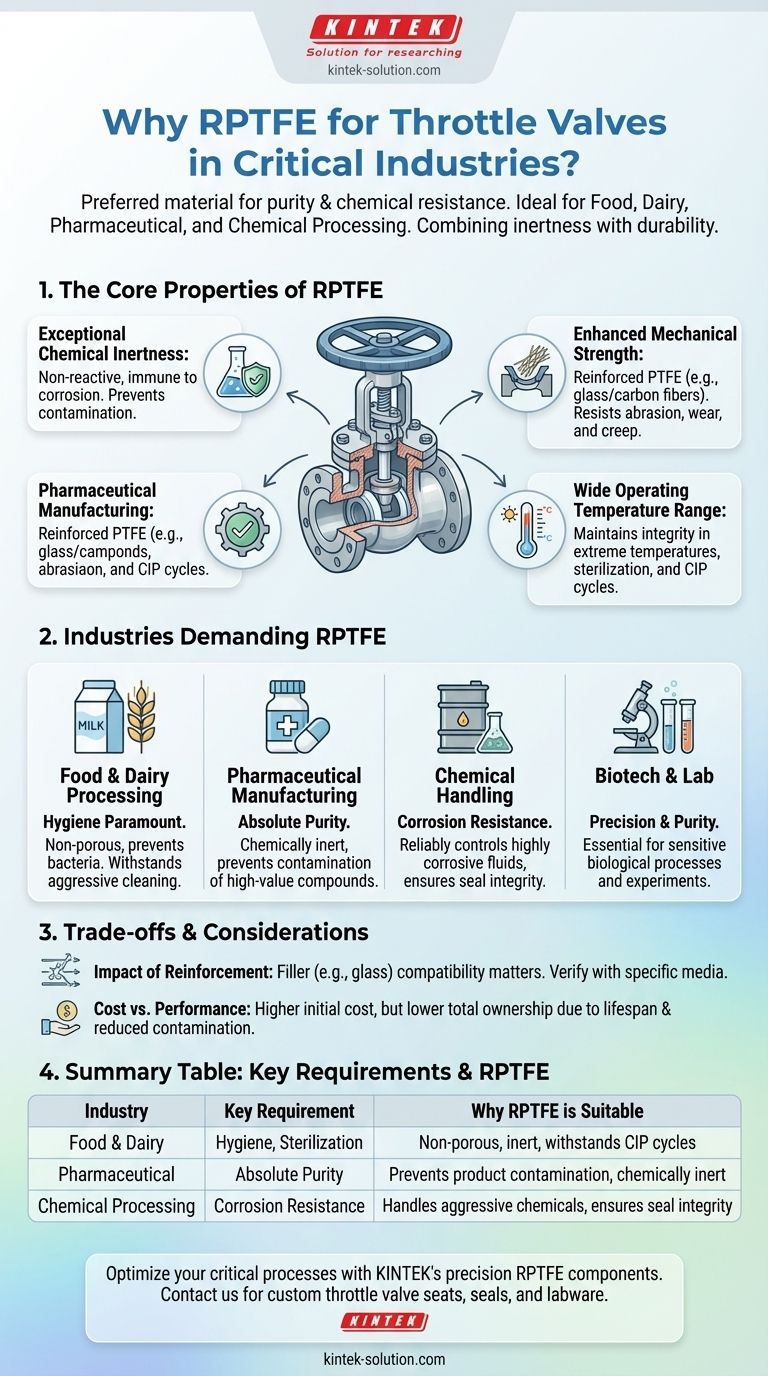

The Core Properties Driving RPTFE Adoption

To understand why RPTFE is a superior choice, we must first look at its fundamental characteristics. The material isn't chosen by accident; it's selected because its properties solve specific, critical challenges.

Exceptional Chemical Inertness

RPTFE inherits its non-reactive nature from its base polymer, PTFE. This makes it virtually immune to corrosion from the vast majority of industrial chemicals.

This property is essential for preventing contamination, ensuring that the valve material does not leach into or react with the media it is controlling.

Enhanced Mechanical Strength

The "R" in RPTFE stands for reinforced. Fillers, typically glass or carbon fibers, are added to the PTFE matrix.

This reinforcement significantly improves the material's resistance to abrasion, deformation under load (creep), and wear, making it far more durable than standard PTFE in demanding valve applications.

Wide Operating Temperature Range

RPTFE maintains its structural integrity and performance characteristics across a broad spectrum of temperatures.

This stability is vital for processes that involve sterilization, cleaning-in-place (CIP) cycles, or handling fluids at extreme temperatures.

Why These Industries Demand RPTFE

The specific operational demands of certain industries align perfectly with the benefits of RPTFE. For them, it is not just a good choice, but often the necessary one.

Food and Dairy Processing

In the food and dairy industries, hygiene is paramount. RPTFE's non-porous and non-reactive surface prevents product contamination and the buildup of bacteria.

Its durability also allows it to withstand aggressive, high-temperature cleaning and sterilization agents used in these facilities.

Pharmaceutical Manufacturing

The pharmaceutical sector requires absolute product purity. Any material in contact with the product must be completely inert.

RPTFE provides this assurance, ensuring that sensitive and high-value pharmaceutical compounds remain unadulterated throughout the manufacturing process.

Chemical Handling

For the chemical industry, equipment longevity and safety are key concerns. Throttle valves must reliably control highly corrosive or reactive fluids.

RPTFE's broad chemical resistance ensures the valve seat maintains its seal integrity, preventing dangerous leaks and costly downtime.

Understanding the Trade-offs

While RPTFE is a high-performance material, no solution is without its considerations. An objective analysis requires acknowledging its limitations.

The Impact of Reinforcement Material

The choice of filler material matters. While glass is common, it can be attacked by a few specific chemicals, such as hydrofluoric acid or strong hot caustics.

For these niche applications, a different filler (like carbon) or an alternative material might be necessary. Always verify chemical compatibility against your specific media.

Cost vs. Performance

RPTFE is a premium material and is more expensive than common elastomers or standard PTFE.

However, its superior lifespan, reduced maintenance needs, and the prevention of costly product contamination often provide a much lower total cost of ownership in critical applications.

Making the Right Choice for Your Application

Selecting the correct valve material depends entirely on your operational priorities.

- If your primary focus is product purity (food, pharma, biotech): RPTFE is the industry standard for preventing contamination and ensuring material inertness.

- If your primary focus is handling aggressive chemicals: RPTFE offers a robust and reliable sealing solution for a wide range of corrosive media where lesser materials would fail.

- If your primary focus is mechanical durability and high-cycle use: The reinforcement in RPTFE provides the necessary strength to resist wear and deformation, ensuring a longer service life.

Ultimately, choosing RPTFE for throttle valves is an investment in reliability, safety, and purity for your most critical processes.

Summary Table:

| Industry | Key Requirement | Why RPTFE is Suitable |

|---|---|---|

| Food & Dairy | Hygiene, Sterilization | Non-porous, inert, withstands CIP cycles |

| Pharmaceutical | Absolute Purity | Prevents product contamination, chemically inert |

| Chemical Processing | Corrosion Resistance | Handles aggressive chemicals, ensures seal integrity |

Optimize your critical processes with KINTEK's precision RPTFE components.

For industries where product purity and chemical resistance are non-negotiable, KINTEK manufactures high-performance PTFE and RPTFE components—including custom throttle valve seats, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with a focus on precision production, from prototypes to high-volume orders.

Contact us today to discuss how our custom RPTFE solutions can enhance the reliability, safety, and longevity of your throttle valves and other fluid control systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

People Also Ask

- What are the manufacturing differences between PTFE and elastomer lip seals? A Guide to Performance and Cost

- What are typical applications of TFE Encapsulated Gaskets? Ideal for Chemical & High-Purity Seals

- What are the benefits of using EPTFE joint sealant? Achieve Superior Sealing for Demanding Applications

- What are the benefits of using PTFE gaskets? Superior Sealing for Extreme Conditions

- What industries commonly use PTFE bushings? Critical Applications in Chemical, Automotive, and Medical

- What are the color differences between PTFE and graphite packing? Select the Right Material for Your Application

- What is the composition of graphite packing? The Science Behind a High-Performance Seal

- How does bearing pressure affect the coefficient of friction in PTFE slide bearings? Maximize Performance with Higher Loads