At its core, Polytetrafluoroethylene (PTFE) is one of the most versatile and reliable sealing materials available for demanding industrial environments. Its suitability stems from a unique combination of three primary characteristics: near-total chemical inertness, an exceptionally wide operating temperature range, and an extremely low coefficient of friction. These properties ensure a stable, non-contaminating, and durable seal where many other materials would quickly fail.

While individual properties like chemical or heat resistance are impressive, the true value of PTFE gaskets lies in their ability to deliver all these benefits simultaneously. This synergy creates a highly reliable seal that reduces maintenance costs and operational downtime in the harshest conditions.

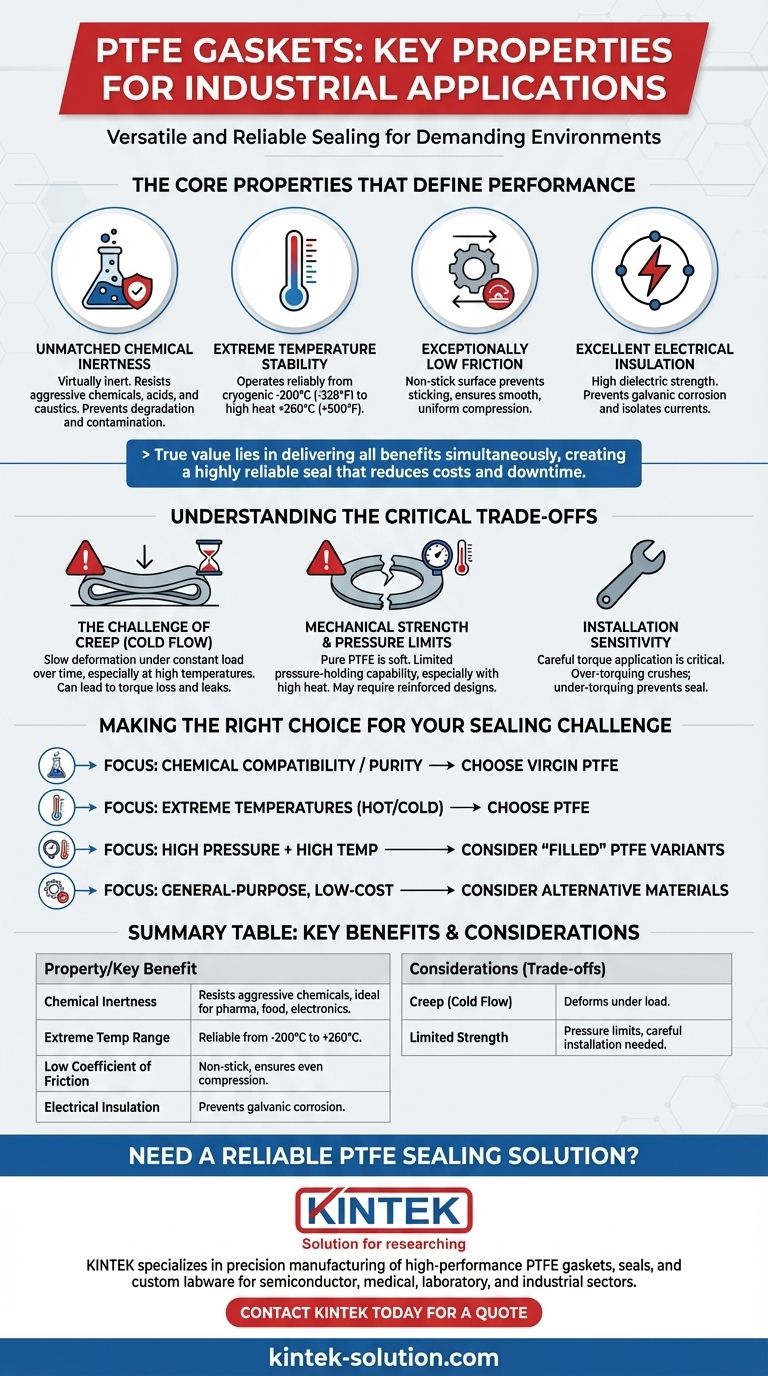

The Core Properties That Define PTFE Performance

To understand why PTFE is specified for critical applications, it's essential to break down how each of its core properties translates into tangible, real-world benefits.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and caustics. This makes it the default choice for services handling aggressive media.

This inertness prevents the gasket from degrading, swelling, or leaching, which protects the integrity of the seal and prevents contamination of the process fluid. This is critical in high-purity industries like pharmaceuticals, food and beverage, and electronics.

Extreme Temperature Stability

PTFE maintains its integrity and sealing properties across an exceptionally broad thermal spectrum, typically from cryogenic temperatures of -200°C (-328°F) up to +260°C (+500°F).

This thermal stability makes it one of the few materials that can perform reliably in applications involving extreme cold, such as LNG processing, or high heat, like in chemical reactors and steam lines.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a characteristic "slippery" or non-stick surface.

This property provides two key advantages. First, it prevents materials from sticking to the gasket, which is useful in food or viscous media processing. Second, it allows for a smooth, uniform compression during bolt-up, ensuring even stress distribution across the flange face.

Excellent Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It does not conduct electricity.

While not always the primary reason for selection, this property is crucial in applications where flanges must be electrically isolated to prevent galvanic corrosion between dissimilar metals or to interrupt electrical currents.

Understanding the Critical Trade-offs of PTFE

No material is perfect, and being an objective advisor means acknowledging a material's limitations. Understanding the trade-offs of PTFE is key to using it effectively.

The Challenge of Creep (Cold Flow)

The most significant limitation of pure PTFE is its tendency to creep, or "cold flow." This is the process where the material slowly deforms over time under the pressure of a constant load, such as a bolted flange.

This deformation can lead to a loss of bolt torque and a reduction in sealing stress, potentially resulting in a leak long after the initial installation. This is especially pronounced at higher temperatures.

Mechanical Strength and Pressure Limits

Compared to metals or even some reinforced gasket materials, pure PTFE is relatively soft. Its pressure-holding capability is limited by its mechanical strength and its resistance to creep.

For this reason, pure PTFE gaskets are not always suitable for extremely high-pressure services, especially when combined with high temperatures, unless they are incorporated into a reinforced design (e.g., filled PTFE or jacketed gaskets).

Installation Sensitivity

Due to its softness and potential for creep, PTFE gasket installation requires careful attention. Over-torquing can easily crush the gasket and initiate premature failure, while under-torquing won't provide enough stress to create an effective initial seal. Following manufacturer torque specifications is critical.

Making the Right Choice for Your Sealing Challenge

Selecting the right gasket requires balancing performance requirements with material limitations. PTFE is a powerful tool when applied correctly.

- If your primary focus is chemical compatibility or process purity: Virgin PTFE is almost always the superior choice due to its near-total inertness.

- If your primary focus is extreme temperatures (hot or cold): PTFE's wide operating range makes it one of the few plastics capable of handling both cryogenic and high-heat conditions.

- If your primary focus is high pressure combined with high temperature: Be mindful of creep in pure PTFE and consider "filled" PTFE variants, which add materials like glass or carbon to improve mechanical strength and creep resistance.

- If your primary focus is a general-purpose, low-cost utility service: A standard non-asbestos or elastomer gasket may be more cost-effective if the chemical and thermal demands are low.

Ultimately, understanding both the exceptional strengths and the inherent limitations of PTFE empowers you to deploy it where it will provide the most value and long-term reliability.

Summary Table:

| Property | Key Benefit for Industrial Applications |

|---|---|

| Chemical Inertness | Resists virtually all aggressive chemicals, ideal for pharmaceuticals, food & beverage, and electronics. |

| Extreme Temperature Range | Performs reliably from -200°C to +260°C, suitable for cryogenics and high-heat processes. |

| Low Coefficient of Friction | Non-stick surface prevents material build-up and ensures even compression during installation. |

| Excellent Electrical Insulation | Prevents galvanic corrosion and interrupts electrical currents between flanges. |

| Considerations (Trade-offs) | Creep (Cold Flow) and limited mechanical strength at high pressure/temperature; requires careful installation. |

Need a reliable PTFE sealing solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including gaskets, seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the material's full benefits—unmatched chemical resistance, thermal stability, and purity—while expertly managing its limitations through superior design and fabrication.

Whether you require a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures a perfect seal that enhances reliability and reduces downtime.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application