At their core, PTFE slide plates are high-performance bearings engineered to create a low-friction surface between structural elements. Their primary purpose is to allow for controlled, smooth movement, safely accommodating forces like thermal expansion and contraction in large structures such as pipelines, bridges, and industrial equipment.

The crucial insight is that large structures are not static; they need to move. PTFE slide plates are not simply "slippery pads" but essential engineering components that prevent the build-up of destructive stress by transforming immense forces into manageable, silent motion.

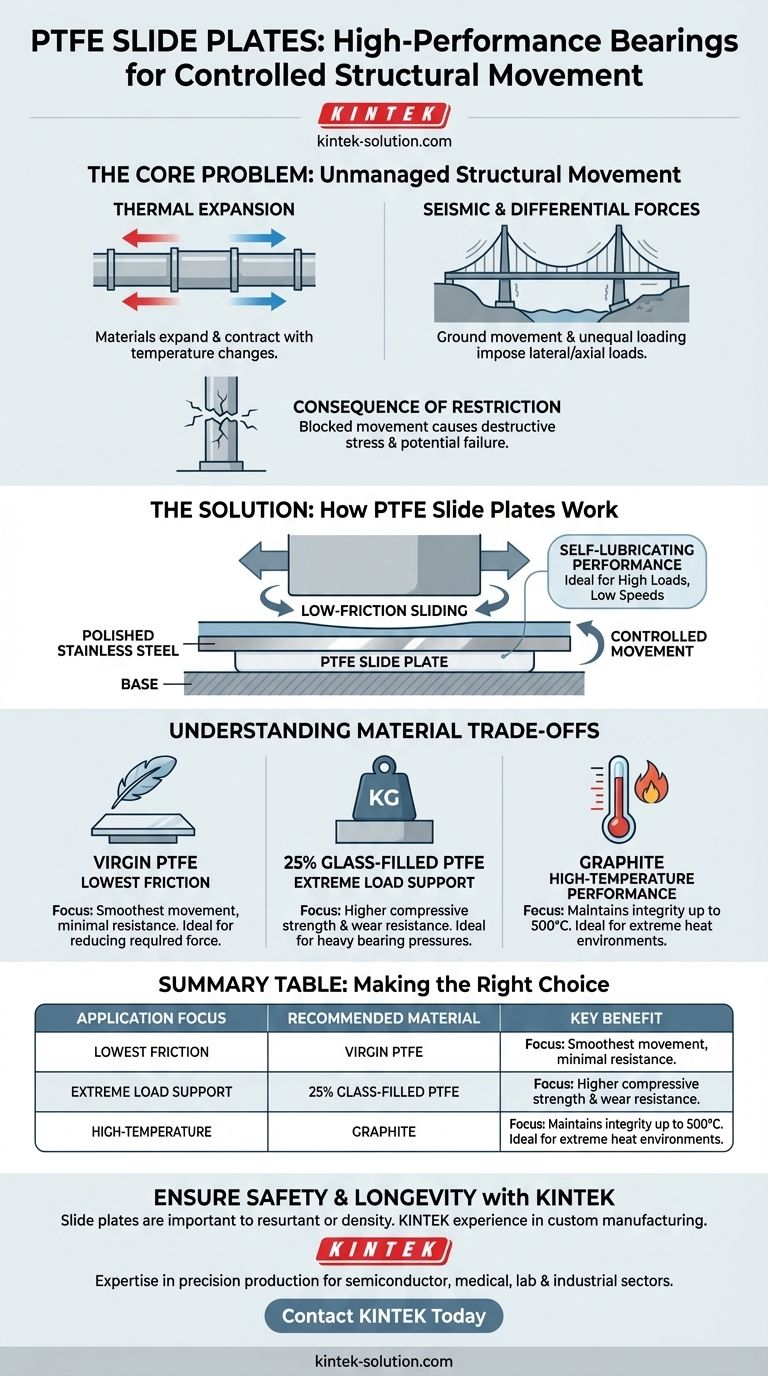

The Core Problem: Unmanaged Structural Movement

Large-scale infrastructure and equipment are constantly subjected to powerful forces that cause them to shift, expand, and contract. If this movement is restricted, the resulting stress can lead to catastrophic failure.

Thermal Expansion and Contraction

Materials, especially metals used in pipelines and bridges, expand when heated and contract when cooled. Over hundreds of feet of steel, a change in ambient temperature can translate into inches of movement that must be safely accommodated.

Seismic and Differential Forces

Beyond temperature, forces from ground movement, seismic activity, or the uneven settling of foundations can impose lateral and axial loads on a structure.

The Consequence of Restriction

When this natural movement is blocked, the structure is put under immense internal stress. This can cause pipelines to buckle, support columns to crack, and bridge girders to fail, compromising the integrity and safety of the entire system.

How PTFE Slide Plates Provide the Solution

PTFE slide plates are designed to decouple a structure from its foundation or another structural element, allowing controlled movement and dissipating stress.

The Principle of Low-Friction Sliding

The key is the exceptionally low coefficient of friction of Polytetrafluoroethylene (PTFE), especially when sliding against a polished surface like stainless steel. This allows massive loads to move with minimal resistance.

Self-Lubricating Performance

These bearings are most effective under high loads and low speeds, which is typical for structural movement. Their self-lubricating properties mean they function reliably for years without maintenance, unlike traditional greased mechanical bearings.

Critical Applications

This technology is fundamental in sectors where structural integrity is paramount. Common uses include petrochemical plants, heavy machinery mounts, pipelines, buildings, and bridge girders.

Understanding the Material Trade-offs

The specific composition of a slide plate is chosen based on the precise demands of the application. The choice involves balancing friction, load capacity, and temperature resistance.

Virgin PTFE on Stainless Steel

This combination offers the lowest coefficient of friction. It is the ideal choice when minimizing the force required for movement is the top priority.

25% Glass-Filled PTFE

Adding glass fibers to the PTFE significantly increases its compressive strength and wear resistance. This makes it suitable for applications with higher bearing pressures, though it comes with a marginal increase in friction.

Graphite on Stainless Steel

For high-temperature applications up to 500°C, graphite is used as the sliding material. Standard PTFE would begin to degrade at these temperatures, making graphite the only viable option for certain industrial processes.

Making the Right Choice for Your Application

Selecting the correct slide plate is a critical engineering decision based on the primary operational demand.

- If your primary focus is the lowest possible friction: Virgin PTFE on stainless steel is the standard for smooth, low-resistance movement.

- If your primary focus is supporting extreme weight: 25% glass-filled PTFE provides the necessary compressive strength for higher bearing loads.

- If your primary focus is high-temperature performance: Graphite-based slide plates are engineered to maintain their integrity in extreme heat environments.

Ultimately, these simple components are fundamental to the safety and longevity of our most critical infrastructure.

Summary Table:

| Application Focus | Recommended Material | Key Benefit |

|---|---|---|

| Lowest Friction | Virgin PTFE on Stainless Steel | Smoothest movement with minimal resistance |

| Extreme Load Support | 25% Glass-Filled PTFE | Higher compressive strength and wear resistance |

| High-Temperature Performance | Graphite on Stainless Steel | Maintains integrity in environments up to 500°C |

Ensure the Safety and Longevity of Your Critical Infrastructure

Choosing the right slide plate is a precise engineering decision. KINTEK specializes in manufacturing high-performance PTFE components, including custom slide plates, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your components meet exact specifications for load, friction, and temperature requirements.

Let us help you engineer a solution that manages structural movement safely and reliably. Contact KINTEK today to discuss your project needs, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What material is used to make PTFE flange gaskets? Choose the Right PTFE for Your Sealing Needs

- What considerations are important for successful PTFE CNC machining? Master Precision with a Finesse-Over-Force Approach

- How can deformation of PTFE during machining be minimized? Master Precision with Sharp Tools & Thermal Control

- How does surface finish impact PTFE sheet performance? A Guide to Optimizing for Your Application

- What are the differences in installation and maintenance between spiral and split PTFE backup rings? A Guide to Maximizing Performance and Minimizing Downtime

- Can you provide an example comparing PTFE and PTFE envelope gaskets in a practical scenario? Ensure a Reliable Seal in Demanding Applications

- What is the conclusion regarding PTFE bellows as a material choice? Prioritize Chemical Inertness and Flexibility

- What are the pressure limitations for PTFE ball valve seats? Understanding the Critical Role of Valve Size